Power device in electronic optical path system of electronic bundle impact furnace

A technology of electron beam bombardment and optical path system, which is applied in the direction of electric heating devices, electric furnaces, furnaces, etc., can solve problems such as failure to meet the requirements of smelting process, random fluctuation of accelerating voltage, and electron beam off-target, etc., and achieve fast dynamic follow-up performance indicators and easy adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

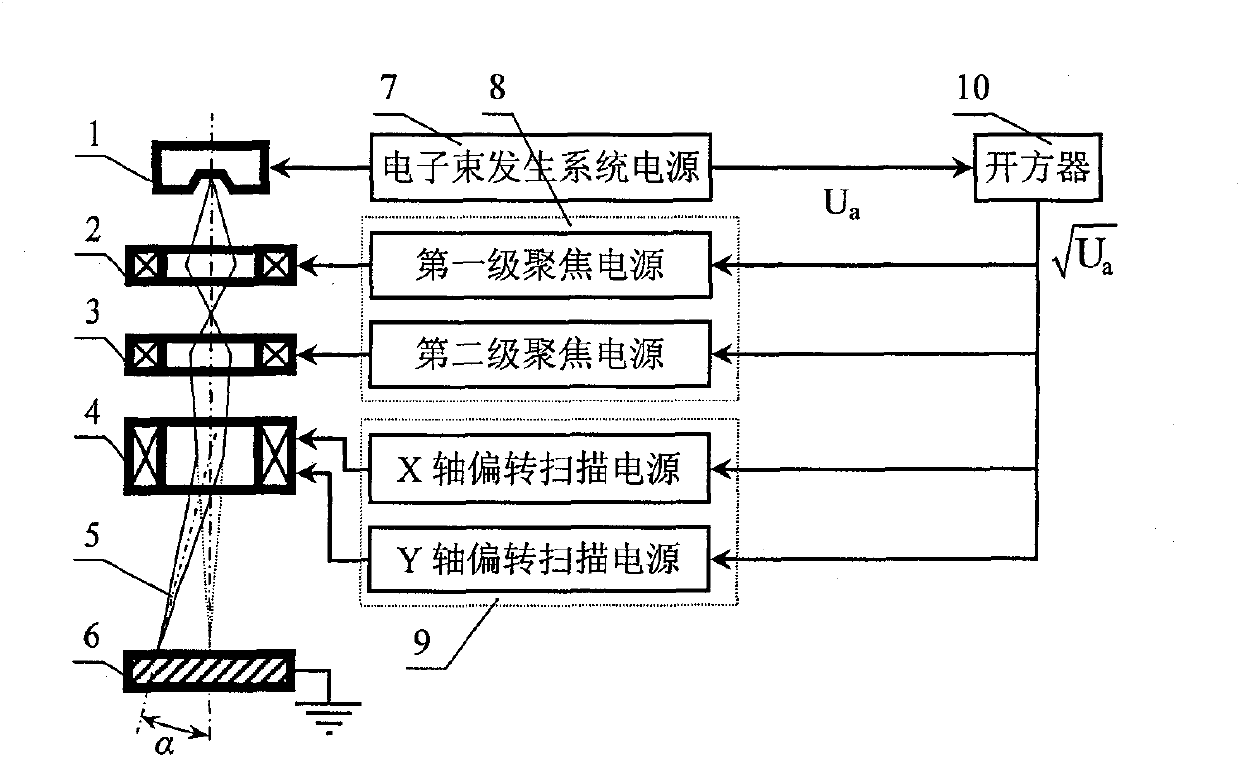

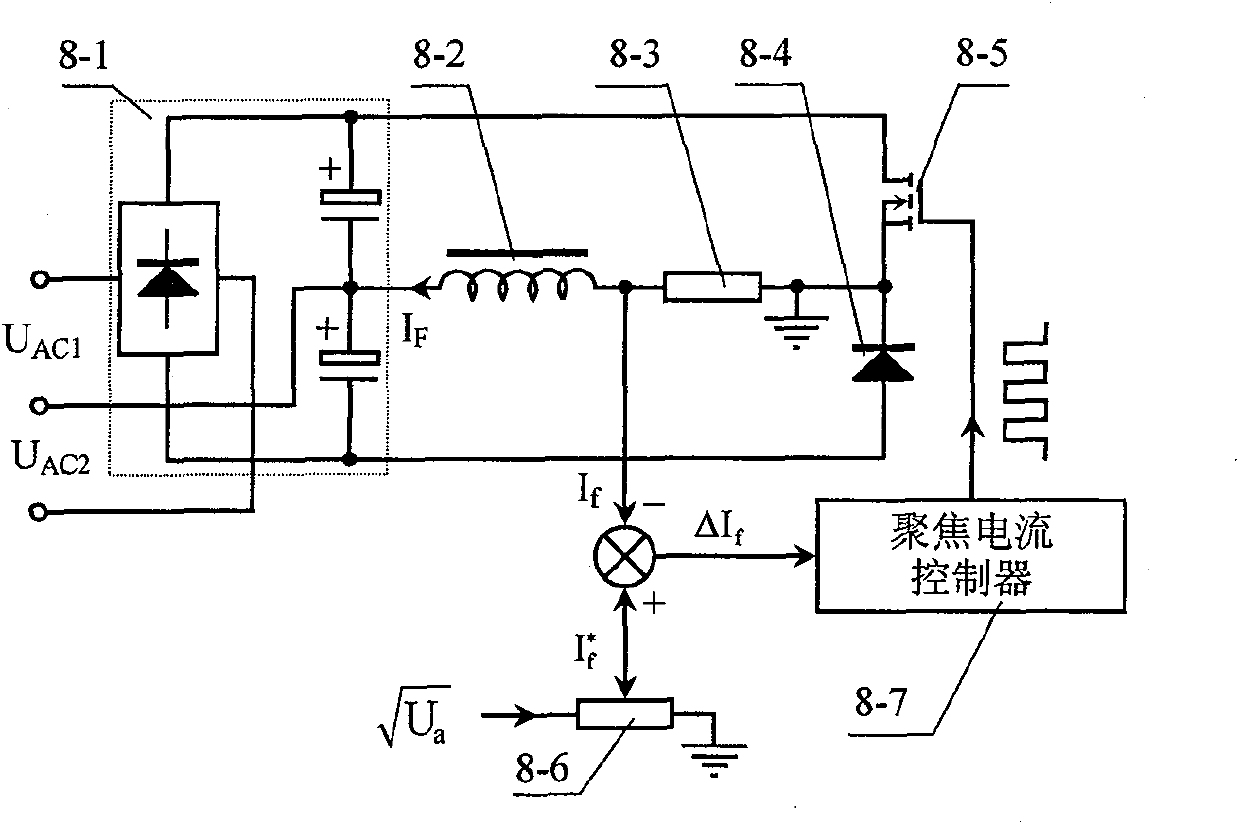

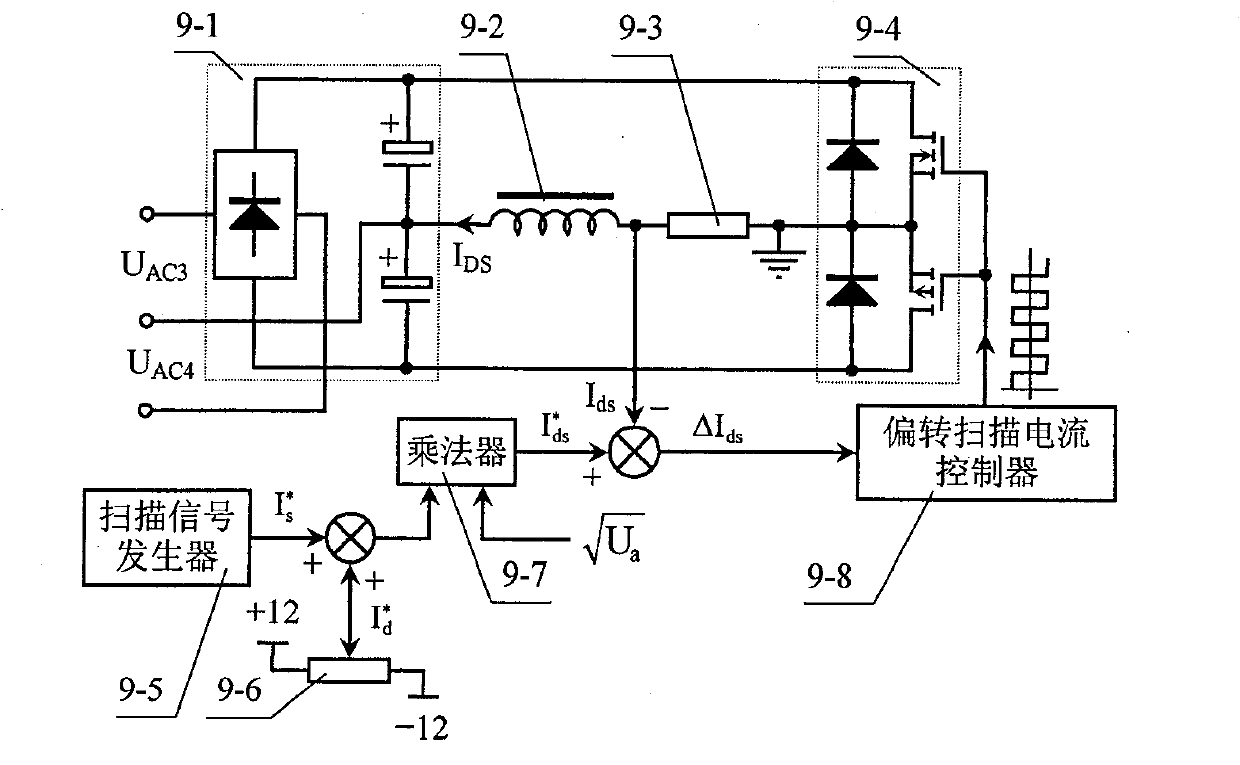

[0021] Example of the power supply device for the electron beam system of the electron beam bombardment furnace of the present invention figure 1 As shown, the electron beam generated by the electron beam generating system 1 is focused and deflected and scanned by the electron optical system of the electron beam bombardment furnace, and then the electron beam is reasonably distributed on the target 6 for heating and melting. The electron beam optical system has a first focusing coil 2 and a second focusing coil 3 as a focusing magnetic lens, and a deflection scanning coil 4 . The structure of the focus power supply 8 of the two focus coils 2, 3 is the same as the control law of the focus current. The deflection scan coil 4 has two pairs of coils with magnetic poles, which are symmetrically installed in the electron gun. The magnetic field of one pair of magnetic poles deflects the electron beam along the X-axis of the radial plane, and the magnetic field of the other pair of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com