Preparation of coating superconductivity high W content Ni-W alloy baseband

An alloy-based, superconducting technology, applied in the direction of metal rolling, can solve the problems of difficult mass production, the inability to form a highly sharp cubic texture, and the inability to prepare Ni-W base tape, etc., to achieve high mechanical strength, cubic texture good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

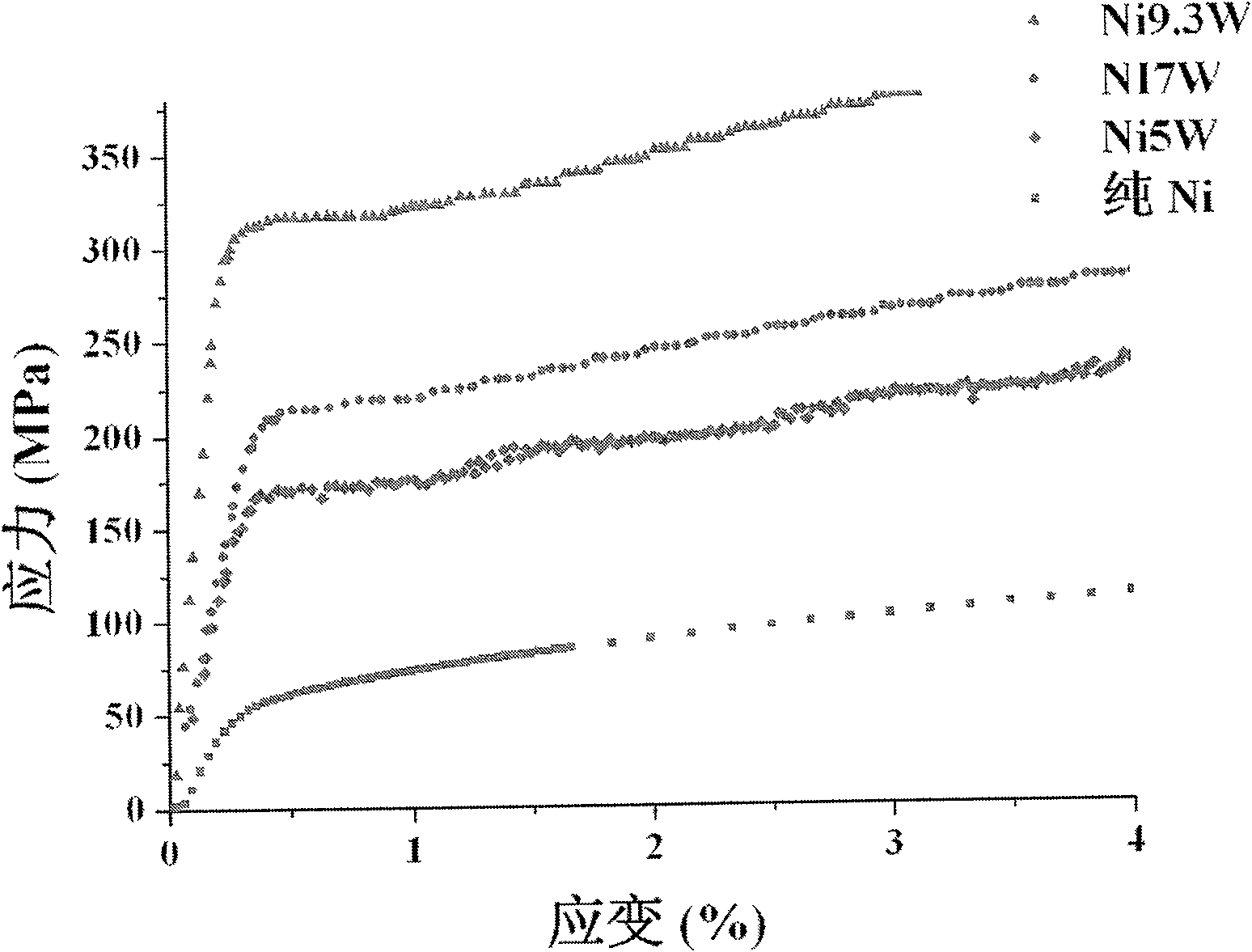

[0035] 1) Use Ni powder and W powder with a purity of 99.9% as raw materials, prepare the powder according to the atomic percentage of Ni and W at 93:7, use high-energy ball milling to mix evenly, the filling rate is CR=2, and the ball milling time is T m = 4h;

[0036] 2) Put the mixed powder into a mold for cold isostatic pressing at a pressure of 200MPa, keep for 8min, homogenize annealing at 900°C, and keep warm for 10h to obtain a Ni-W alloy billet;

[0037] 3) Warm rolling the alloy billet at a temperature of 250° C., using a pass deformation of 2 to 5%; when the total deformation is greater than 75%, stop warm rolling;

[0038]4) carry out pickling, remove surface oxide;

[0039] 5) Then start finish rolling at room temperature, adopt 2-5% pass deformation, use high-gloss rolls with surface roughness less than 10nm, the total deformation is greater than 98%, and the final thickness is 68 μm;

