A kind of nonmagnetic cemented carbide for instrument shaft and its preparation method

A cemented carbide, non-magnetic technology, applied in the field of non-magnetic cemented carbide for instrument shafts and its preparation, can solve the problems of limited use range, low hardness, measurement accuracy interference, etc., and achieve a wide range of use and high hardness. , the effect of good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

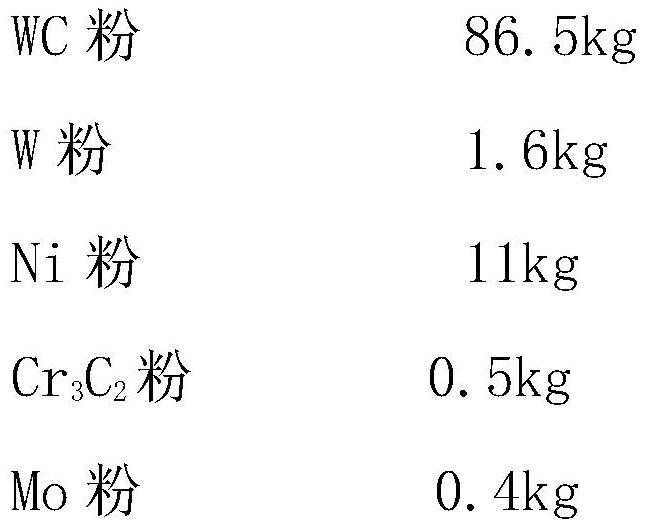

[0038] This embodiment takes the total weight of 100kg as an example for illustration:

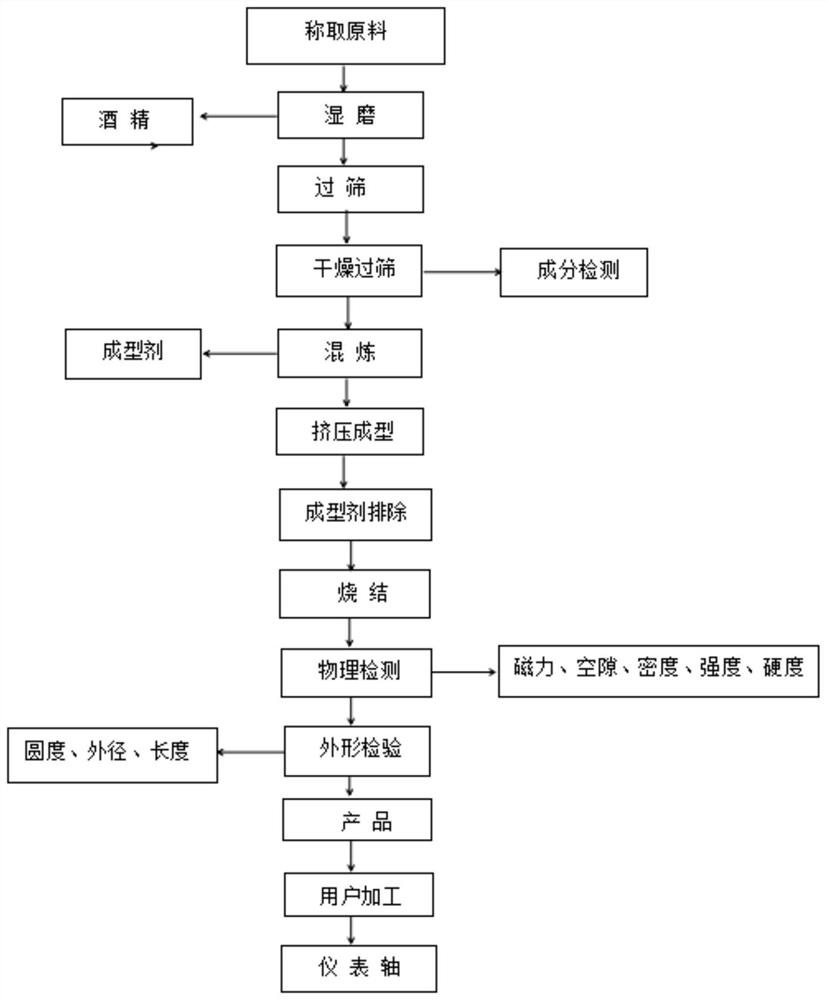

[0039] Step 1, weighing raw materials:

[0040]

[0041] WC powder requirements: Fsss particle size: 2-4u, carbon content: 5.91-5.95%;

[0042] W powder requirements: Fsss particle size: 2-4u;

[0043] Ni powder requirements: Fsss particle size: 1.5-2.5u, Ni powder is preferably Canadian nickel powder;

[0044] Cr 3 C 2 Powder requirements: Fsss particle size: 1-2u;

[0045] Mo powder requirements: Fsss particle size: 1-2u;

[0046] Step 2, mixing the above raw materials, and then adding a wet grinding agent for wet grinding (such as alcohol);

[0047] Step 3, sieving;

[0048] Step 4, after drying, sieve again;

[0049] Step 5, adding a molding agent for mixing;

[0050] Step 6, extrusion molding;

[0051] Step 7, get rid of forming agent;

[0052] Step 8, sintering;

[0053] Step 9, physical testing; check whether the magnetic force, void, density, strength, and hardness o...

Embodiment 2

[0062] This embodiment is basically the same as Embodiment 1, except that MoC powder is used instead of Mo powder.

Embodiment 3

[0064] The present embodiment is basically the same as embodiment 1, and the difference is that the raw materials taken are:

[0065]

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com