Desulfurized hydrated coking slurry formula and its production

A water coke slurry, desulfurized water technology, applied in the petroleum industry, liquid carbonaceous fuel, fuel and other directions, can solve the problem of not providing water coke slurry, etc., achieve good fluidity and stability, reduce pollution, and use less. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

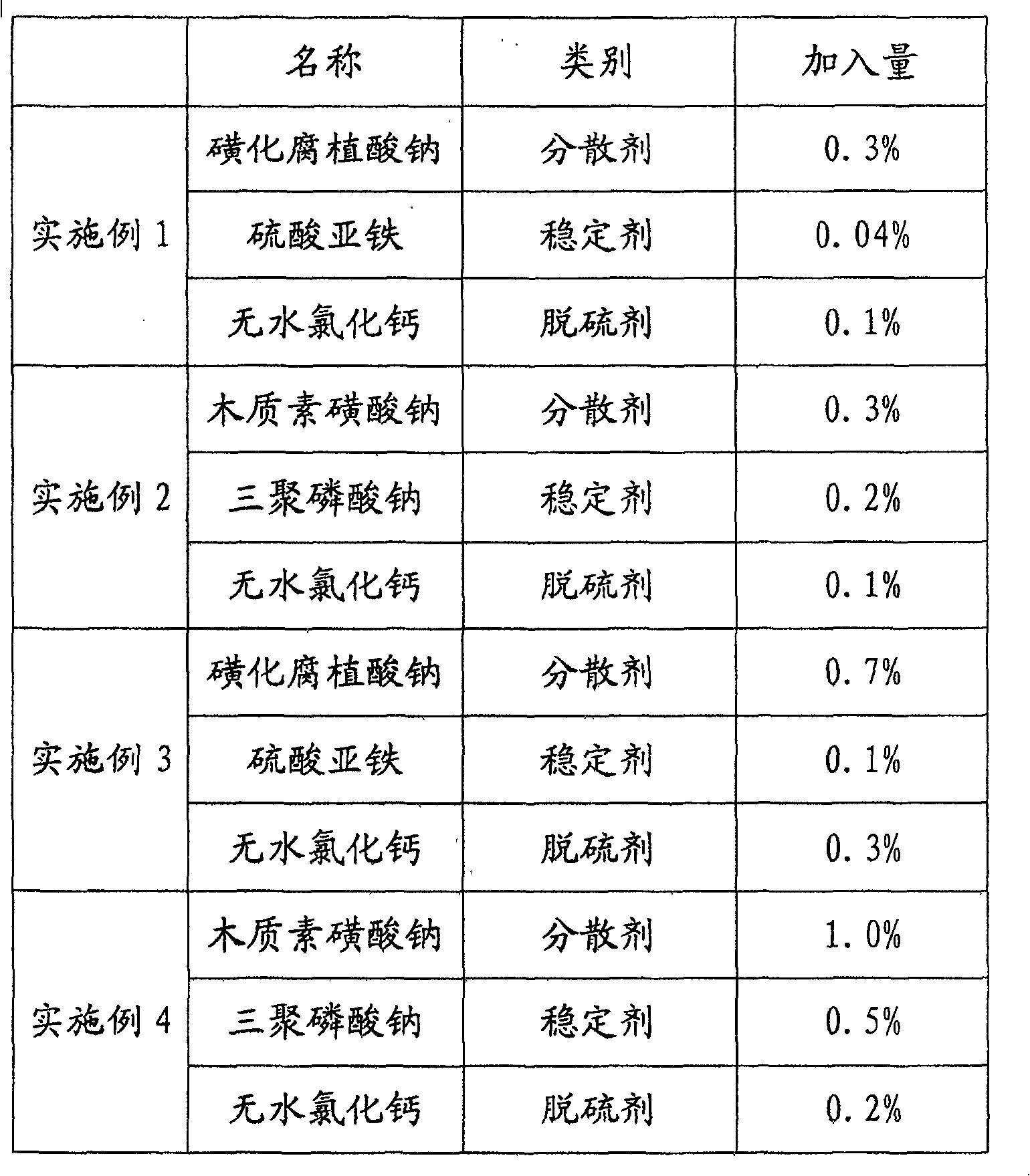

[0028] Water coke slurry was prepared according to the mass percentage of petroleum coke: water: additive = 65.5: 34: 0.44, wherein, the specific content of each component in the additive is shown in Table 1.

