New technology of valve sealing element vacuum induction pile-up welding hard alloy and improved equipment

A cemented carbide, valve sealing technology, applied in metal processing equipment, welding equipment, metal processing and other directions, to achieve the effect of improving productivity, optimizing surfacing process, improving quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

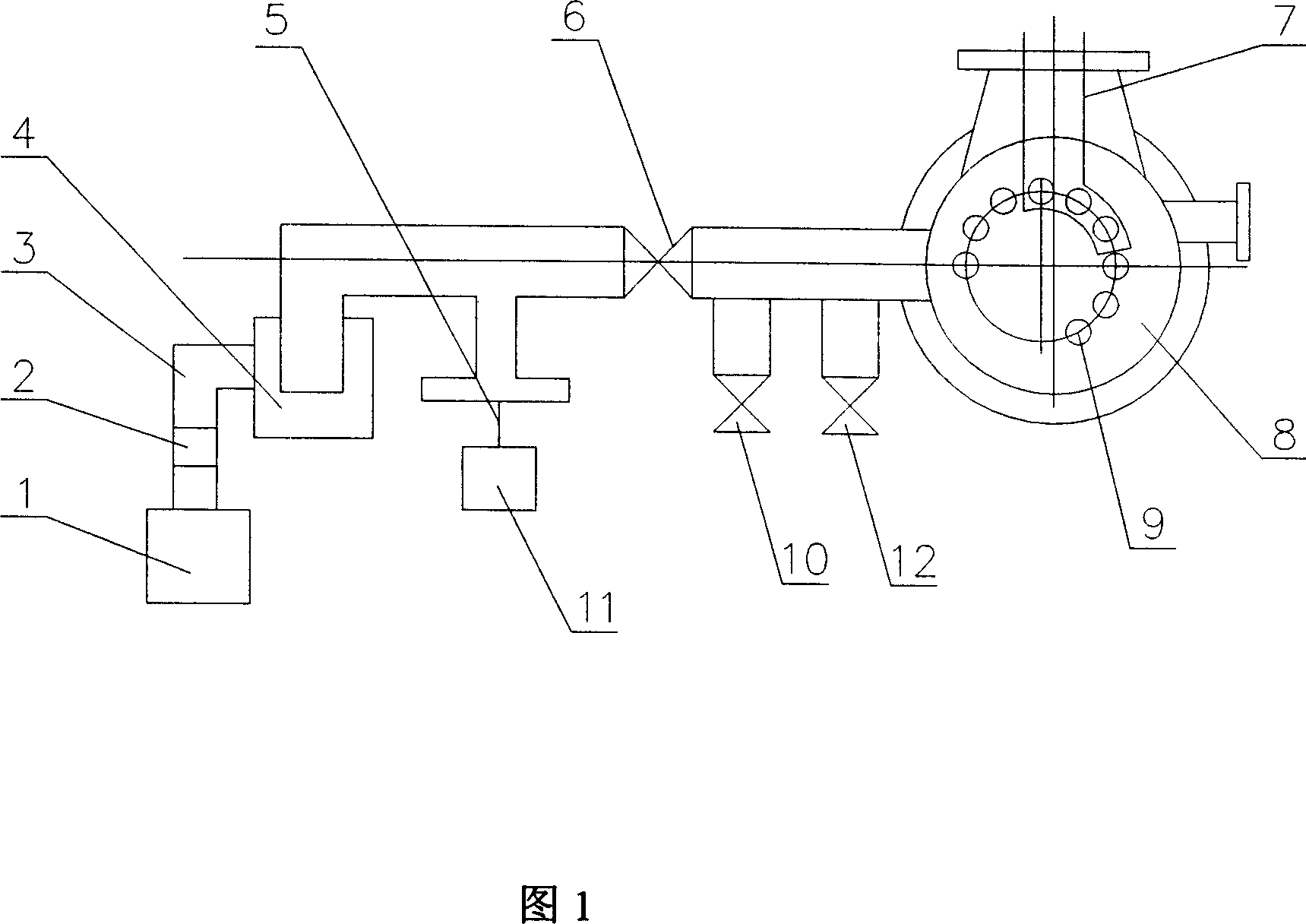

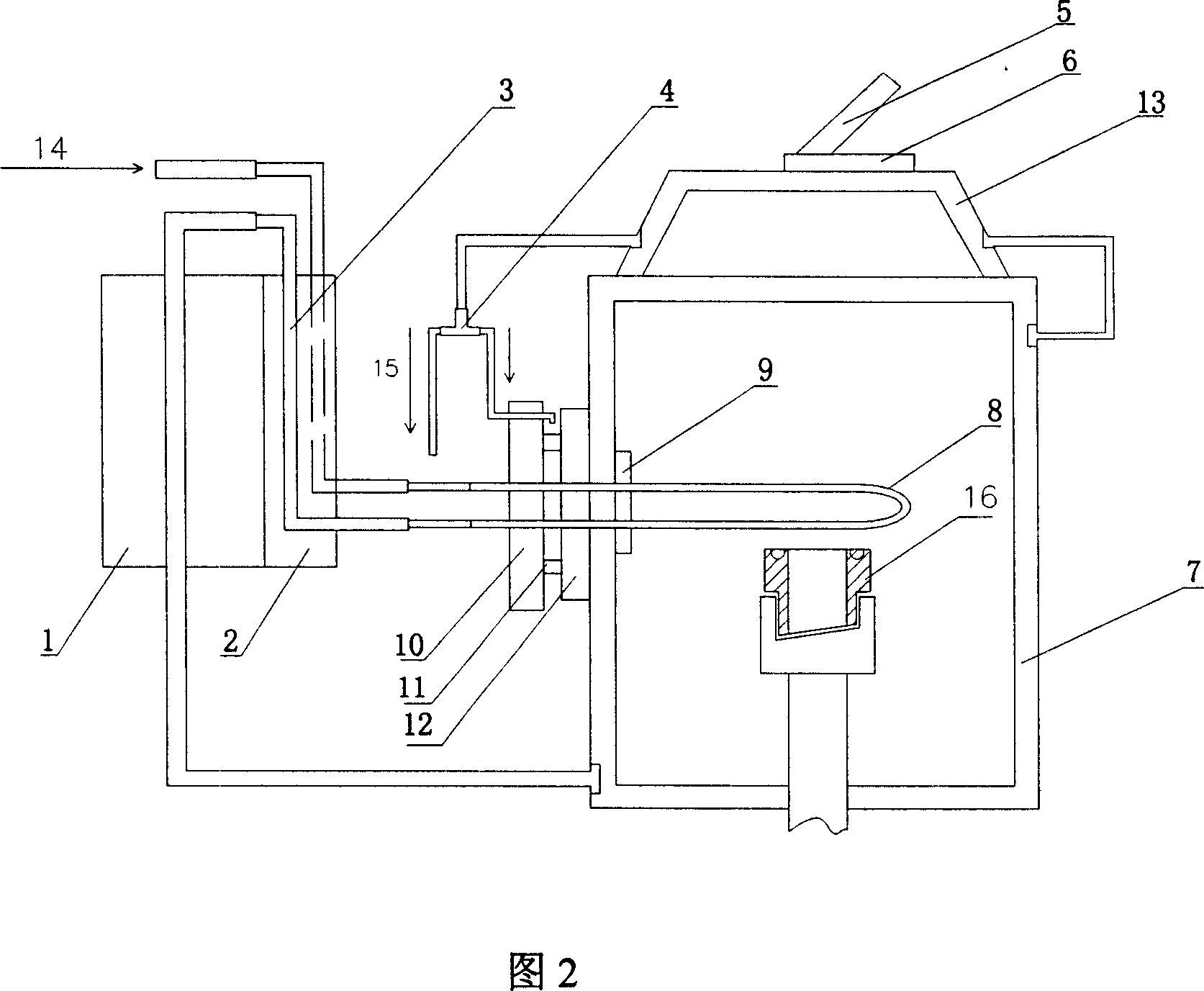

Method used

Image

Examples

Embodiment 1

[0017] The improved vacuum high-frequency induction surfacing equipment is connected to the GP60 high-frequency machine, and the 3 / 4" (nominal diameter 20mm) valve seat process example is surfacing.

