Steel sheet for extreme thin container and method for manufacturing the same

A manufacturing method, steel plate technology, applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve problems such as deformation, and achieve the effect of improving deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

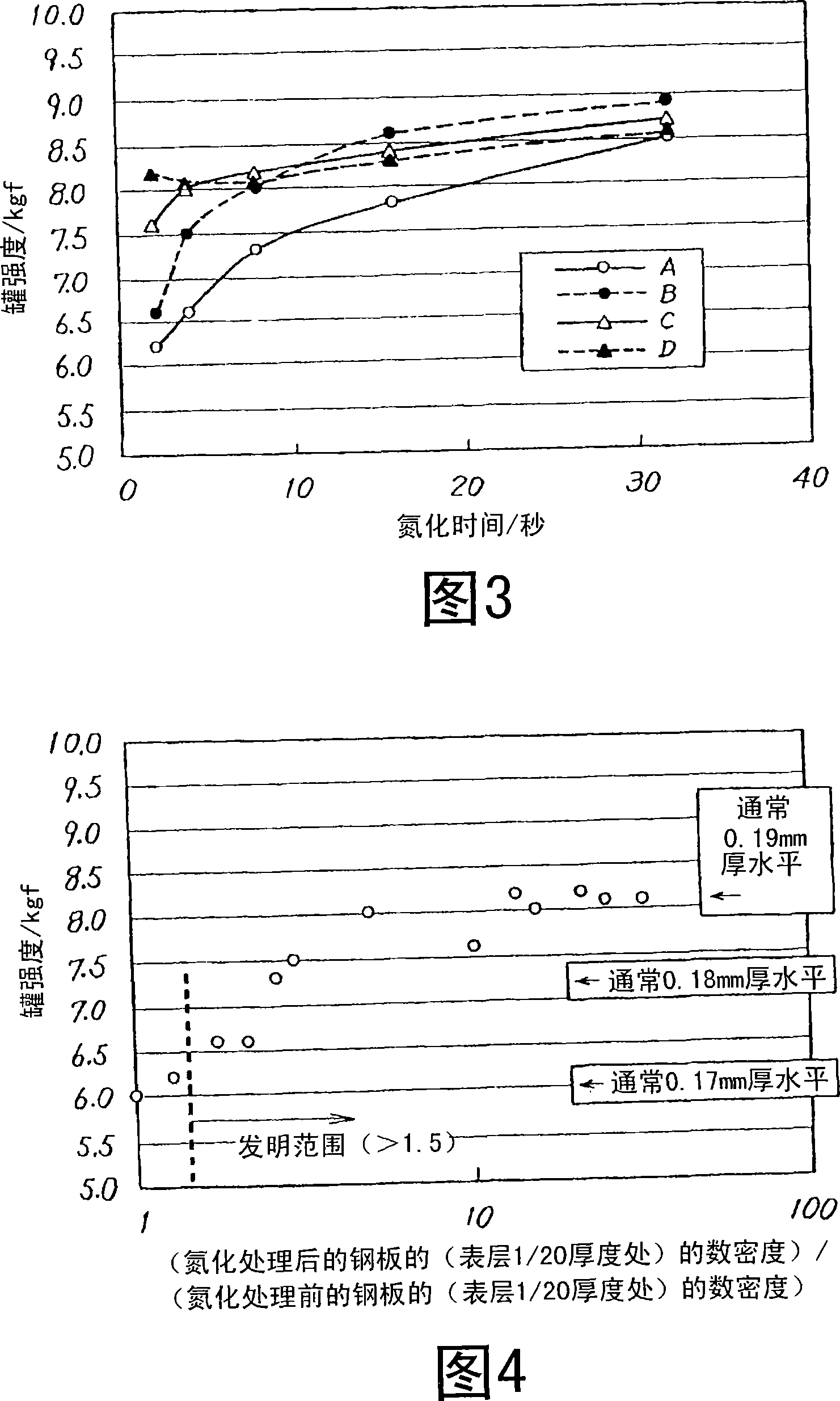

[0104] For a three-piece can whose barrel portion is formed by welding, a three-piece can barrel is manufactured using a steel plate whose nitrides are controlled by changing the nitriding conditions. Deformation resistance was measured when a cylindrical die with a diameter of 10 mm and a length of 40 mm was squeezed into the barrel of a can, and the end of the cap was flanged as in the usual cap crimping.

[0105] For the deformation test, the relationship between the extrusion amount of the mold and the extrusion load is shown in Figure 2, and an inflection point appears at a certain load. The load at which this inflection point appeared was used as an index of deformation resistance. The higher the value, the smaller the deformation caused by external force and the better the deformation resistance.

[0106] Furthermore, for flange forming, the length of the flange until a crack appeared in the flange portion was measured. The longer this length is, the better the flange...

Embodiment 2

[0112] Continuous casting is used to manufacture a 250mm thick billet containing C: 0.02%, Si: 0.02%, Mn: 0.2%, P: 0.01%, S: 0.01%, Al: 0.04%, and N: 0.002% in mass %. Slab heating temperature: 1100°C, finish rolling temperature: 880°C, and coiling temperature: 600°C were used to manufacture a 2.0 mm thick hot-rolled sheet. Pickling and cold rolling to 0.17mm, and recrystallization annealing at 650°C for 30 seconds in a continuous annealing unit.

[0113] A part of the material passes through a nitriding treatment furnace connected to the annealing furnace of the continuous annealing unit and filled with an atmosphere containing ammonia for nitriding treatment. In the nitriding treatment furnace, no heating equipment was installed, and the plate material in the state heated in the recrystallization annealing furnace was entered into the nitriding treatment furnace at 650° C. to perform nitriding. The atmosphere in the nitriding furnace is heated by the heat brought in by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com