Fault detection instrument of rotary equipment based on acoustic emission technique

An acoustic emission technology and rotating equipment technology, applied in the field of rotating equipment fault detectors, can solve problems such as simple functions, lack of real-time detection and analysis of collected signals, and difficulty in real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

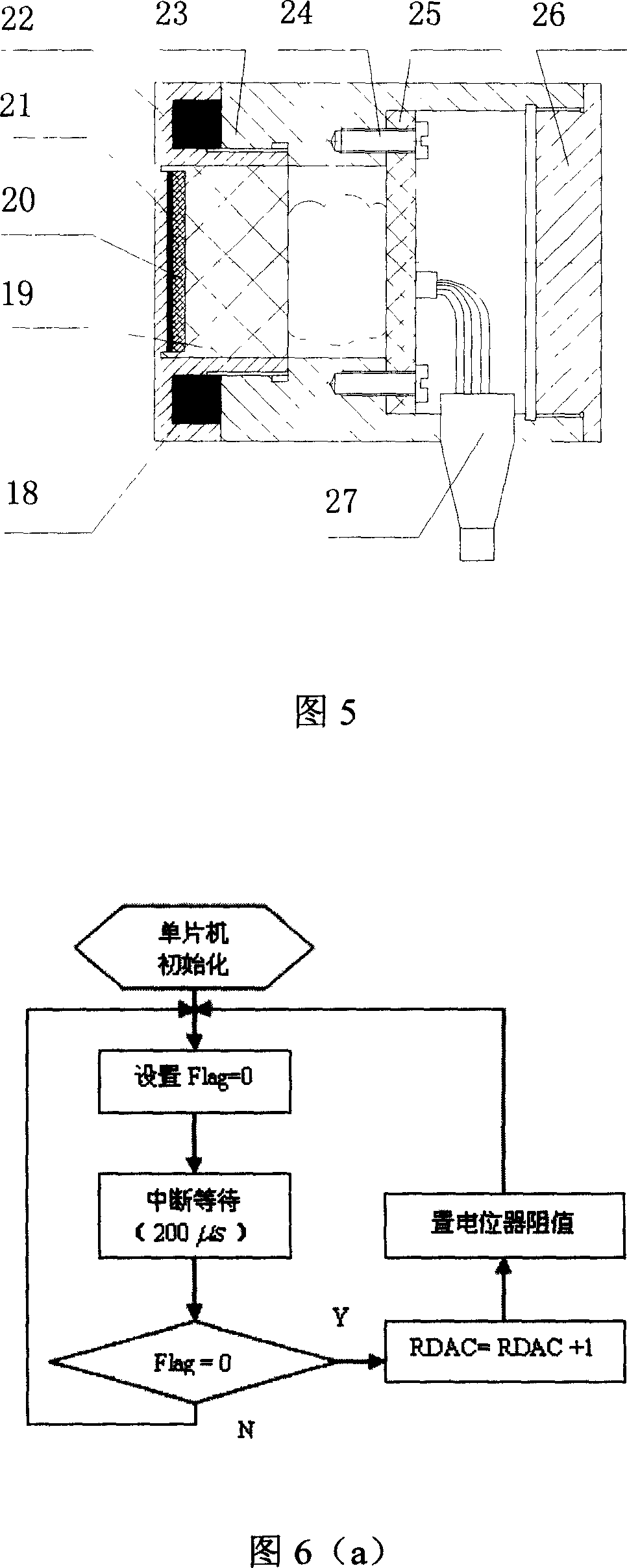

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

