Method for reducing carbon nanotube loss when sealing and joining field emission display device

A technology of carbon nanotubes and display devices, which is applied in the manufacture of discharge tubes/lamps, electrical components, ships or lead wires, etc. It can solve the problems of uneven cathode emission, affecting the service life of devices, and short service life. Achieve the effects of reducing carbon nanotube loss, improving emission uniformity, and reducing blowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

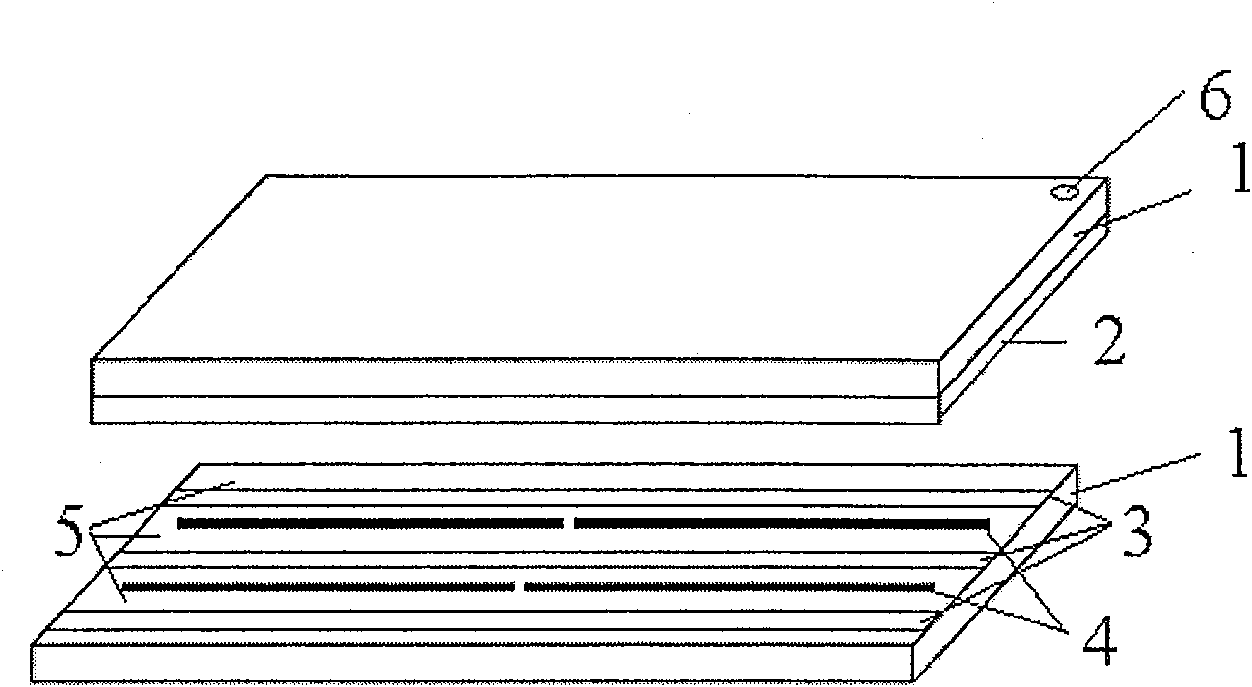

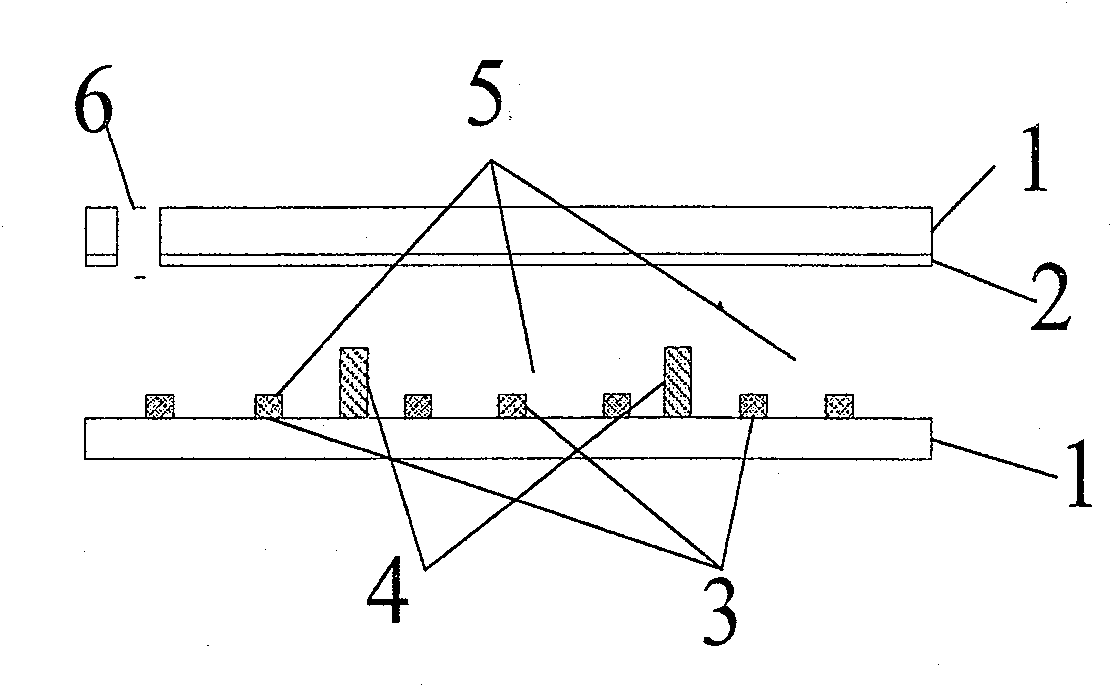

[0011] The method that reduces carbon nanotube field emission display device (CNT-FEDs) of the present invention and carbon nanotube is lost in sealing process is applied in the field emission display of 5 inches, in carbon nanotube field emission display device (CNT-FEDs ) During the sealing process, an insulating dielectric strip 4 with a length of 8-12 centimeters, a width of 0.2-0.5 millimeters and a thickness of 40-80 microns made by screen printing is printed between two adjacent cathodes 3, The vacuum sealing cavity is evenly divided into 3-20 small vacuum cavities 5 with an insulating dielectric strip 4, and the insulating dielectric strip 4 is made of SiO 1 (CH 2 CH 3 ) 2 Materials are printed. The small vacuum chambers 5 communicate with each other by leaving a gap of 0.6-1.2 centimeters between the two ends and the middle of the insulating dielectric strip 4, as the exhaust channels of each chamber, forming a new type of carbon nanotube field emission display dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com