Pulsating heat pipe heating panel using microcapsule phase-change thermal storage fluid as operating means

A phase change heat storage, microcapsule technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc., can solve the problem of large contact thermal resistance, affecting heat dissipation capacity, and unreliable operation of flow direction control valves and other problems, to achieve the effect of easy horizontal installation and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below with reference to the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto.

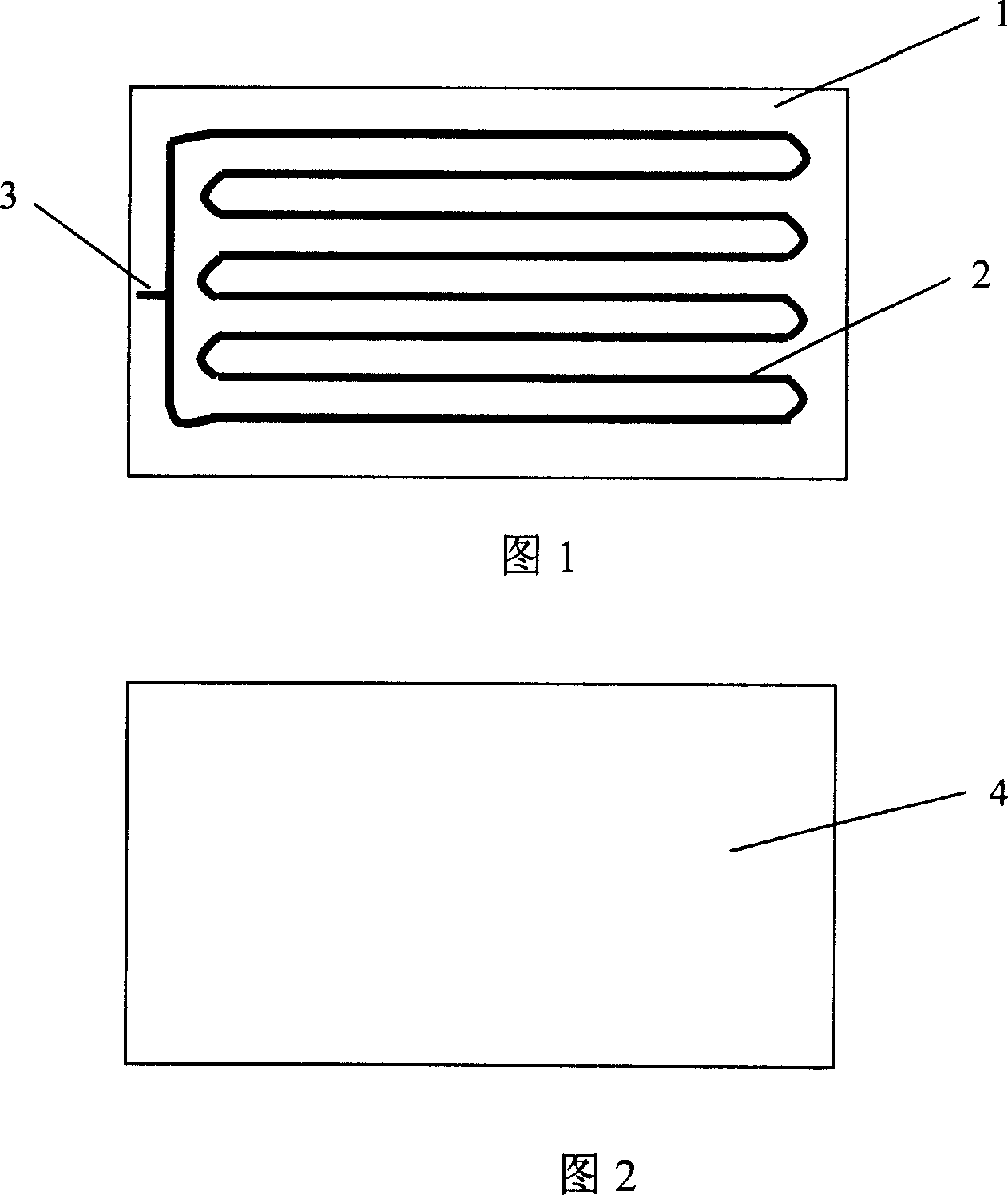

[0019] As shown in Figures 1 and 2, the pulsating heat pipe heat sink with microcapsule phase change thermal storage fluid as the working medium includes a base plate 1 and a cover plate 4, and the base plate 1 and cover plate 4 together form a completely closed cavity; the base plate 1 has a serpentine groove 2, the number of bends in the serpentine groove 2 is 8, and the cross section is a rectangle of 0.5mm×0.5mm; the serpentine groove 2 is equipped with microcapsule phase change heat storage fluid FS-39E fluid The serpentine groove 2 of the working medium communicates with the inlet 3 on the substrate 1 . Microcapsule phase change heat storage fluid FS-39E is one of the series of heat storage materials produced by Mitsubishi Paper Co., Ltd., with a phase change temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com