[0018] Seat material is 1Cr13. Its main chemical composition (mass fraction, %) is 0.10C, 1.00Mn, 1.00Si, 0.035P, 0.030S, 11.7Cr. The depth of the U-shaped groove on the pre-surfacing sealing surface is 2.0mm to 2.2mm, and the wall thickness of the U-shaped groove is 0.8mm to 1.0mm. 15 surfacing welds per furnace each time. Select 200 mesh (0.126mm) Stellite158D powder as the surfacing flux. The chemical composition (mass fraction, %) of the surfacing flux is 0.50C, 22.7Cr, 2.4Fe, 0.01Mn, 0.01Mo, 2.2Ni, 1.7Si, 4.6W, Yu Co. Using 3 / 4" tire hand wipe pressure molding, after drying and then high-frequency sintering surfacing welding, the vacuum degree in the surfacing process is 10 -1 Pa~10 -2 Pa, grid current 0.51A, anode current 1.6A, anode voltage 11KV, tank circuit voltage ...

Embodiment 2

[0020] The improved vacuum high-frequency induction surfacing equipment is connected to the GP60 high-frequency machine, and the surfacing welding process example of a valve seat with a full diameter of 2″ (outer diameter ¢58mm) is used.

[0021] The valve seat material is 1Cr13, and its main chemical composition (mass fraction, %) is 0.10C, 1.00Mn, 1.00Si, 0.035P, 0.030S, 11.7Cr. The depth of the U-shaped groove on the pre-surfacing sealing surface is 2.0mm to 2.1mm, the wall thickness of the U-shaped groove is 1.0mm to 1.10mm, and the amount of surfacing welding in each furnace is 6. 200 mesh (0.126mm) Co-L powder is selected as the surfacing flux. The chemical composition (mass fraction, %) of the surfacing flux is 0.70C, 0.95Si, 0.61B, 29.50Cr, 4.00W, 2.69Fe, and Co. It is molded by hand wiping and pressing with a full-diameter 2″ tire. After drying, it is then subjected to high-frequency sintering and surfacing welding. The vacuum degree during the surfacing process is 10...

Embodiment 3

[0023] Connect the improved vacuum high-frequency induction surfacing equipment to the GP60 high-frequency machine, and surfacing a 1 1 / 4 ″ (nominal diameter 32mm) valve seat process example.

[0024]Seat material is 1Cr13. Its main chemical composition (mass fraction, %) is 0.10C, 1.00Mn, 1.00Si, 0.035P, 0.030S, 11.7Cr. The depth of the U-shaped groove on the pre-surfacing sealing surface is 2.0mm-2.2mm, and the wall thickness of the U-shaped groove is 0.9mm-1.10mm. 12 surfacing welds per furnace each time. Select 200 mesh (0.126mm) Stellite158D powder as the surfacing flux. The chemical composition (mass fraction, %) of the surfacing flux is 0.50C, 22.7Cr, 2.4Fe, 0.01Mn, 0.01Mo, 2.2Ni, 1.7Si, 4.6W, Yu Co. The 1 1 / 4″ mold is hand wiped and pressed, dried and then subjected to high-frequency sintering and surfacing welding. The vacuum degree during the surfacing process is 10 -1 Pa~10 -2 Pa, grid current 0.54A, anode current 1.7A, anode voltage 11.2KV, tank circuit voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com