Instant coffee

A coffee, soluble technology, applied in the field of coffee packaging, can solve the problems of sugar addition, addition, unacceptable to consumers, etc., to achieve the effect of improving quality and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

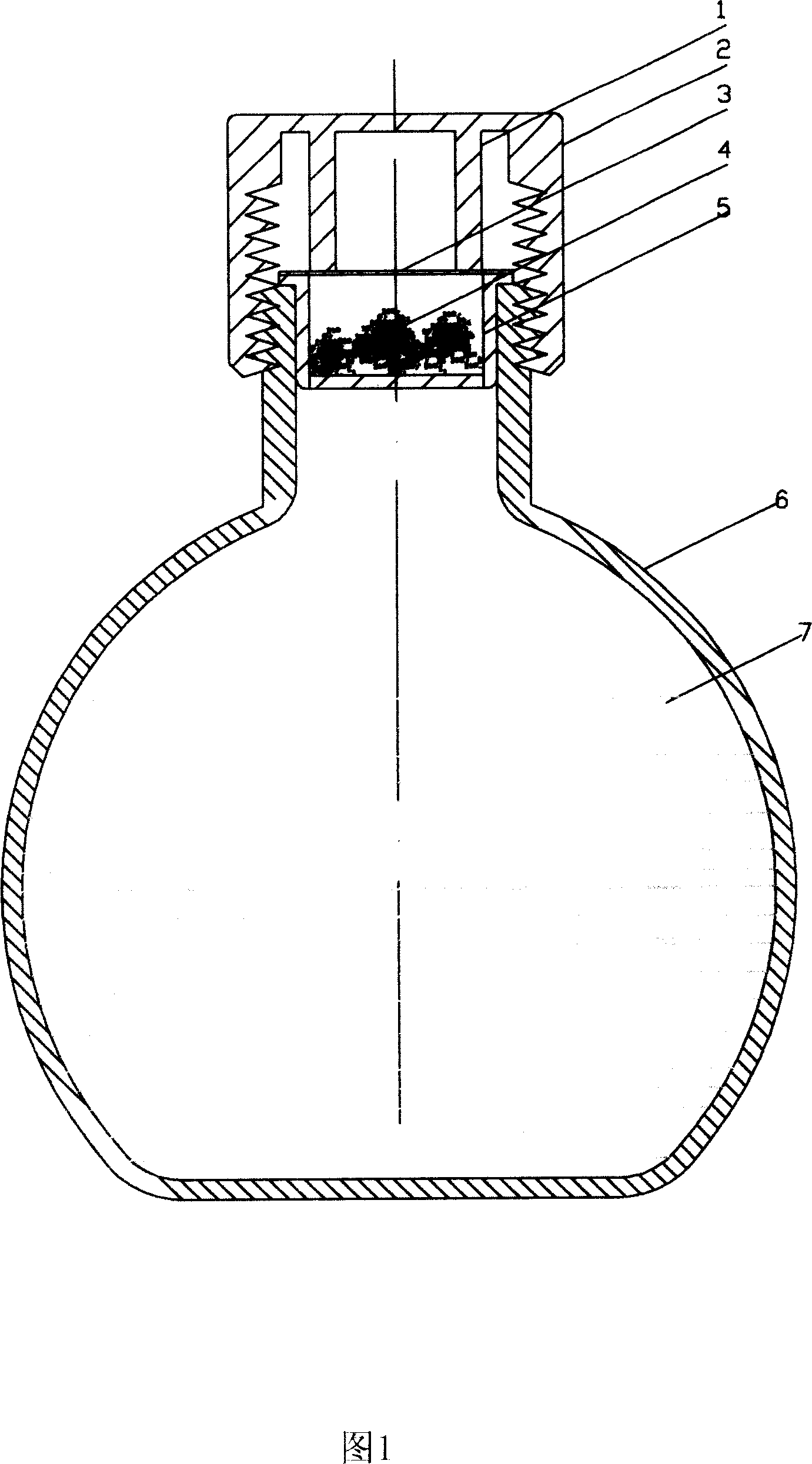

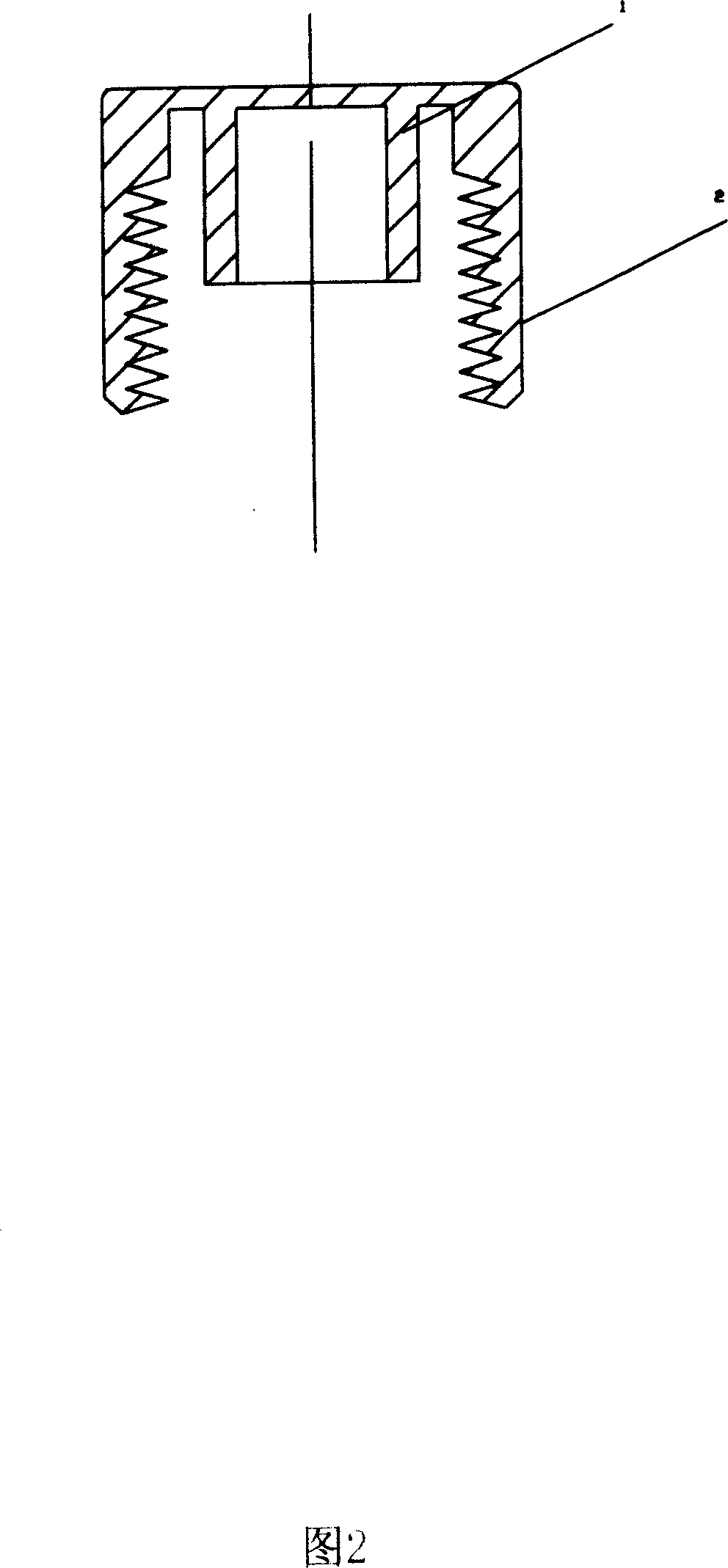

[0018] A certain amount of coffee granule powder (4) is filled in the crystallization chamber (5) in conjunction with accompanying drawing 1, and the crystallization chamber (5) has a sealing film (3), and the coffee granule powder (4) is filled in the crystallization chamber (5) The inner sealing film (3) is sealed. If the sealing film (3) is made of pure polymer material, it is sealed by heat pressing. If the sealing film (3) is made of aluminum-plastic composite material, it is sealed by high-frequency induction. After the sealing film (3) is sealed, it is set in the One end of the bottle mouth of the liquid chamber (6), then the bottle cap (2) is covered, and the bottle cap (2) is screwed in to the bottom of the bottle. There is a structural part (1) in the bottle cap (2) along with the bottle cap (2). The bottom of the bottle is screwed in. When the bottle cap (2) is screwed into the bottom of the bottle for a certain length, there is a structural part (1) inside the bottl...

