Preparation method of scutellaria root flavone general aglycone extract

A technology of baicalin flavonoids and total aglycones, which is applied in the field of extraction technology of baicalin flavones and total aglycones, can solve the problems of incomplete enzymatic hydrolysis reaction, high production cost, incomplete hydrolysis of baicalin, etc., and achieves simple and convenient steps and excellent production process Feasible and easy to extract and purify

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

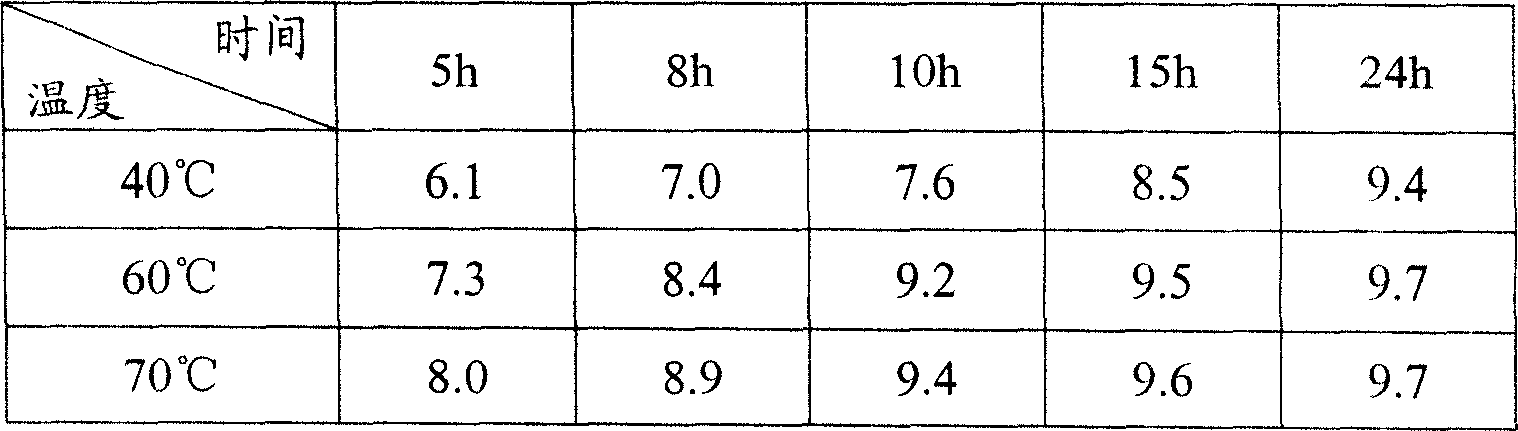

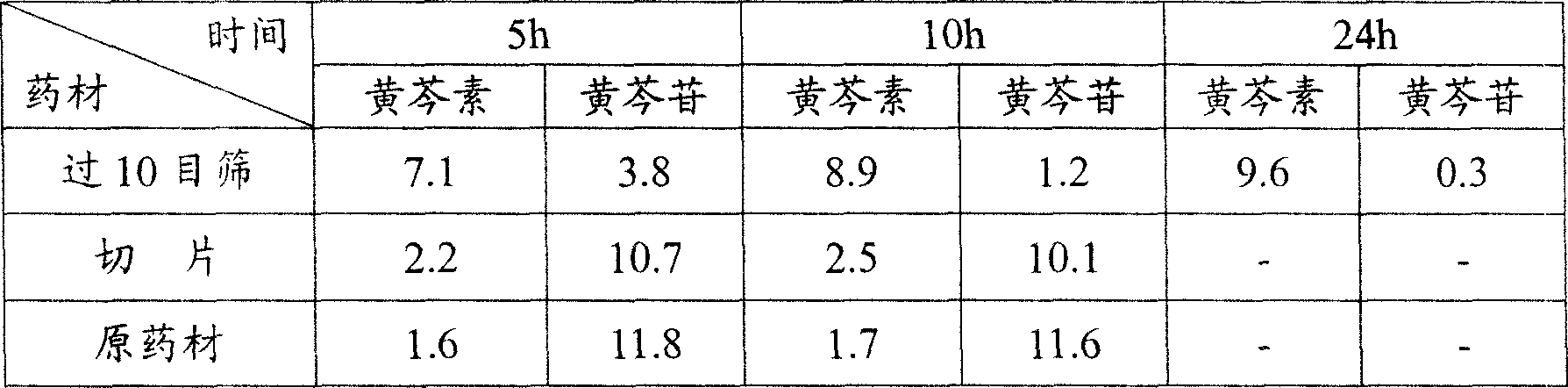

Embodiment 1

[0043] Take 10 kg of Scutellaria baicalensis and crush it through a 10-mesh sieve, add 60 liters of water, heat to 60°C and keep it warm for 10 hours; filter, discard the filtrate, extract the dregs after removing the filtrate with ethanol, and add 70% concentration of 80 liters of ethanol, reflux extraction twice, each time for 1 hour; filter, combine the ethanol extracts, recover the ethanol under reduced pressure until there is no alcohol smell, let it cool, and precipitate precipitates, filter the precipitates, and dry them to obtain the total aglycone extraction of Scutellaria baicalensis 1.7 kilograms of material, wherein baicalein content is 35.4%, and total flavonoid content is 75.1%.

Embodiment 2

[0045] Take 10 kg of Scutellaria baicalensis and crush it through a 15-mesh sieve, add 50 liters of water, heat to 65°C and keep it warm for 8 hours; filter, discard the filtrate, extract the dregs after removing the filtrate with ethanol, and add 85% concentration of 60 liters of ethanol, reflux extraction twice, each time 2.5 hours; filter, combine the ethanol extracts, recover the ethanol under reduced pressure until there is no alcohol smell, let it cool, and precipitate precipitates, filter the precipitates, dry, and obtain the total aglycone extraction of Scutellaria baicalensis 1.6 kg of material, wherein the baicalein content is 35.8%, and the total flavonoid content is 76.0%.

Embodiment 3

[0047] Take 10 kg of Scutellaria baicalensis and crush it through a 10-mesh sieve, add 80 liters of water, heat to 55°C and keep it warm for 15 hours; filter, discard the filtrate, extract the dregs after removing the filtrate with ethanol, and add 90% concentration of 50 liters of ethanol, reflux extraction 3 times, 0.5 hours each time; filter, combine ethanol extracts, recover ethanol under reduced pressure until there is no alcohol smell, let it cool, and precipitate precipitates, filter and dry the precipitates to obtain the total aglycone extraction of Scutellaria baicalensis 1.5 kilograms of material, wherein baicalein content is 36.5%, and total flavonoid content is 76.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com