Power supply system of direct liquid fuel battery and its operation method

A liquid fuel cell and power system technology, applied in fuel cells, fuel cell additives, fuel cell components, etc., can solve problems such as system complexity, and achieve the effect of being easy to carry and preventing reverse voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

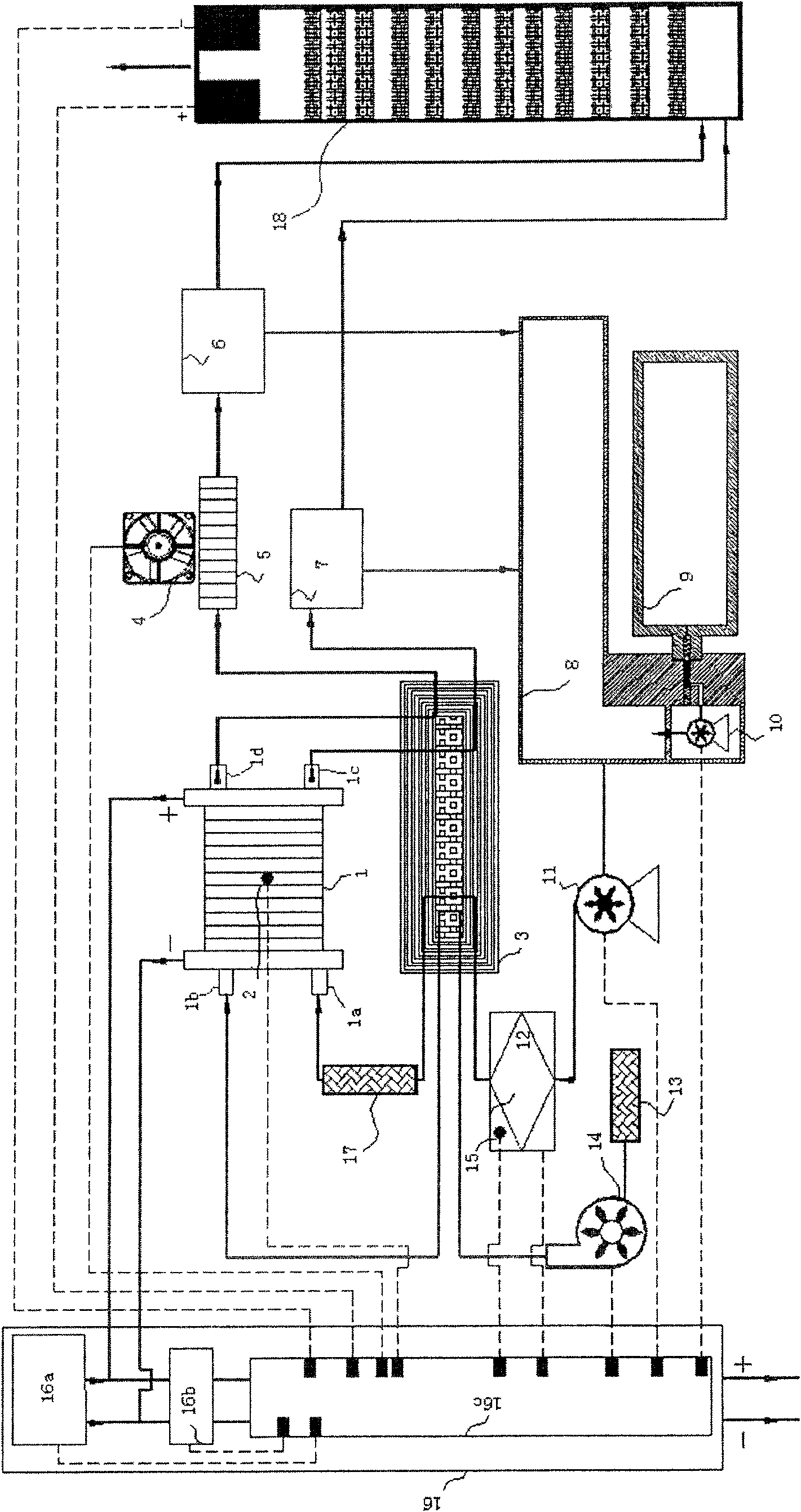

[0033] The principle of the power supply system of the present invention is as follows: figure 1 As shown, it includes: fuel cell main body, fuel supply part, oxidant supply part and control unit part, and the machine entity is shown in Figure 5.

