Energy-saving heat preservation thermally insulated wall and method of construction

A technology of thermal insulation and construction method, applied in the direction of wall, climate change adaptation, building components, etc., can solve the problems of complex structure, discount of material thermal insulation effect, increase construction cost, etc., to achieve simple pouring process, good thermal insulation effect, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

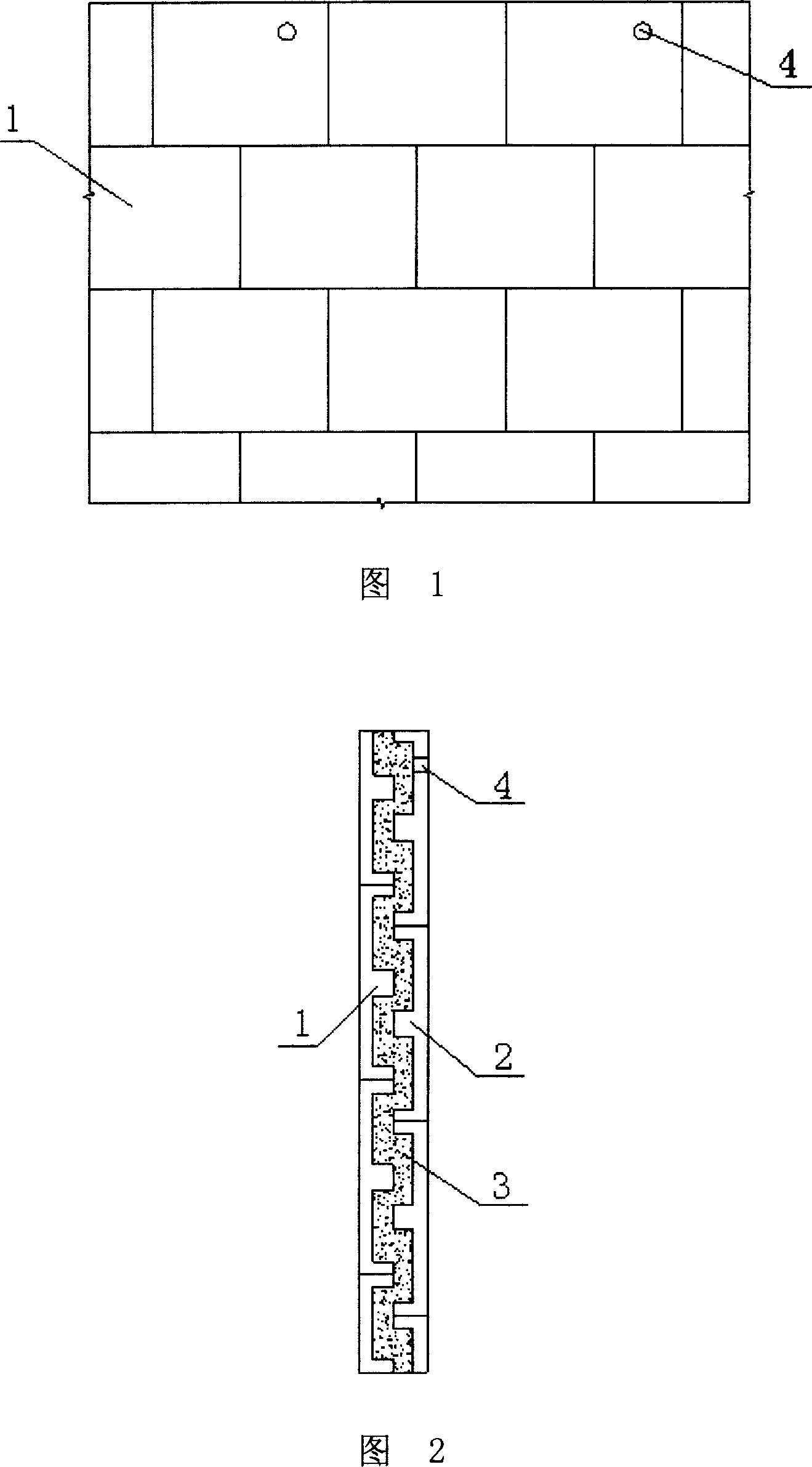

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] Referring to the accompanying drawings, this embodiment consists of three parts: an inner wall 1, a middle wall 3, and an outer wall 2. The inner wall 1 and the outer wall 2 are prefabricated by foamed concrete with an "E"-shaped cross section and high strength. It is made of blocks, and the middle wall 3 is a foam concrete insulation layer with good thermal insulation performance which is integrally poured on site. The foam concrete prefabricated block is provided with a foam concrete injection port 4 .

[0015] Masonry method: (1) Use foam concrete prefabricated blocks with "E" shaped cross-section and foam concrete injection port 4 to build the inner wall 1 and outer wall 2; (2) use foam concrete as thermal insulation material The injection process is injected between the inner wall body 1 and the outer wall body 2 through the injection port 4 of the prefabricate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com