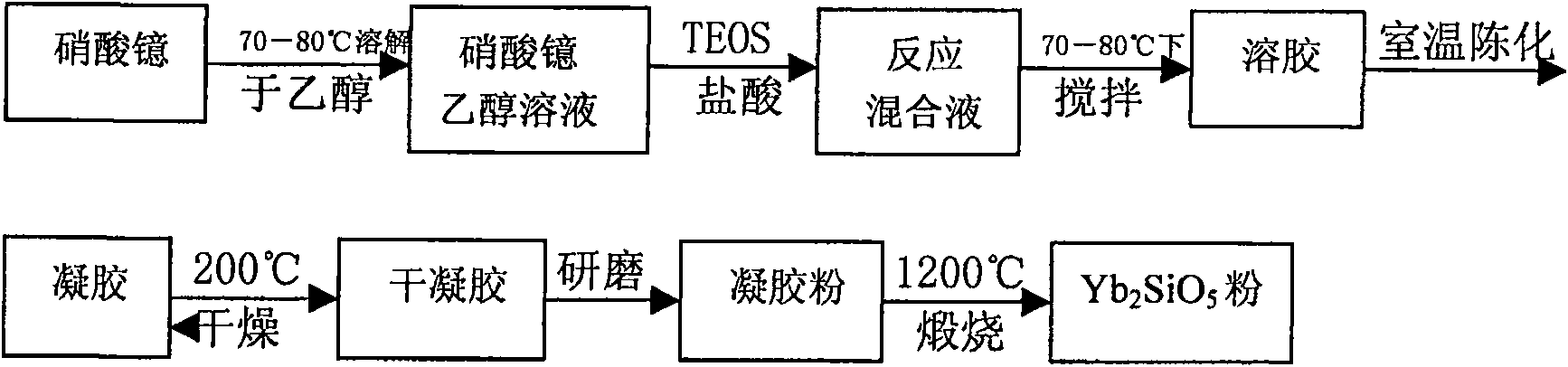

Sol-gel process for preparing Yb2SiO5 powder

A sol-gel and powder technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., to achieve the effect of good repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) 70.06g ytterbium nitrate Y b (NO 3 ) 3 ·nH 2 O (n=6~7) was dissolved in 70.03g ethanol under the condition of 70℃ water bath, then the temperature of the solution was lowered to room temperature, the solution concentration was 1.70mol / L, TEOS:H 2 O:C 2 h 5 OH=1:12:20;

[0023] (2) At room temperature, add 15.62g TEOS into the ethanol solution of ytterbium nitrate, stir to make it evenly mixed;

[0024] (3) 0.5 ml of hydrochloric acid as a catalyst is added dropwise in the above-mentioned solution under stirring to obtain a reaction mixture;

[0025] (4) Stir the above reaction mixture vigorously for 12 hours under the condition of a water bath at 70° C. to obtain a transparent sol;

[0026] (5) Aging the sol for 24 hours at room temperature to obtain a gel;

[0027] (6) Dry the wet gel in an oven at 200°C for 8 hours to obtain a dry gel, and grind it into a fine powder in a mortar;