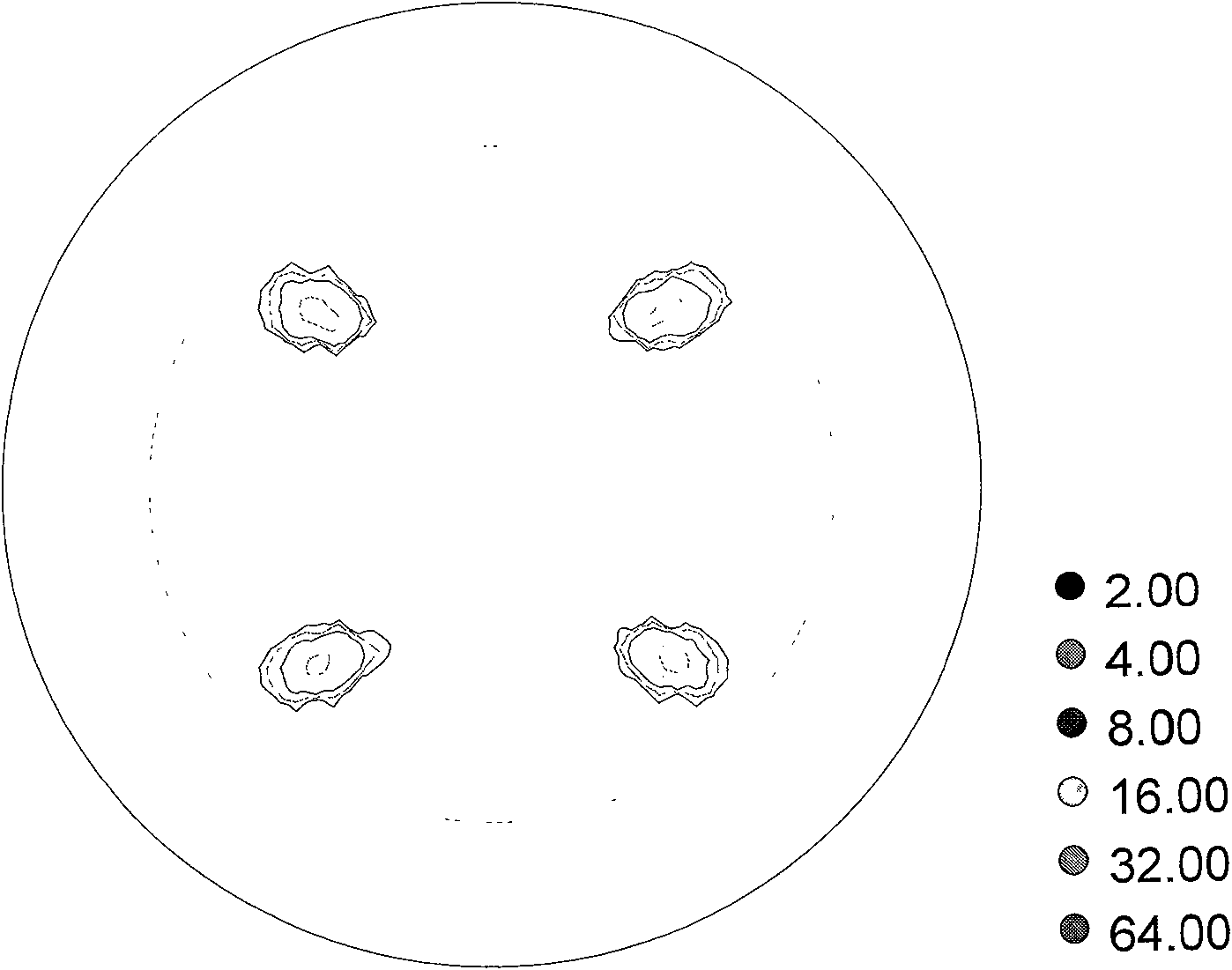

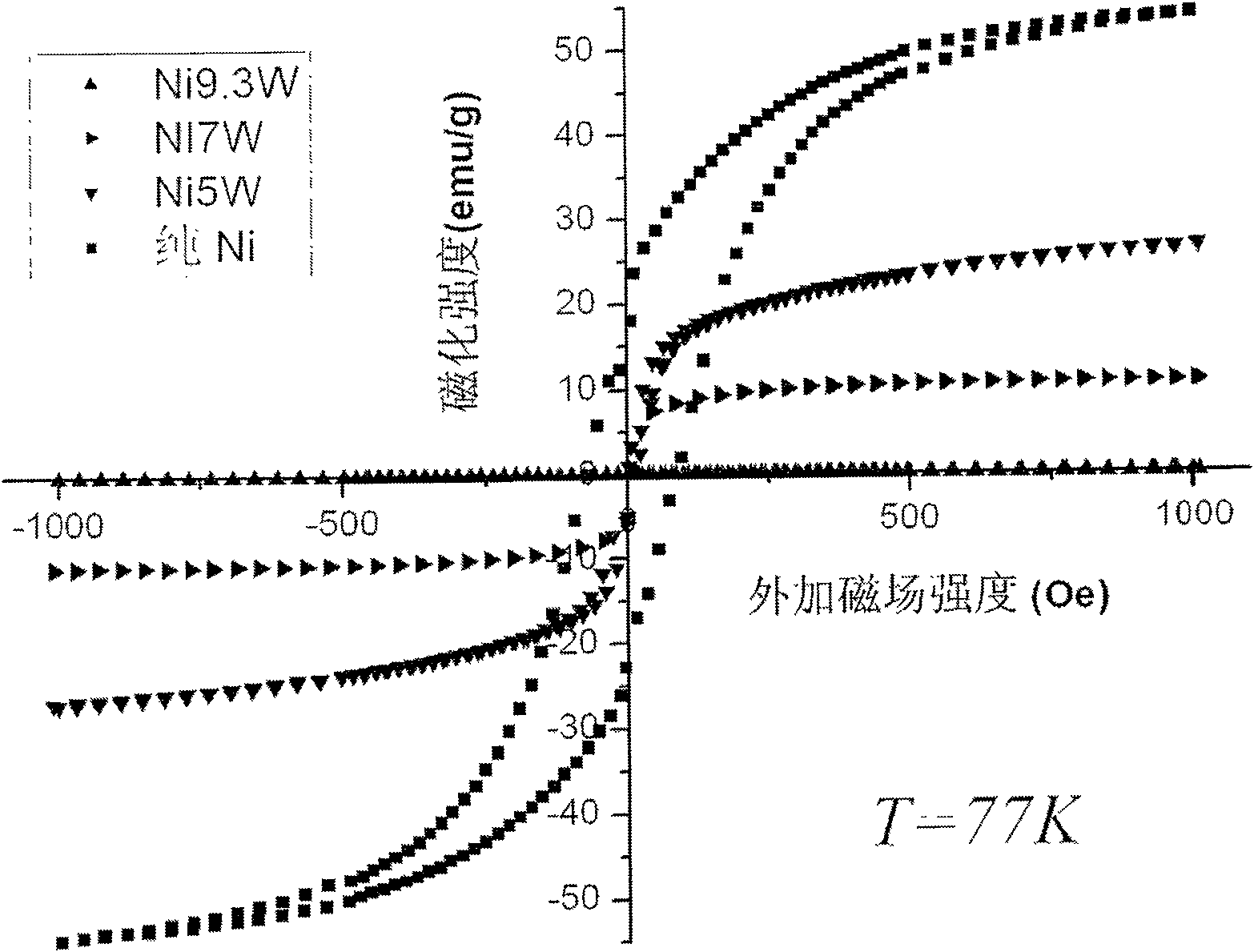

[0040] 6) For the strip obtained by rolling in Ar-4%H 2 Two-step recrystal...

Embodiment 2

[0043] 1) Ni powder and W powder are used as raw materials, the purity is 99.9%, the powder is prepared according to the atomic percentage of Ni and W at 93:7, and the powder is mixed evenly by high-energy ball milling, CR=10, T m = 1h;

[0044] 2) Put the mixed powder into a mold for cold isostatic pressing at a pressure of 250 MPa, keep it for 5 minutes, homogenize annealing at 1100°C, and keep it for 10 hours to obtain a Ni-W alloy billet;

[0045] 3) Warm rolling the alloy billet at a temperature of 250° C., using a pass deformation of 2 to 5%; when the total deformation is greater than 75%, stop warm rolling;

[0046] 4) carry out pickling, remove surface oxide;

[0047] 5) Then start finish rolling at room temperature, adopt 2-5% pass deformation, use high-gloss rolls with surface roughness less than 10nm, and the total deformation is greater than 98%;

[0048] 6) For the strip obtained by rolling in Ar-4%H 2 Carry out recrystallization annealing under protective atmo...

Embodiment 3

[0050] 1) Using Ni powder and W powder as raw materials, the purity is 99.9%, the powder is prepared according to the atomic percentage of Ni and W at 93:7, and the powder is mixed evenly by high-energy ball milling, CR=2, T m = 4h;

[0051] 2) Put the mixed powder into a mold for cold isostatic pressing at a pressure of 250 MPa and keep for 3 minutes; homogenize annealing at 1100°C and hold for 10 hours to obtain a Ni-W alloy billet;

[0052] 3) Carrying out warm rolling to the ingot at a temperature of 300°C, adopting a pass deformation of 2 to 5%; when the total deformation is greater than 75%, stop warm rolling;

[0053] 4) carry out pickling, remove surface oxide;

[0054] 5) Then start finish rolling at room temperature, adopt 2-5% pass deformation, use high-gloss rolls with surface roughness less than 10nm, and the total deformation is greater than 98%;

[0055] 6) For the strip obtained by rolling in Ar-4%H 2 Perform recrystallization annealing under protective atmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com