Waste wire stripping machine

A stripping machine and wire technology, applied in the direction of electronic waste recycling, recycling technology, electrical components, etc., can solve the problems of environmental pollution, insufficient utilization of renewable resource plastics, etc., and achieve the effect of comprehensive utilization of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

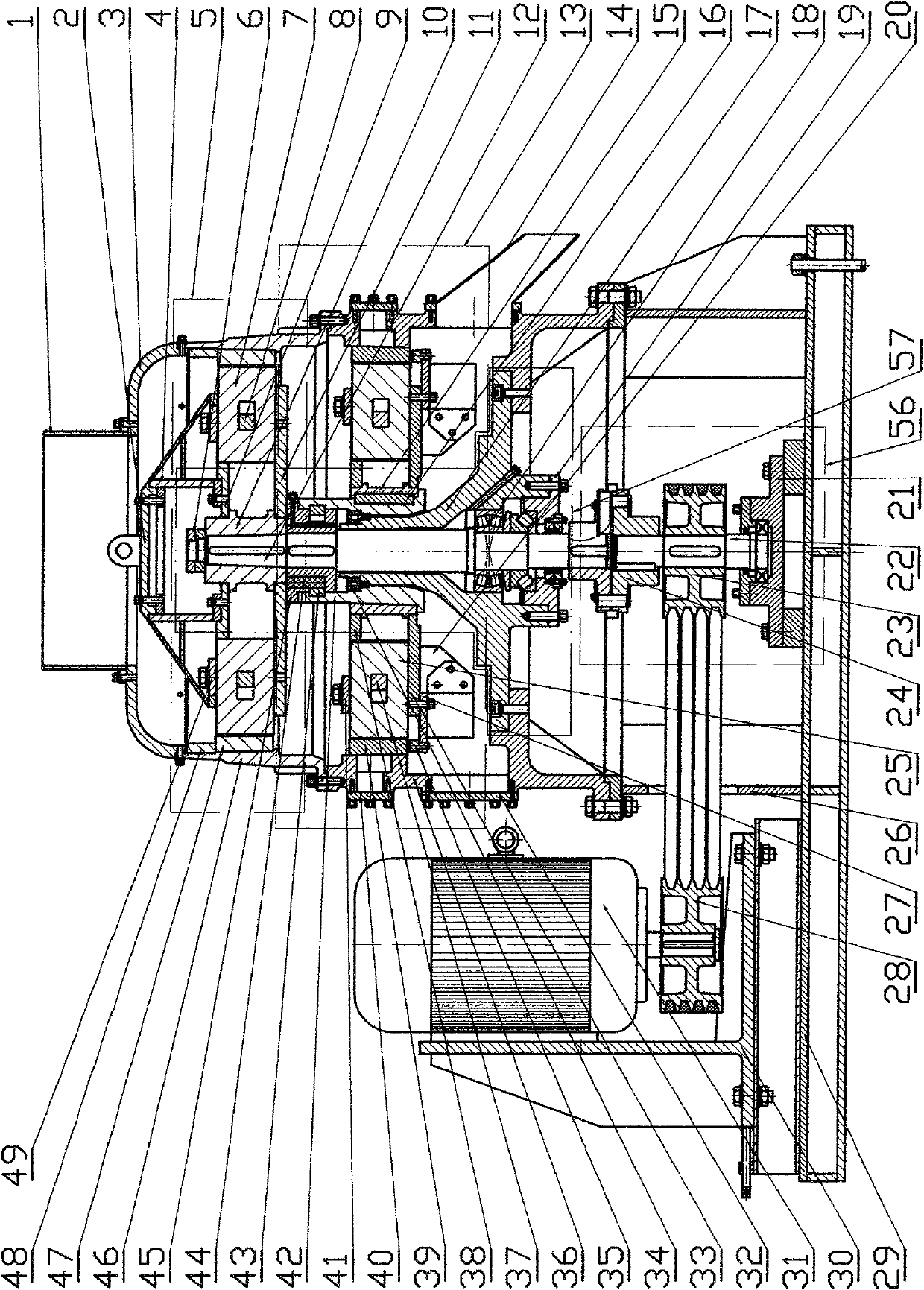

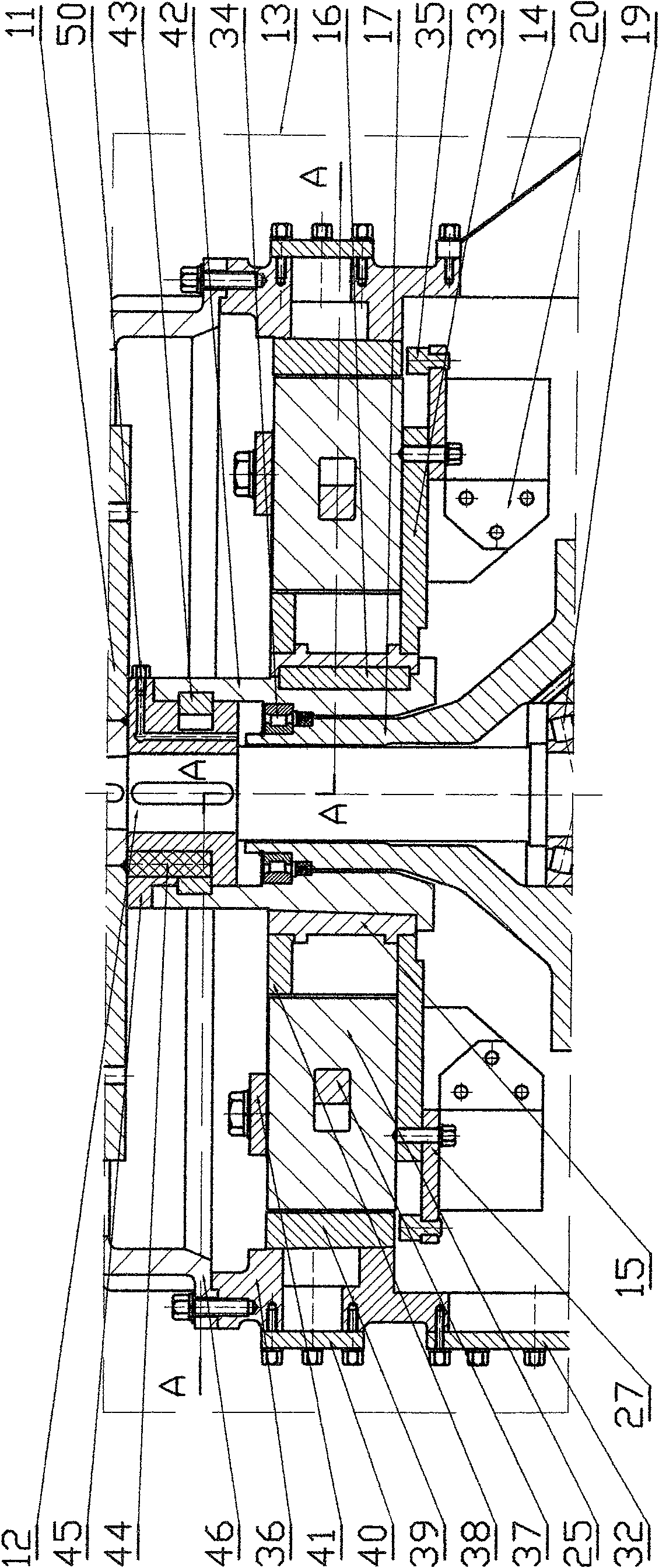

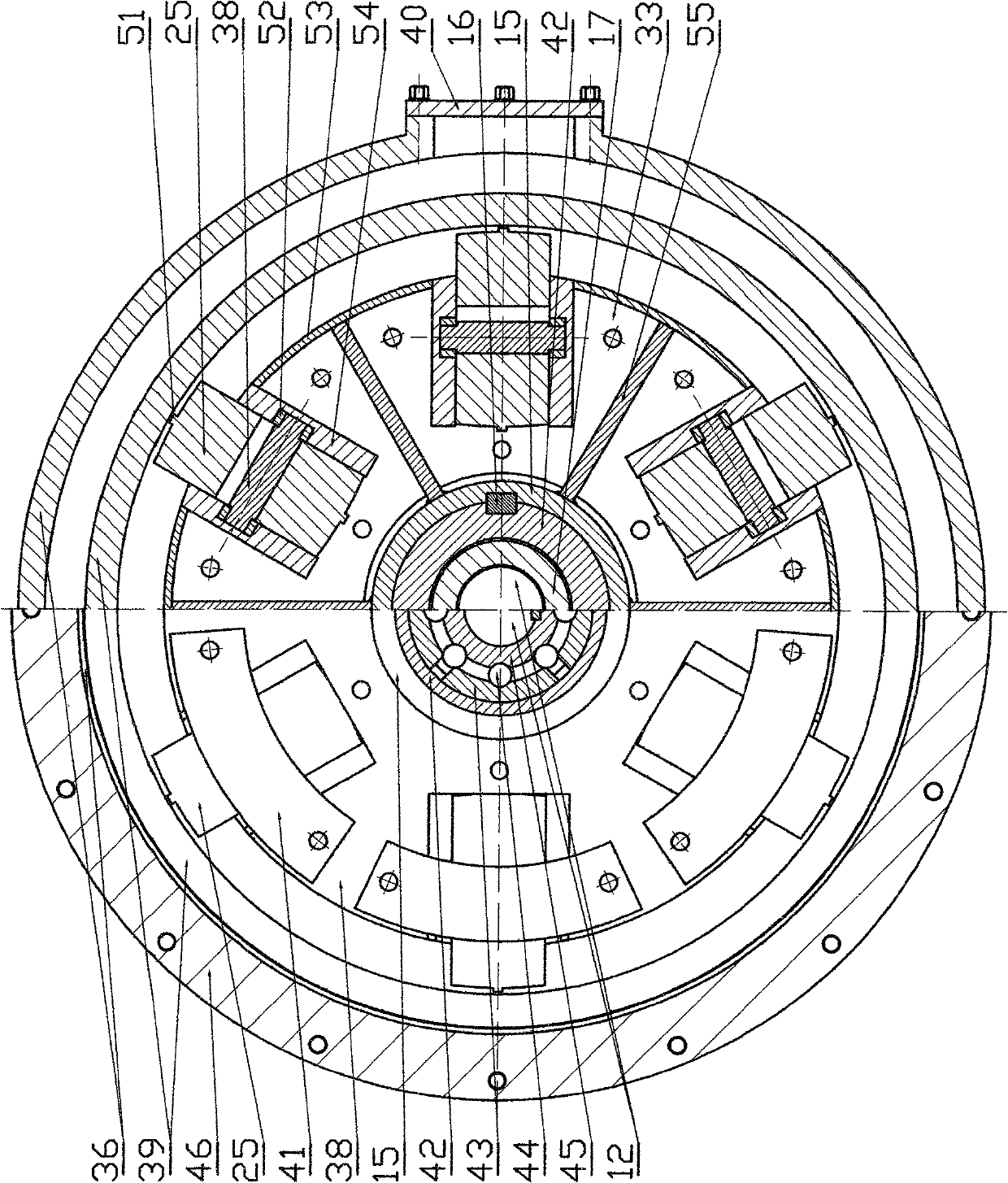

[0020] The present invention consists of a machine base 29, a power transmission device 56, an inlet hopper 1, an outlet hopper 14, a casing, an upper cover 2, a first-stage oblique triangular helical tooth surface stripping device 5, a secondary rounded helical tooth surface stripping device 13 and a main shaft Device 57 constitutes.

[0021] The casing is composed of casing top 3, casing upper part 46, casing middle part 36 and casing bottom 26; 26 is installed on the machine base 29, and the power transmission device 56 is installed therein; the middle part 36 of the casing is divided into three parts, and its lower part is a cavity, and the lower end of the middle part protrudes inward, forming a step for installing the main shaft device 57 The middle and upper end of the middle part is a cavity, the outer side is equipped with a discharge hopper 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com