Reversible drive device with two single action cylinder implemented by closed abrasive

A single-acting cylinder and two-way driving technology, which is applied in the field of mechanical devices for grinding precision small holes and irregular holes, can solve the problems that the control loop cannot be synchronized, the synchronization is difficult to guarantee, and the structure is complicated, and the structure can be achieved. Simple, low manufacturing cost, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Introduce an embodiment of the present invention below:

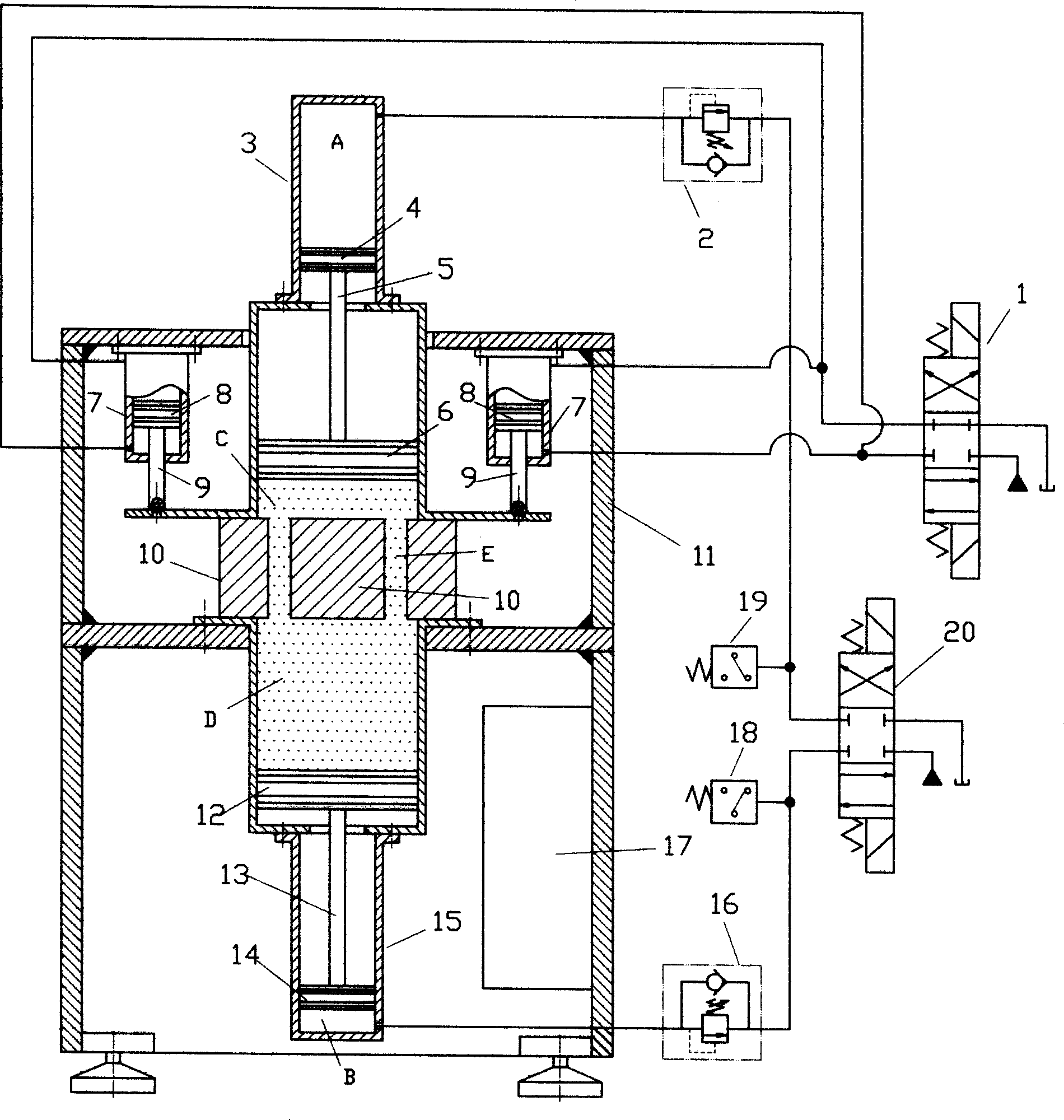

[0016] As shown in Figure 1, there are coaxial hydraulic cylinders on the frame 11, hydraulic locking devices on them, and hydraulic valves and electrical control devices that drive the hydraulic cylinders to work. The upper cylinder group 3 and the lower cylinder group 15 are a pair of two single-acting cylinders separately arranged. The tops of 7 are respectively fixed on the frame 11, and the lower cylinder group 15 is directly fixed on the frame 11.

[0017] The upper cylinder group 3 and the lower cylinder group are composed of two cylinders with different diameters, wherein the section with a small diameter is an oil cylinder, and the section with a large diameter is an abrasive cylinder. Pistons 4, 6, 14, 12 are respectively arranged in the cylinder, and two pistons 4, 6, 14, 12 with different diameters are respectively connected by piston rods 5, 13.

[0018] The chamber A of the upper cylinder group 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com