Self-holding underwater section buoy of using multiple sources of energy, and drive method

A composite energy, self-sustaining technology, used in buoys, motor vehicles, boat salvage and other directions, can solve the problems of high cost, low battery power density, and failure of the injection pump, and achieves improved work performance, improved fuel utilization, and solved the The effect of restricted working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

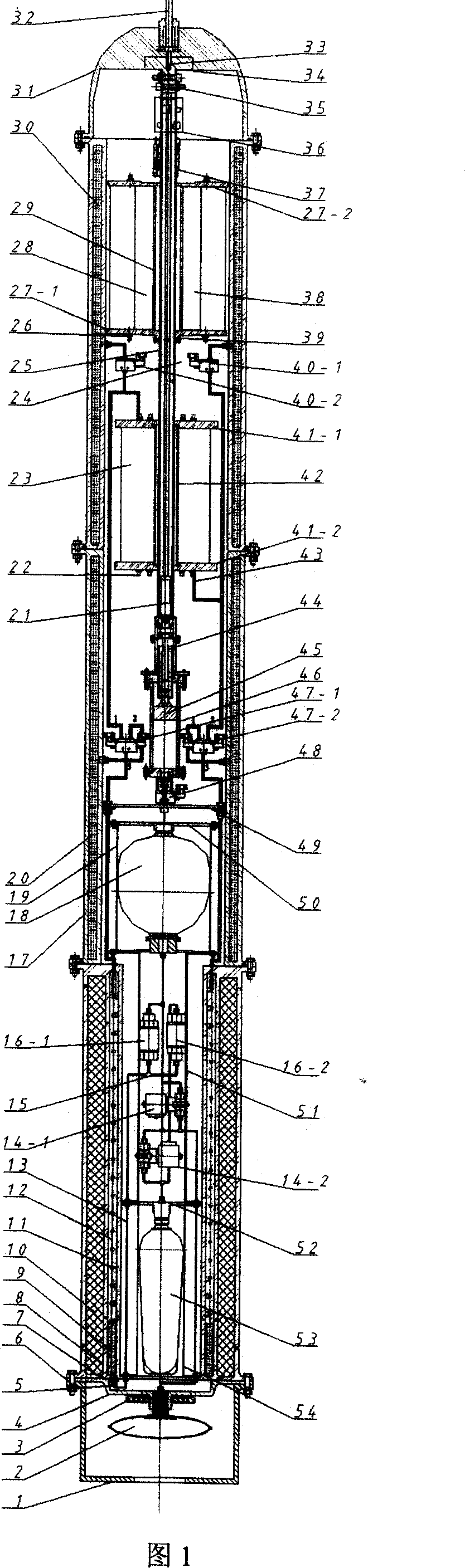

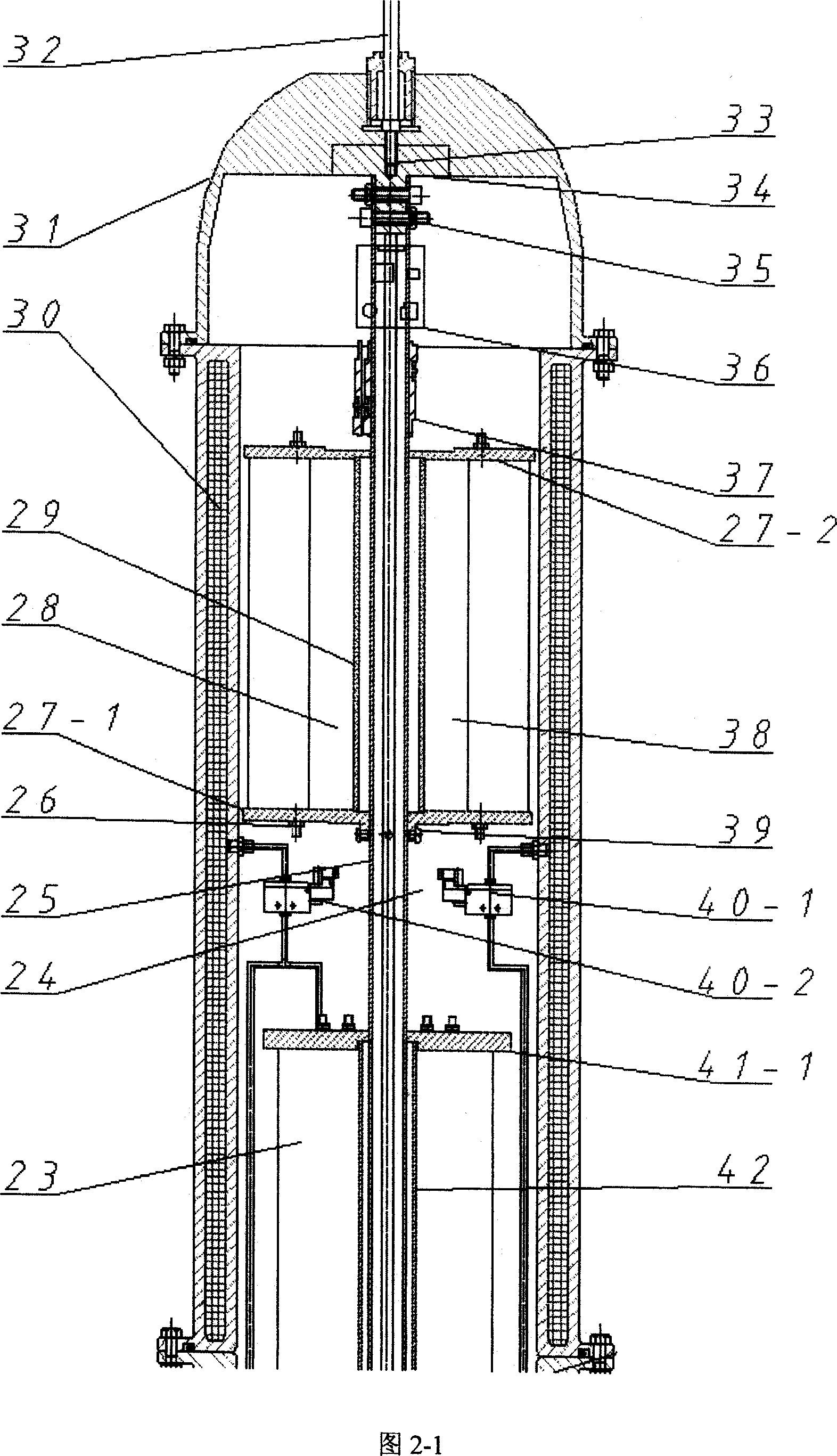

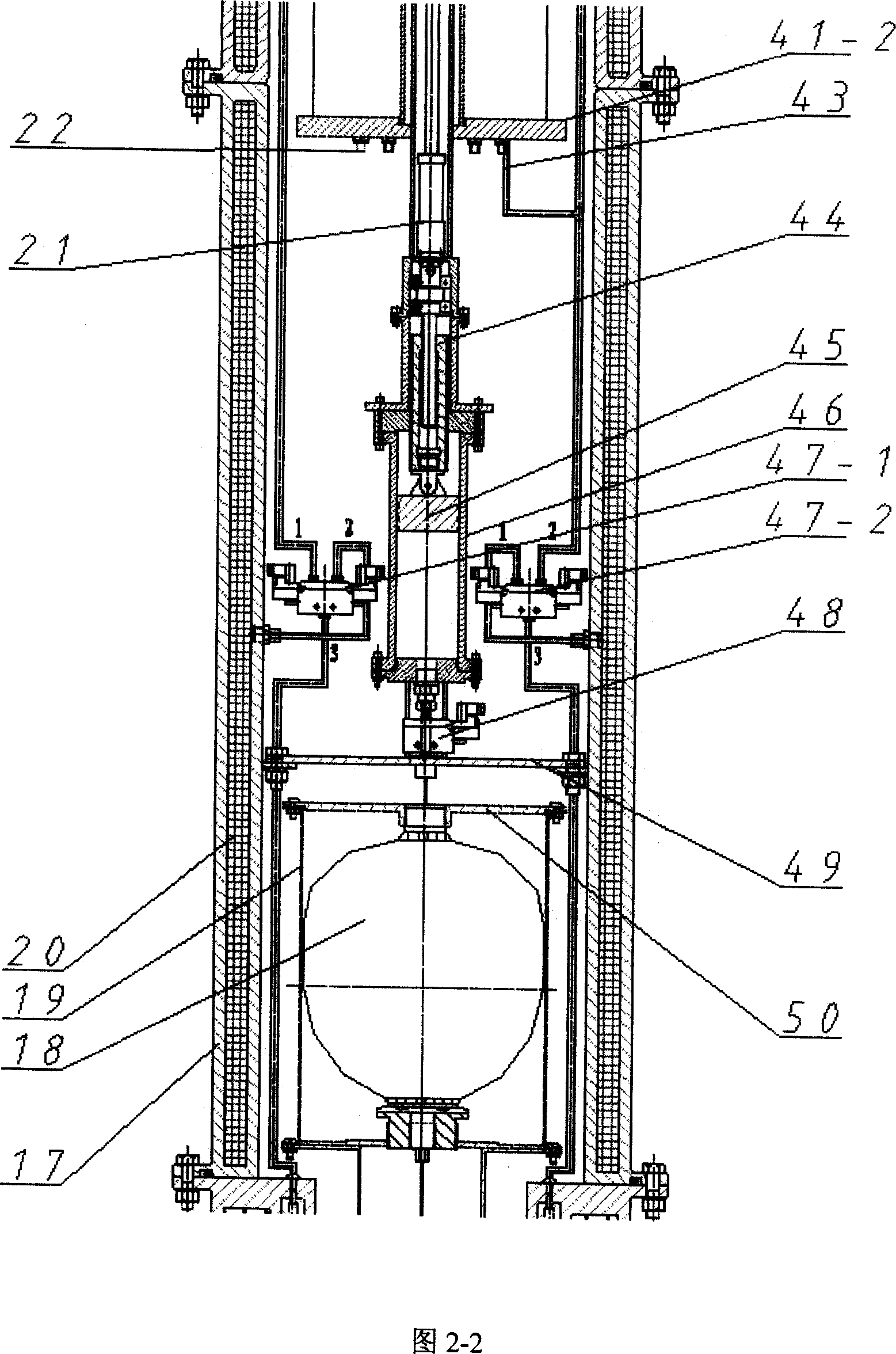

[0032] The structural principles of the present invention will be further described below through embodiments and with reference to the accompanying drawings. For this embodiment, the design parameters of the self-sustaining underwater profile buoy with composite energy are: the working depth is 1500M; the sealed chassis 4, the thermal engine working chamber 8, the thermal engine cooling chamber 17, the fuel cell cooling chamber 24 and the sealing head cover 31 Aluminum alloy materials are used to form the sealing cavity; the external dimensions are as follows: the total length of the sealing cavity is 2500mm, the diameter of the main shell is 250mm, and the wall thickness is 12mm. The outer skin bag 2 has a volume of 900 milliliters. The diameter of the sealing chamber of the hydraulic plunger pump is 90mm, and the piston stroke is 150mm. The hydraulic plunger pump casing 46, the piston 45, the nut screw pair 44, the plunger pump sealing cover and the support frame are all m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com