Particle diameter selecting pouring procedure of concrete aggregate for thermal insulation wall

A concrete aggregate and thermal insulation wall technology, applied to walls, buildings, building components, etc., can solve problems such as difficult coordination and processing, and achieve the effects of low cost of use, easy installation and disassembly, and good construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

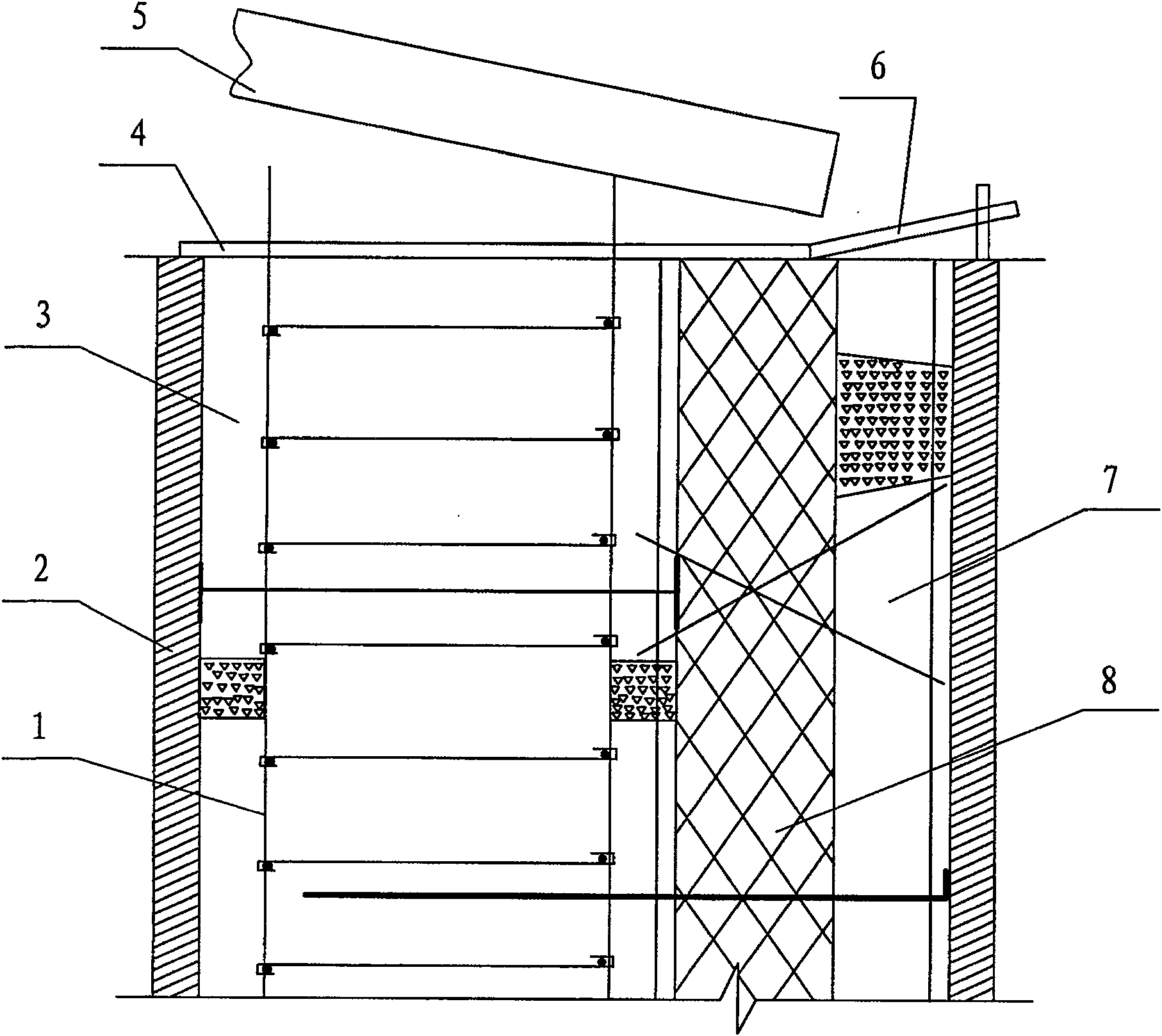

[0019] Example: see figure 1 , in the picture, 1-wall structure reinforcement, 2-formwork, 3-shear wall, 4-separation cover, 5-concrete pump pipe, 6-steel mesh, 7-protective wall, 8-polystyrene board .

[0020] The selective pouring method of aggregate particle size of thermal insulation wall concrete includes the following steps:

[0021] a. Prepare a concrete with separable aggregate particle size, wherein the aggregate particle size of the concrete is continuously mixed in sections, and the stones with a particle size of 5-10mm account for 30-35% of the total amount of stones, and the particle size is 10-30mm The stones accounted for 65-70% of the total amount of stones;

[0022] b. Use a set of concrete conveying equipment 5 to send the aggregate particle size separable concrete to the pouring work surface, and use the concrete aggregate particle size selection separation device to separate the concrete, so that the small particle size aggregate concrete enters the side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com