Embodiment 2

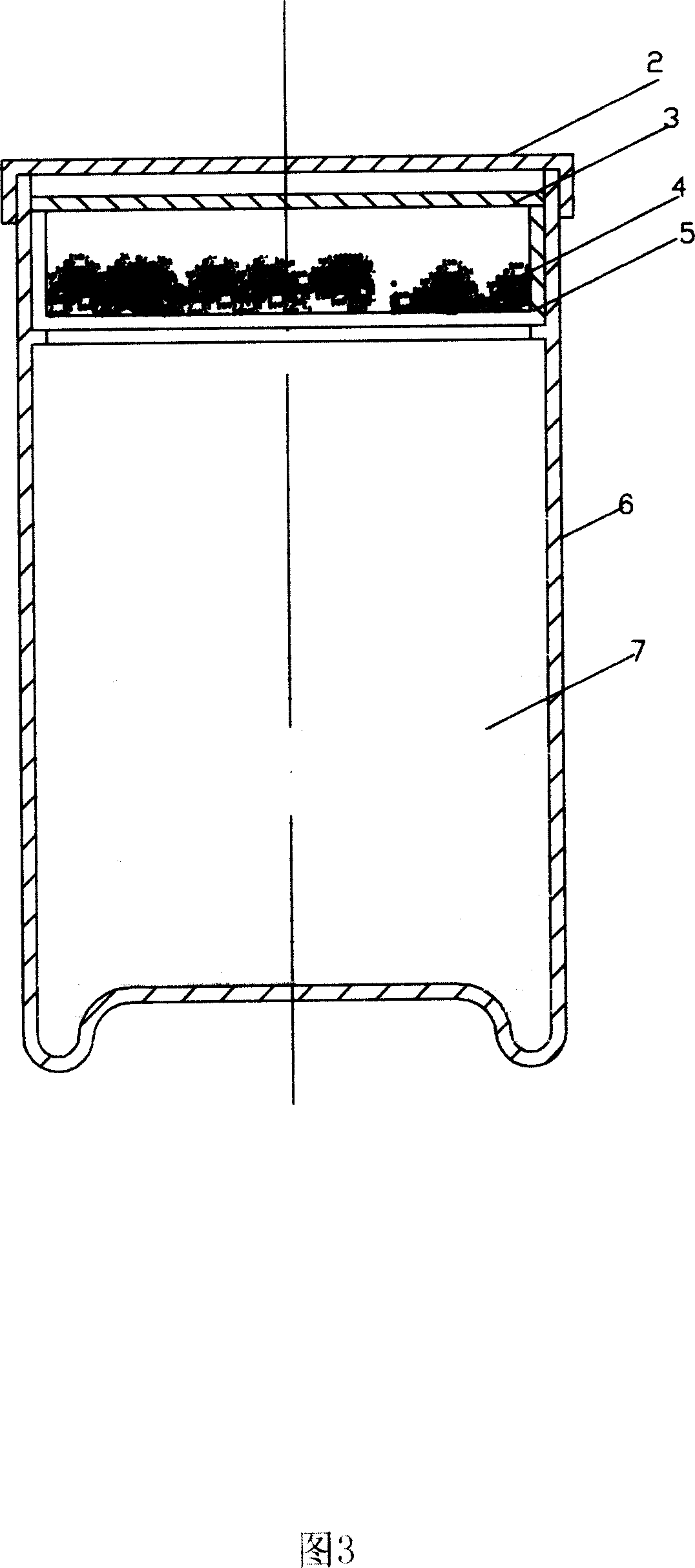

[0020] A certain amount of coffee granule powder (4) is filled in the crystallization chamber (5) in conjunction with accompanying drawing 3, and the crystallization chamber (5) has a sealing film (3), and the coffee granule powder (4) is filled in the crystallization chamber (5) The inner sealing film (3) is sealed. If the sealing film (3) is made of pure polymer material, it is sealed by heat pressing. If the sealing film (3) is made of aluminum-plastic composite material, it is sealed by high-frequency induction. After the sealing film (3) is sealed, it is set in the One end of the bottle mouth of the liquid chamber (6), then the bottle cap (2) is covered, and the bottle cap (2) is removed so that the sealing film (3) of the crystallization chamber (5) is exposed, and the crystallization chamber (5) is covered with a drinking straw. ) of the sealing film (3) and the bottom of the crystallization chamber (5) are punctured, and after the bottom of the crystallization chamber (...

Embodiment 3

[0022] A certain amount of coffee granule powder (4) is filled in the crystallization chamber (5) in conjunction with accompanying drawing 3 and accompanying drawing 4, and the crystallization chamber (5) has a sealing film (3), and the coffee granule powder (4) is filled in the crystallization chamber (5). The sealing film (3) in the chamber (5) is sealed. If the sealing film (3) is made of pure polymer material, it is sealed by heat pressing. If the sealing film (3) is made of aluminum-plastic composite material, it is sealed by high-frequency induction. The sealing film (3) After sealing, it is set on one end of the bottle mouth of the liquid chamber (6), and then the bottle cap (2) is covered, and the bottle cap (2) is removed so that the sealing film (3) of the crystallization chamber (5) is exposed to the liquid chamber (6). The radial pressure of the bottle mouth of the liquid chamber (6) is deformed in the circumferential direction of the bottle mouth of the liquid cham...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap