Garbage combustion furnace for producing gas and its usage method

A garbage combustion and gas technology, applied in biofuels, coking ovens, household furnaces/stoves, etc., can solve the problems of gas output rate, high cost, complex structure and other problems in the polluted environment, and achieve no smoke, low cost, and good benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

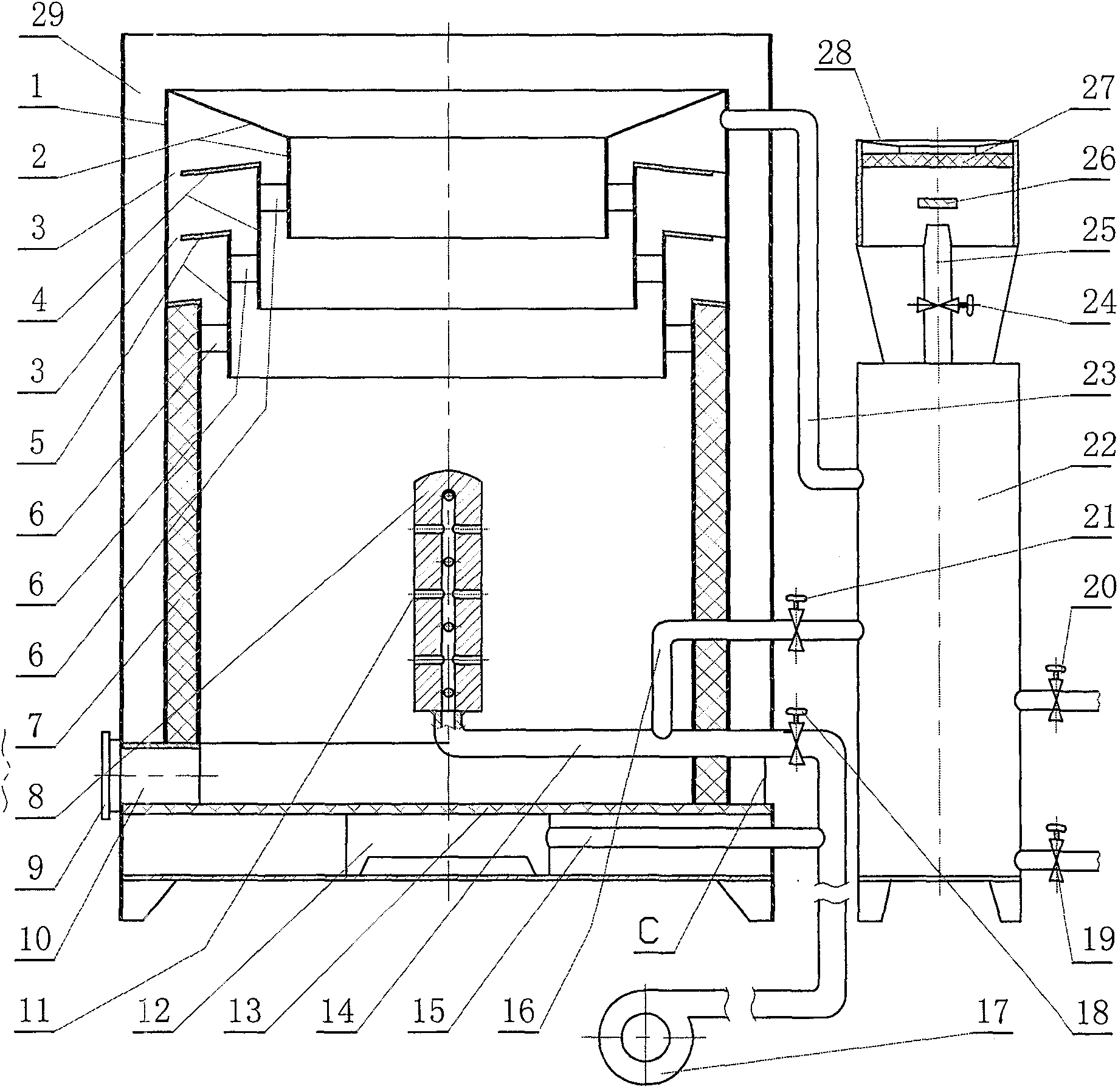

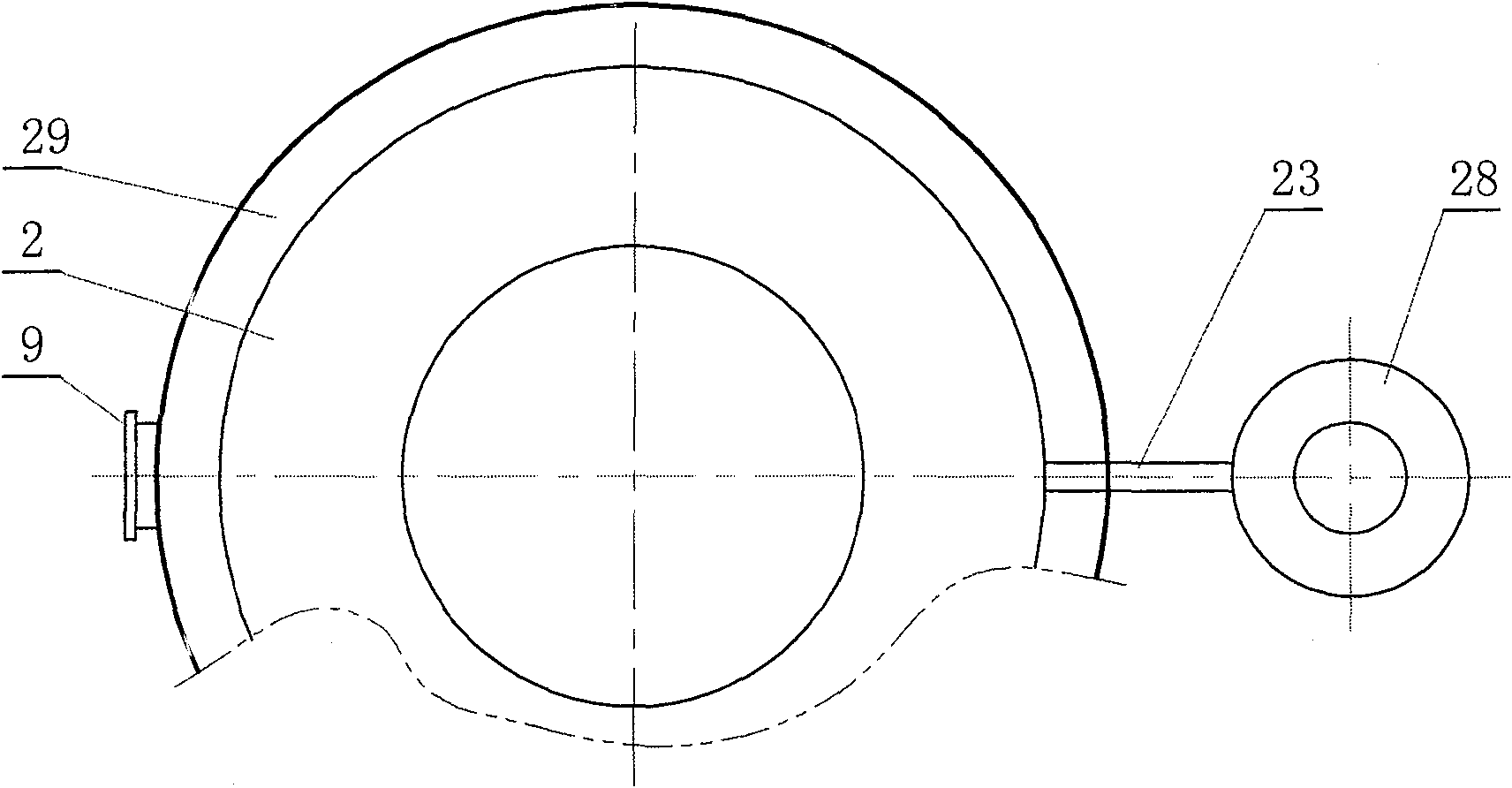

[0020] Example 1 as Figure 1-2 Shown: a garbage burning furnace for producing gas, the cylindrical inner gas collecting hood 2, the cylindrical middle gas collecting hood 4 and the cylindrical outer gas collecting hood 5 are respectively discontinuously welded to the upper part of the furnace shell 1, and the inner The periphery of the gas collecting hood 2, the central gas collecting hood 4 and the outer gas collecting hood 5 are respectively welded with the furnace shell 1 to have evenly distributed transparent arc gaps 3; The sleeve is inserted into the upper part of the middle gas collection hood 4, and the inner gas collection hood 2 and the middle gas collection hood 4 are discontinuously welded on the evenly distributed support piece 6; 4 sets of the middle gas collection hood with a diameter smaller than the large gas collection hood 5 are inserted into the large gas collection On the top of the cover 5, the middle gas-collecting hood 4 and the large gas-collecting ho...

Embodiment 2

[0024] Example 2 as Figure 1-2 Shown: a kind of use method of the garbage incineration furnace of producing gas described in embodiment 1, comprises the following steps:

[0025] [1] When using for the first time, all kinds of organic wastes are filled into the furnace from the top of the furnace shell 1, and the circumferential drying interlayer 29 on the periphery of the furnace shell 1 is filled simultaneously.

[0026] [2] Open the main gas delivery valve 18, intake valve 21, exhaust valve 20, drain valve 19, electric furnace 12 and blower 17; 11. The electric furnace 12 enters the furnace to support combustion; the air entering the hollow air storage tank 22 through the intake pipe 16 discharges the waste gas and residual water in the hollow air storage tank 22 .

[0027] [3] After the electric furnace 12 burns the metal fire grate 13 and ignites the organic waste in the furnace, close the electric furnace 12, the intake valve 21, the exhaust valve 20 and the drain valv...

Embodiment 3

[0031] Embodiment 3: The hollow gas storage tank 22 and the furnace shell 1 described in Embodiment 1 can be installed in a room isolated from each other, and the gas output pipe 25 can be connected to a commercially available gas stove through a gas hose, especially for large-scale Garbage incinerators that produce more gas are more suitable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com