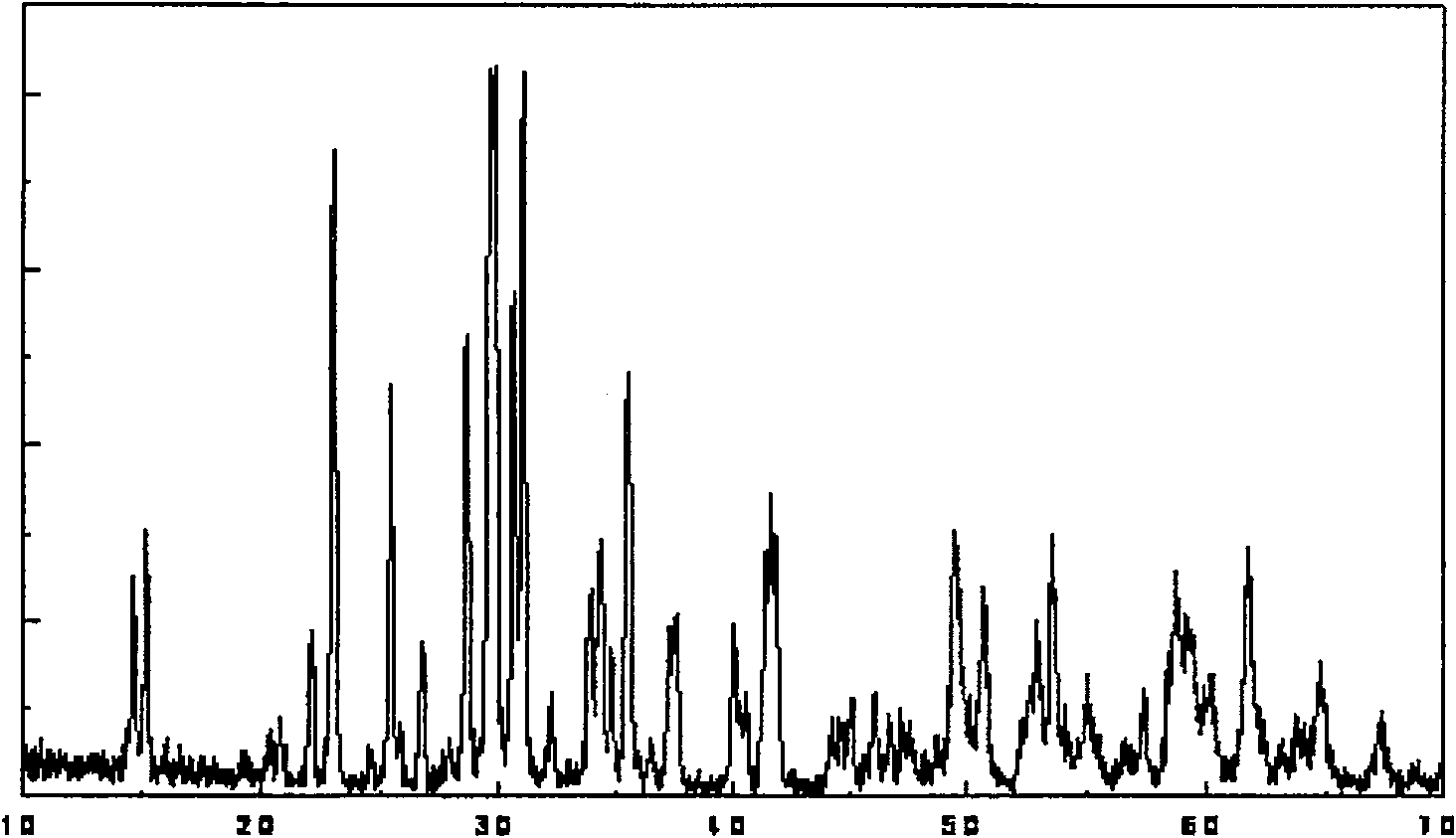

[0028] (7) Calcining the xerogel powder at 1200°C for 1 hour to obtain Yb ...

Embodiment 2

[0030] (1) 35.03g ytterbium nitrate Y b (NO 3 ) 3 ·nH 2 O (n=6~7) was dissolved in 12.42g ethanol under the condition of 80 ℃ water bath, then the temperature of the solution was lowered to room temperature, the solution concentration was 4.77mol / L, TEOS:H 2 O:C 2 h 5 OH=1:12:7;

[0031] (2) At room temperature, add 7.8g TEOS into the ethanol solution of ytterbium nitrate, stir to make it evenly mixed;

[0032] (3) 0.25ml of hydrochloric acid as a catalyst is added dropwise in the above solution under stirring to obtain a reaction mixture;

