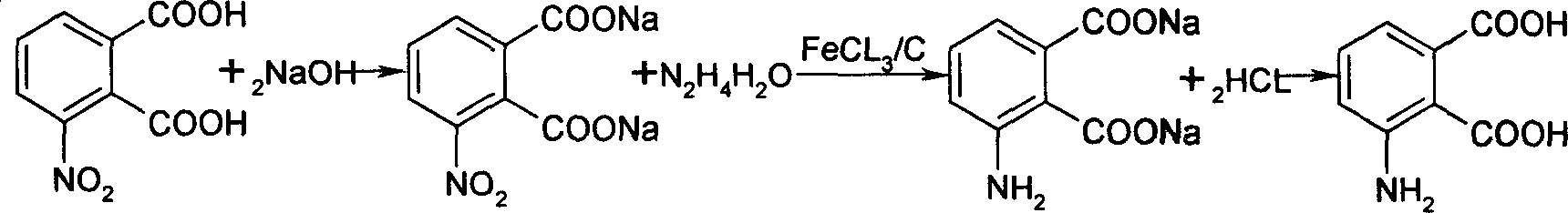

Method of preparing 3-aminophthalic acid from 3-nitrophthalic acid

A technology of nitrophthalic acid and aminophthalic acid, applied in chemical instruments and methods, cyanide reaction preparation, organic compound preparation, etc., can solve the problem that the product purity can only reach 90%, and the yield can only reach 90%. 50-60%, environmental pollution and other problems, to achieve the effect of low production cost, improve product purity and yield, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Add 260g of water to a 500ml three-neck flask, start stirring, then add 16g (96%) of sodium hydroxide, and then add 40g (0.19mol) of 3-nitrophthalic acid after dissolving, and stir to dissolve into a transparent solution ;

[0015] (2) Add catalyst (FeCl 3 / C): ferric chloride (FeCl 3 .6H 2 (2) 2.5g and activated carbon (for decolorization) 14g;

[0016] (3) Heat the catalyst-added solution to 95° C. (close to reflux), start to add 25 g of 80% hydrazine hydrate solution dropwise, continue heating to reflux reaction for 3.5 hours, after the reaction is completed, filter while it is hot, and collect the filtrate for later use;

[0017] (4) Add concentrated hydrochloric acid to the filtrate to acidify to PH3.5, cool and crystallize and filter, and dry at 80°C for 3 hours to obtain 31.9g of 3-aminophthalic acid finished product, the appearance is light yellow crystalline powder, purity: 96.42% (HPLC ), yield: 93%.

Embodiment 2

[0019] (1) Add 260g of water to a 500ml three-neck flask, start stirring, then add 18.5g (96%) of sodium hydroxide, and then add 40g (0.19mol) of 3-nitrophthalic acid after dissolving, stir and dissolve to become transparent solution;

[0020] (2) Add catalyst (FeCl 3 / C): ferric chloride (FeCl 3 .6H 2 (2) 3.5g and activated carbon (for decolorization) 16g;

[0021] (3) Heat the catalyst-added solution to 95° C. (close to reflux), start to add 29 g of 80% hydrazine hydrate solution dropwise, continue heating to reflux reaction for 4.5 hours, after the reaction is completed, filter while it is hot, and collect the filtrate for later use;

[0022] (4) Add concentrated hydrochloric acid to the filtrate to acidify to pH 3.5, cool and crystallize and filter, and dry at 80°C for 3 hours to obtain 32.8g of 3-aminophthalic acid finished product, which is light yellow crystalline powder with a purity of 96.5% ( HPLC), yield: 95%.

Embodiment 3

[0024] (1) Add 260g of water to a 500ml three-neck flask, start stirring, then add 22g (96%) of sodium hydroxide, and then add 40g (0.19mol) of 3-nitrophthalic acid after dissolving, and stir to dissolve into a transparent solution ;

[0025] (2) Add catalyst (FeCl 3 / C): ferric chloride (FeCl 3 .6H 2 (2) 4.2g and activated carbon (for decolorization) 19g;

[0026] (3) Heat the catalyst-added solution to 95° C. (close to reflux), start to drop 34 g of 80% hydrazine hydrate solution, continue heating to reflux reaction for 5 hours, after the reaction is completed, filter while it is hot, and collect the filtrate for later use;

[0027] (4) Add concentrated hydrochloric acid to the filtrate to acidify to PH3.5, cool and crystallize and filter, and dry at 80°C for 3 hours to obtain 33g of 3-aminophthalic acid finished product, which is light yellow crystalline powder in appearance, purity: 96.7% (HPLC ), yield: 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com