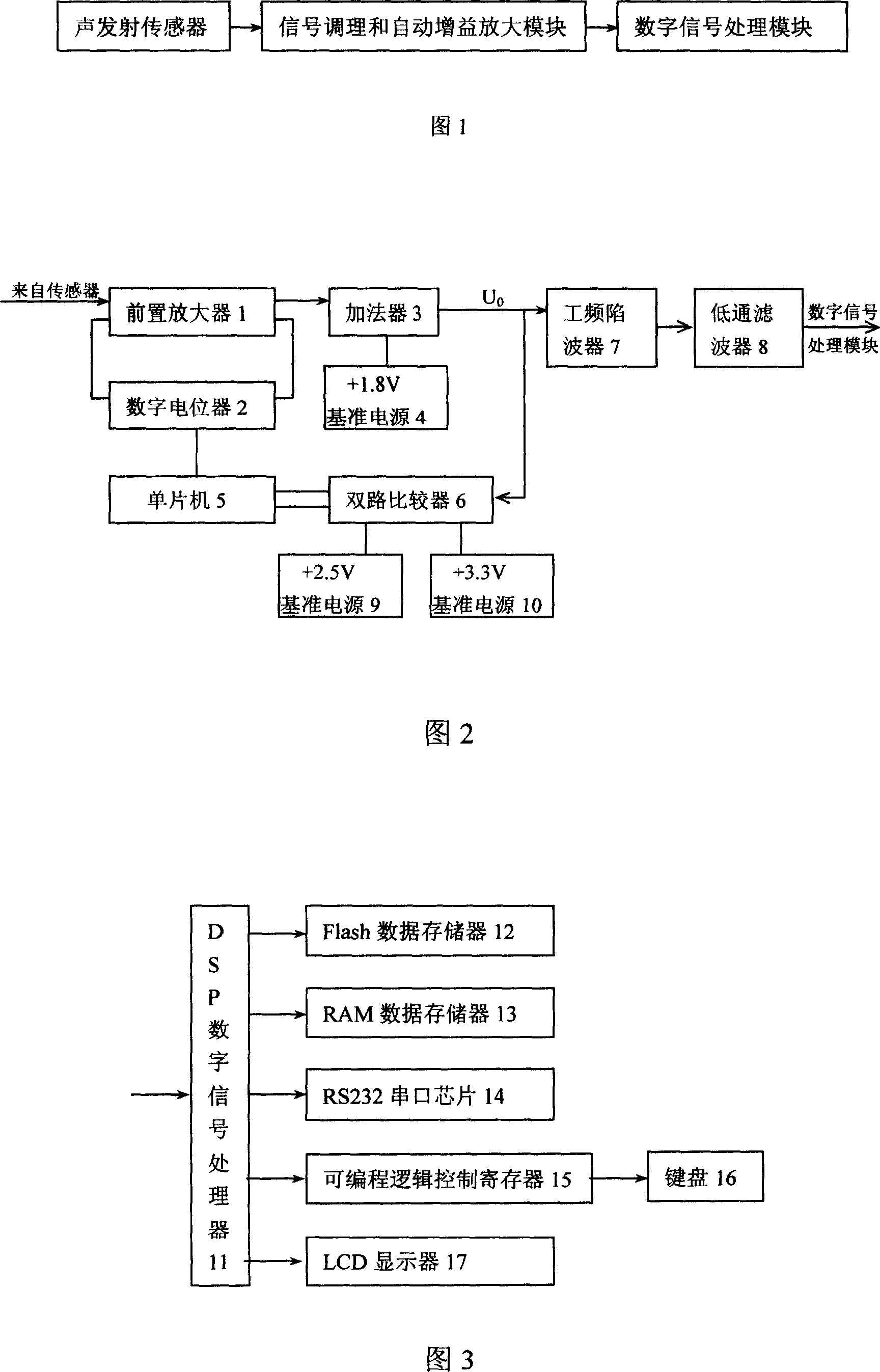

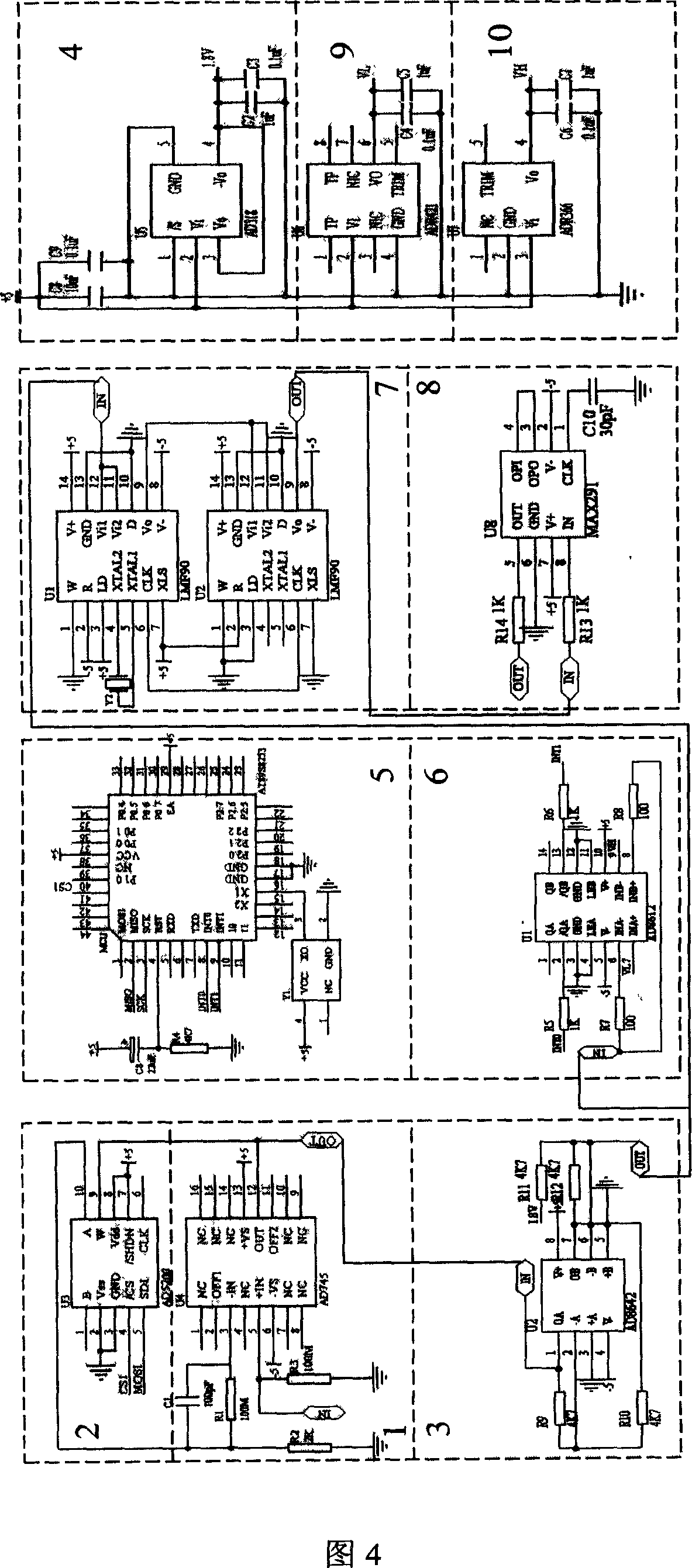

[0024] As shown in Figure 1, the rotating equipment fault detector consists of three parts: an acoustic emission sensor, a signal conditioning and automatic gain amplification module, and a digital signal processing module. The acoustic emission sensor detects the acoustic emission signal of the rotating equipment; the signal conditioning and automatic gain The amplification module realizes the pre-amplification, automatic gain control, power frequency notch, low-pass filtering and other functions of the output signal of the acoustic emission sensor, so that the high input impedance of the acoustic emission sensor becomes a low output impedance and amplifies the weak electrical signal, filters In addition to interference signals and useless signals, the voltage of the detection signal after signal conditioning and automatic gain amplification is controlled bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com