Process for preparing degradable polyester microsphere wrapping nano insulin

A technology for degrading polyester and insulin, used in medical preparations containing active ingredients, devices that make medicines into special physical or taking forms, and drug combinations, which can solve the problems of no insulin nanoparticles and high toxicity. , to improve the efficiency of drug delivery, reduce the probability of denaturation, and reduce the effect of drug burst release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Different types of polylactic acid are used as materials, and the method of the invention is used to prepare drug-loaded microspheres.

[0031] 1) Preparation of insulin nanoparticles: Weigh 100mg of insulin raw material and dissolve it in 100mL of water with pH=2.5, drop 0.1M NaOH solution into it to pH=5.3; let the above suspension stand still, and wait for the insulin nanoparticles to settle in the lower layer The supernatant was removed, and the concentrated insulin nanoparticle suspension (about 10 mL) in the lower layer was frozen and solidified in liquid nitrogen, and freeze-dried for 24 hours to obtain a solid powder of insulin nanoparticles;

[0032] 2) Preparation of emulsion system: Weigh 40 mg of insulin nanoparticles obtained in step 1) and 360 mg of different types of PLGA, add 18 mL of solvent DMF to it, and stir until the polymer is dissolved; add this DMF solution to corn containing 1.8 g of Span 83 In 180mL of oil, emulsify under 3000rpm high-speed shear...

Embodiment 2

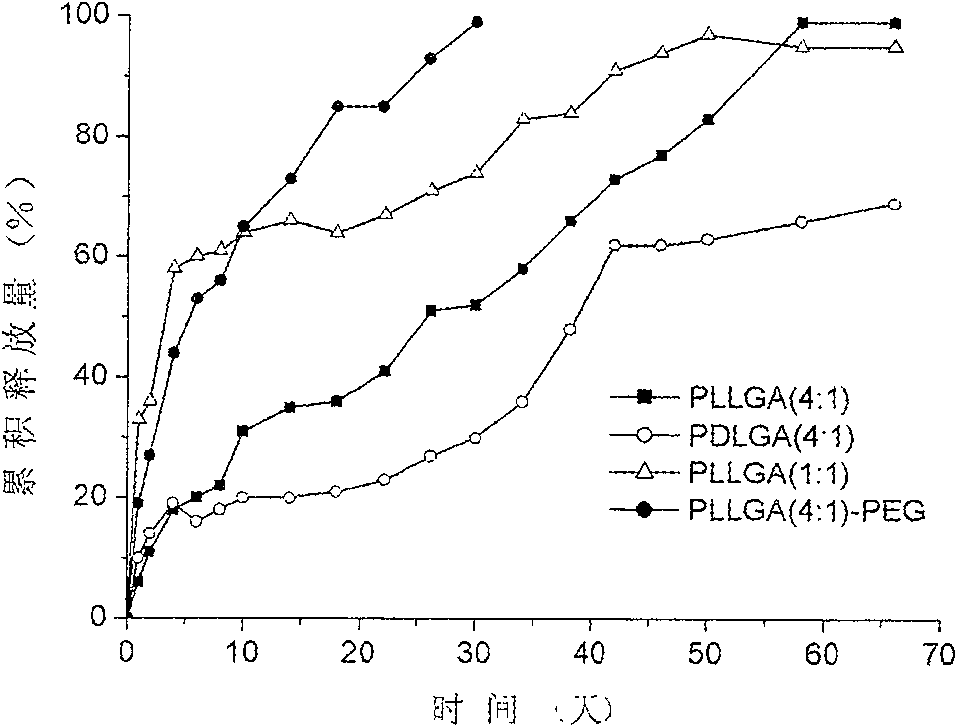

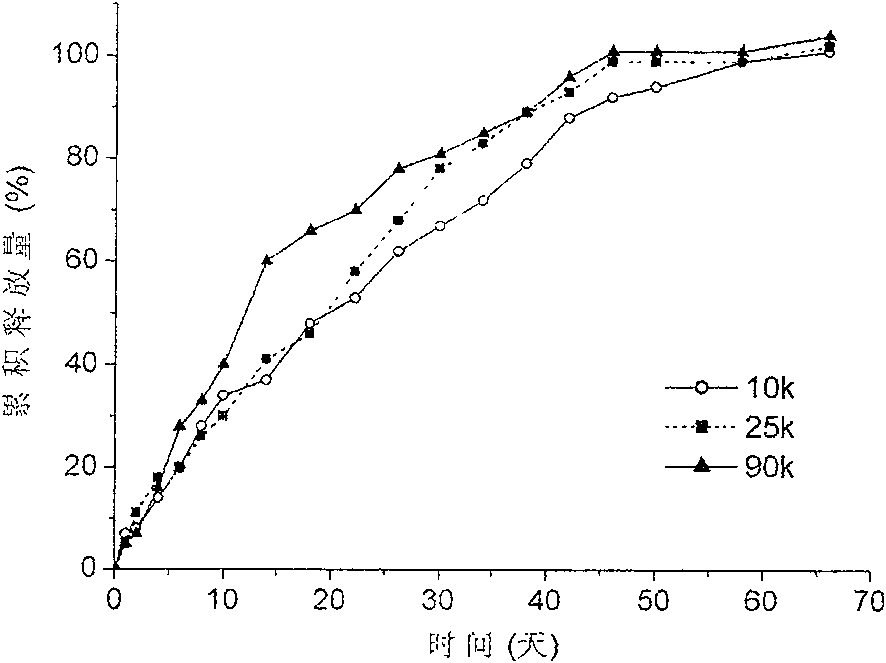

[0039] In vitro release evaluation of insulin-encapsulated microspheres prepared by different kinds of polylactic acid materials.

[0040] Weigh 100 mg of the insulin-loaded microspheres prepared in Example 1, place them in a centrifuge tube, add 10 mL of Tris-HCl buffer, shake at a constant temperature at 37 ° C, centrifuge after a certain time interval, take 2 mL of the supernatant to be tested, and simultaneously Add an equal volume of fresh buffer and continue shaking. Insulin concentration in the supernatant was determined by BCA kit. The release behavior of the microspheres was measured in figure 1 .

Embodiment 3

[0042] Using PLLGA(1:1)30k as material, the method of the present invention is used to prepare drug-loaded microspheres.

[0043] 1) Preparation of insulin nanoparticles: Weigh 100mg of insulin raw material and dissolve it in 200mL of water with pH=2.7, drop 0.1M NaOH solution into it to pH=5.4; let the above suspension stand, and wait for the insulin nanoparticles to settle in the lower layer Remove the supernatant, place the concentrated insulin nanoparticle suspension in the lower layer in liquid nitrogen to freeze and solidify, and freeze-dry for 24 hours to obtain insulin nanoparticles;

[0044] 2) Preparation of emulsion system: Weigh 7.4, 18.9, 40 mg of insulin nanoparticles and 360 mg of PDLGA (4:1) 10k obtained in step 1) respectively, add 12 mL of solvent DMF to it, and stir until the polymer dissolves; add this DMF solution In 120 mL of corn oil containing 1.2 g of Span 83, emulsify for 5 minutes under high-speed shear at 3000 rpm to prepare a dual-organic emulsion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com