[0029] Table 1

[0030]

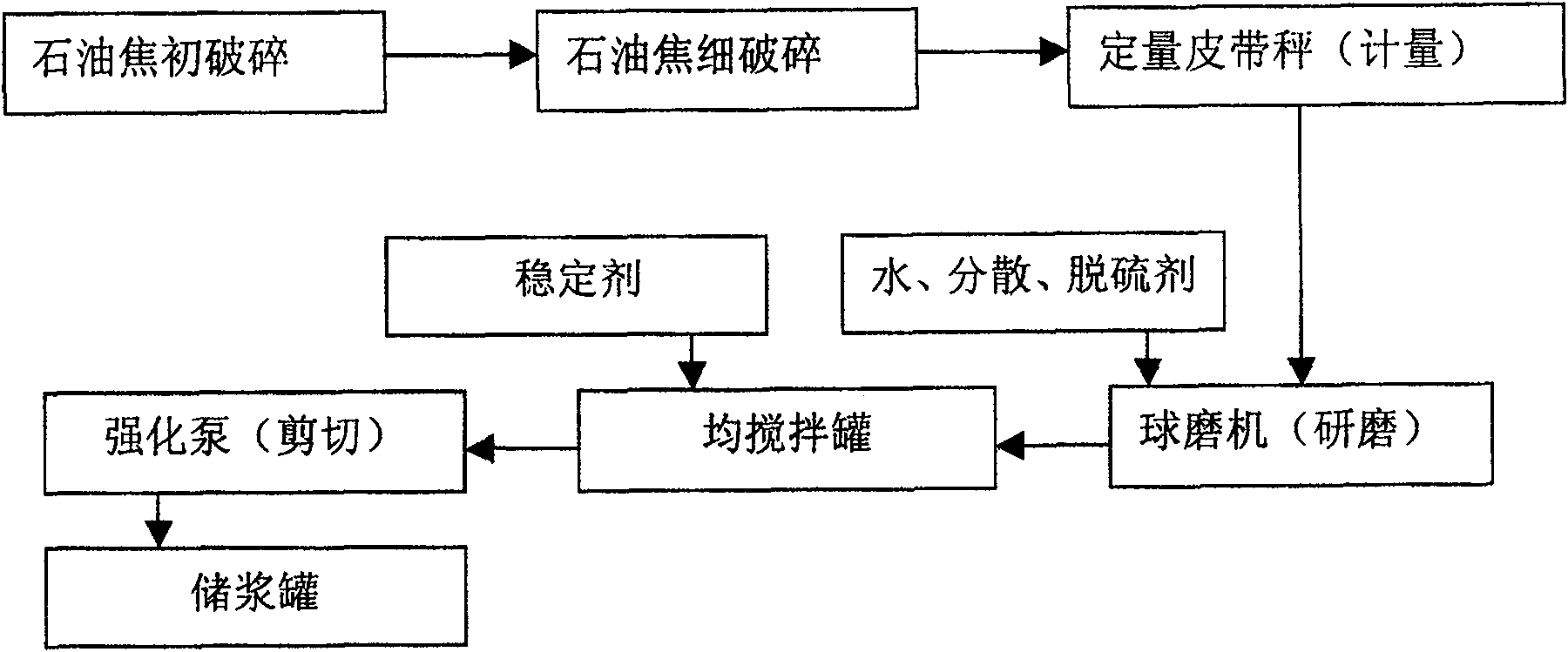

[0031] For the preparation process of the above-mentioned water coke slurry, please refer to figure 1 The pulping process flow chart shown, its specific process is:

[0032] (1) Carry out a mechanical crushing of lump petroleum coke to particle size 8mm;

[0033] (2) Transport the once-broken petroleum coke to the crusher with a belt conveyor for secondary crushing to reach a powder with a particle size of 2mm;

[0034] (3) The pulverized petroleum coke is transported to the belt scale for continuous weighing by a belt conveyor;

[0035] (4) Add additives (dispersant and desulfurizer) and water into the ball mill through the weighed petroleum coke powder in proportion to carry out continuous wet ball milling;

[0036] (5) Petroleum coke ...

Embodiment 2

[0049] Water coke slurry was prepared according to the mass percentage of petroleum coke: water: additive = 65.4: 34: 0.6, wherein the specific content of each component in the additive used was shown in Table 1, and the preparation process was the same as in Example 1.

Embodiment 3

[0051] Water coke slurry was prepared according to the mass percentage of petroleum coke: water: additive = 60.9: 38: 1.1, wherein the specific content of each component in the additive used was shown in Table 1, and the preparation process was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com