[0033] (4) Vigorously stir the above reaction mixture for 10 min in a water bath at 70°C to obtain a transparent sol;

[0034] (5) aging the sol at room temperature for 16 hours to obtain a gel;

[0035] (6) Dry the wet gel in an oven at 200°C for 8 hours to obtain a dry gel, and grind it into a fine powder in a mortar;

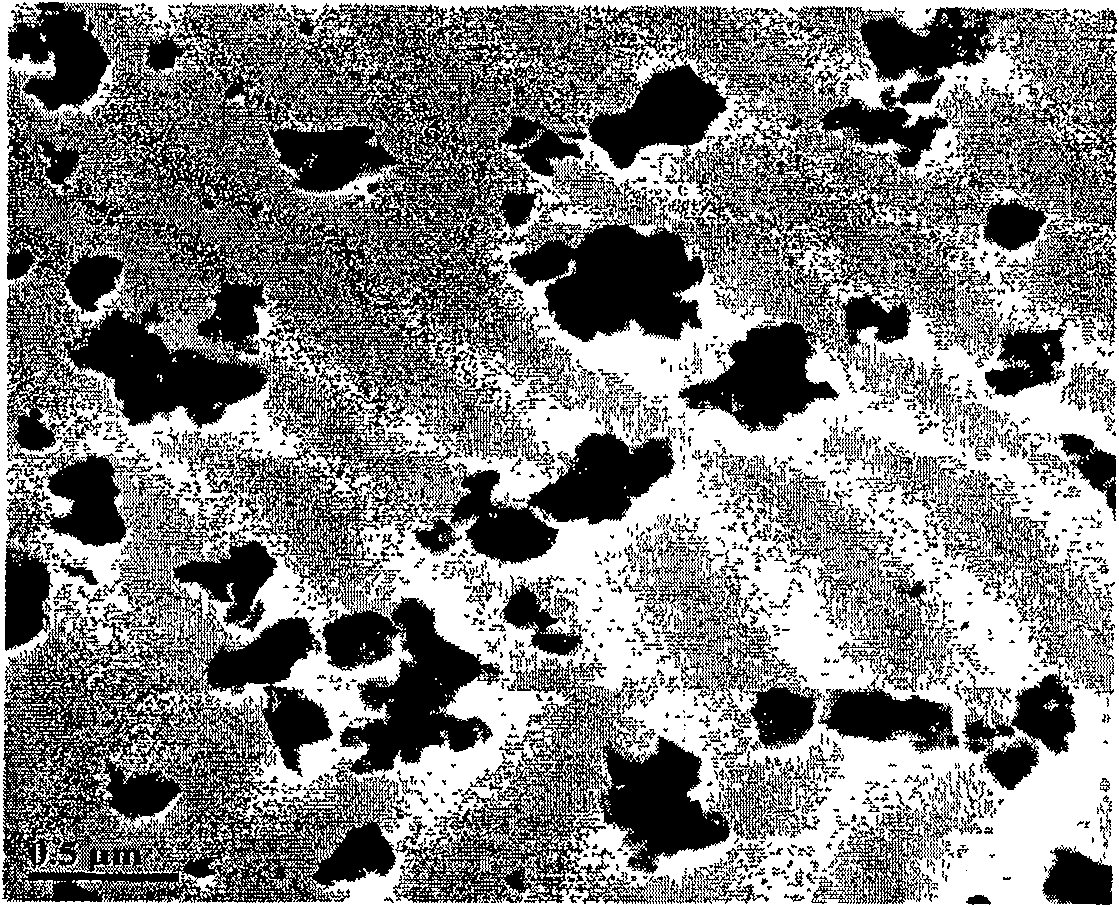

[0036] (7) Calcining the xerogel powder at 1200°C for 1 hour to obtain Yb with a particle size of about 1 μm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com