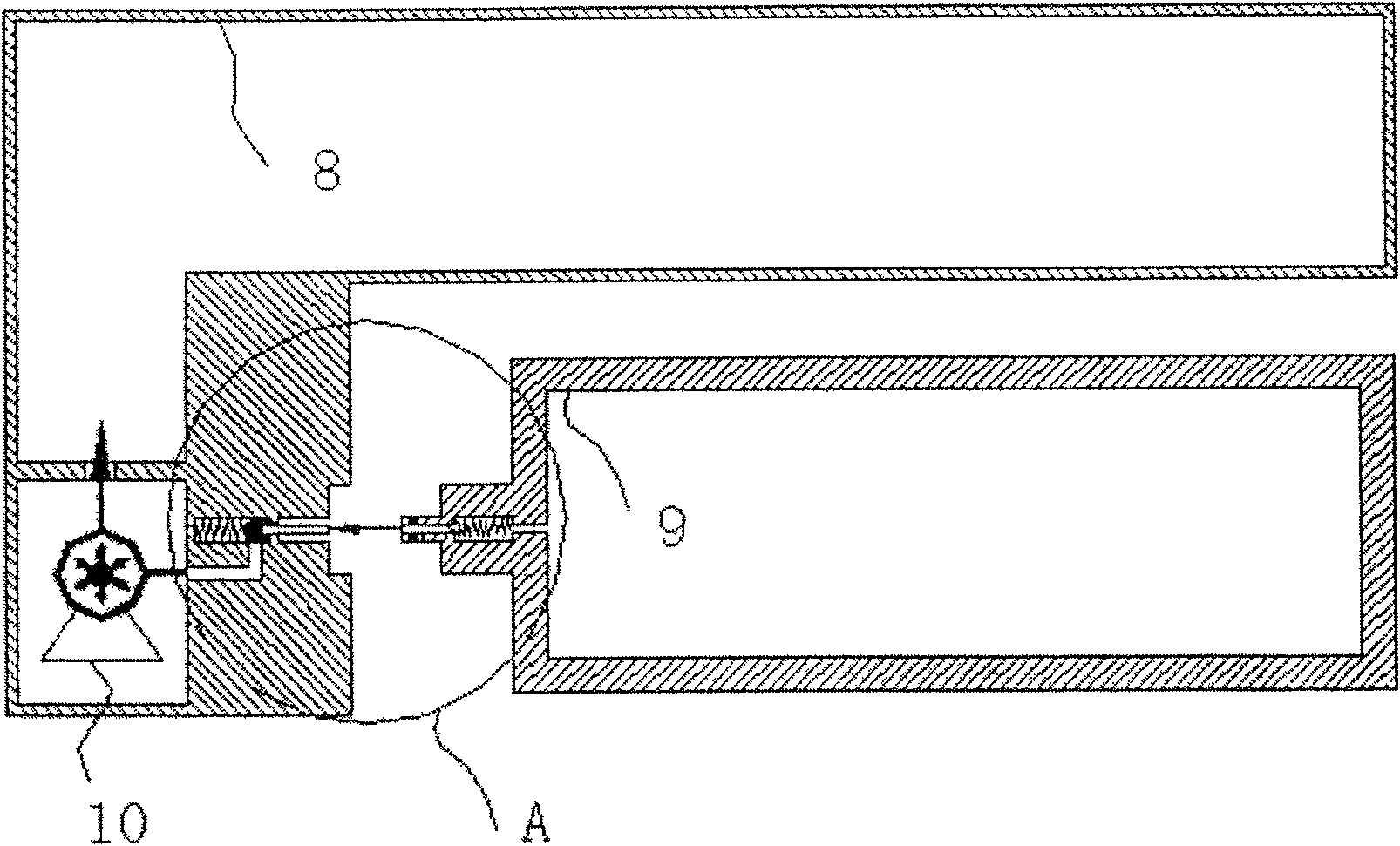

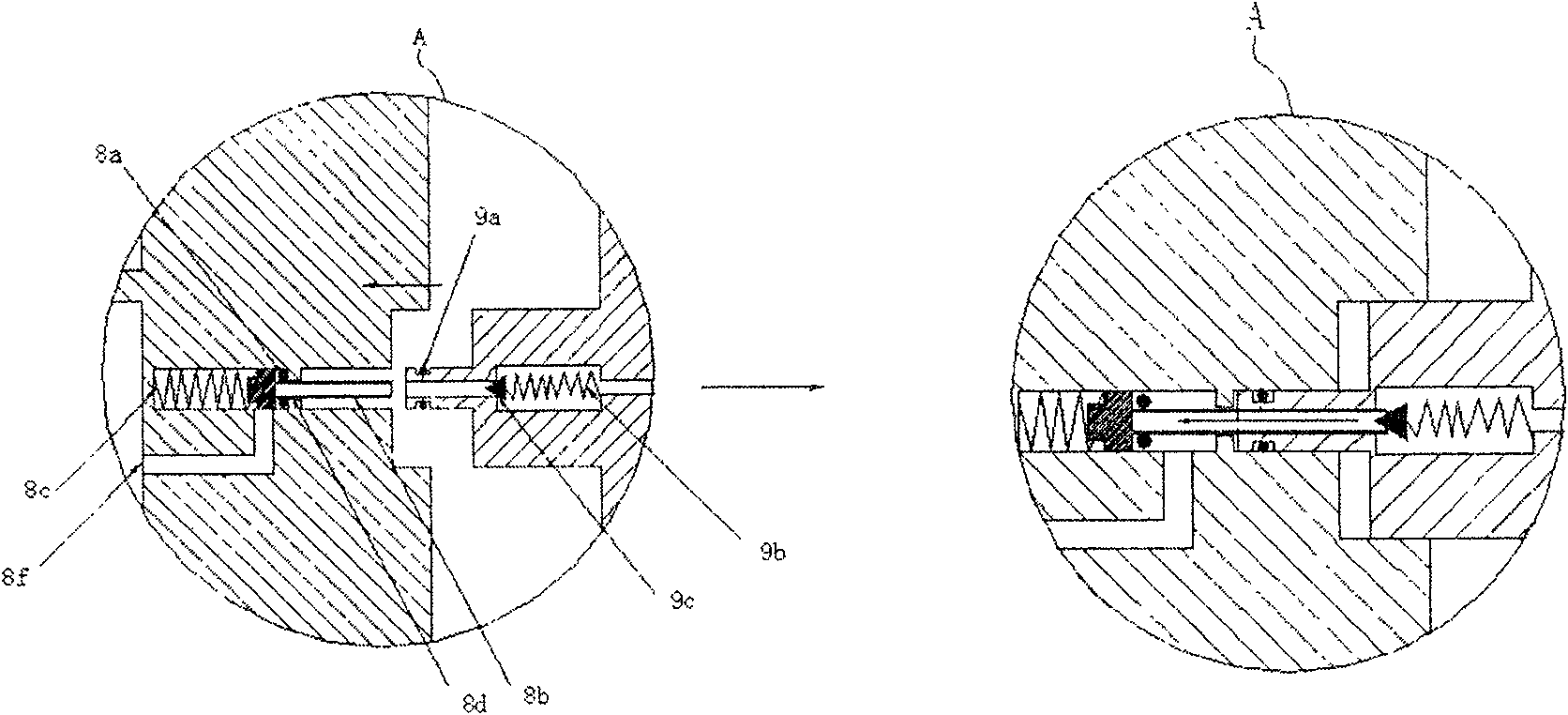

[0034]The high-concentration second liquid fuel starts from the high-concentration liquid fuel cartridge 9 and enters the mixing tank 8 through the micro-metering pump 10 to be mixed with the low-concentration fuel to form the first liquid fuel, and then passes through the micro-channel heat under the action of the fuel circulation pump 11. The exchanger 3 is preheated, and then enters the stack 1 through the filter 17 (mainly cation exchange resin); the air first passes through the filter 13 and the air pump or blower 14, and is also preheated by the microchannel heat exchanger 3 , also enters the fuel cell stack 1. In a fuel cell fuel and oxidant react on the membrane electrode assembly to generate electricity and heat. Both th...

Embodiment 2

[0043] The joint test of the direct methanol fuel cell power supply system of the present invention and the notebook computer, such as Figure 6 shown. A plurality of digital voltmeters 23 and ammeters 22 are connected in the fuel cell power supply system 19 to measure the fuel cell output, the backup battery output and the power consumed by the notebook computer 24 respectively. Their data are monitored at any time by a recording computer 21 . Since the notebook computer 24 belongs to a wide-range voltage input load (9-22V), the electric stack 1 and the backup battery in this system do not go through the power conversion circuit after being mixed, but switch to the direct external output gear, which reduces the power of the circuit itself. consumption.

[0044] In the second embodiment, the methanol concentration is controlled at about 0.5M, the battery temperature is set at 85°C, and the peak power of the fuel cell can reach more than 35W. The front end is the start-up ph...

Embodiment 3

[0046] The direct liquid fuel cell power supply system of the present invention is used as a multifunctional power supply (see Figure 8 ). For constant voltage input loads, the electric stack 1 and the backup battery in the system must be switched to pass through the power conversion circuit 16b and then output to the outside after being mixed. The power supply system 19 can be set as a portable power supply for a 12V or 3.3V constant voltage load 20 after voltage conversion.

[0047] The output voltage is set to 12V, and the output current is set to 0.5A. In the present embodiment, the concentration of methanol is controlled at 0.25M in the test process of nearly 10 hours (see Figure 8 , wherein 21 is a recording computer; 22 is an ammeter; 23 is a voltmeter), the voltage of the stack 1 is stable at about 18.5V, because the output power is small, the output voltage of the stack is relatively high, and the stack 1 is fully connected by the stack 1 during the connection per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com