Supersonic foreign fiber sorting and clearing machine

An ultrasonic and sorting machine technology, which is applied in the direction of sorting and analyzing solids using sound waves/ultrasonic waves/infrasonic waves, etc., can solve the problems of high price, high manufacturing cost, cotton fiber damage, etc., and achieve high removal efficiency, simple structure, Versatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

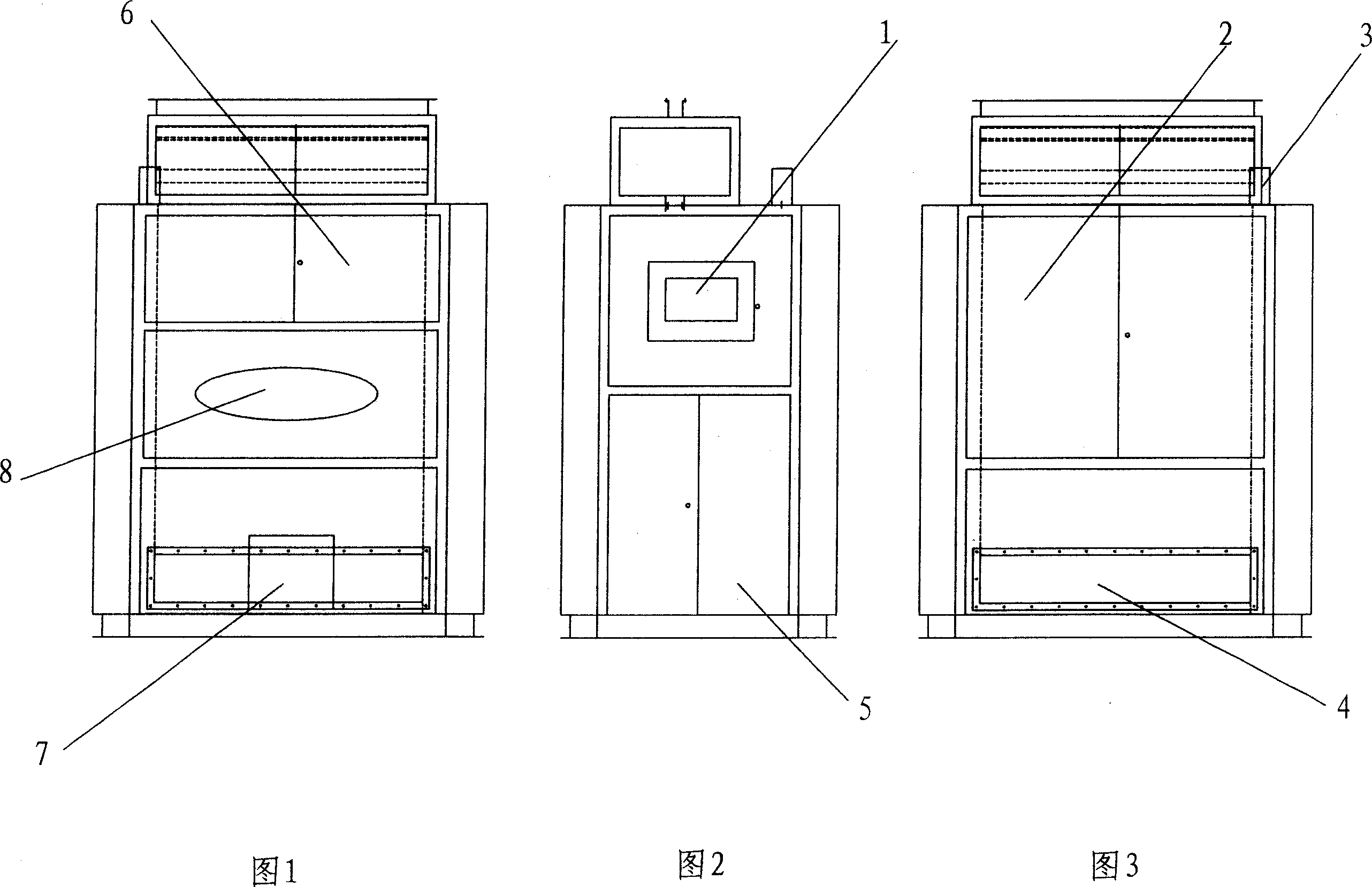

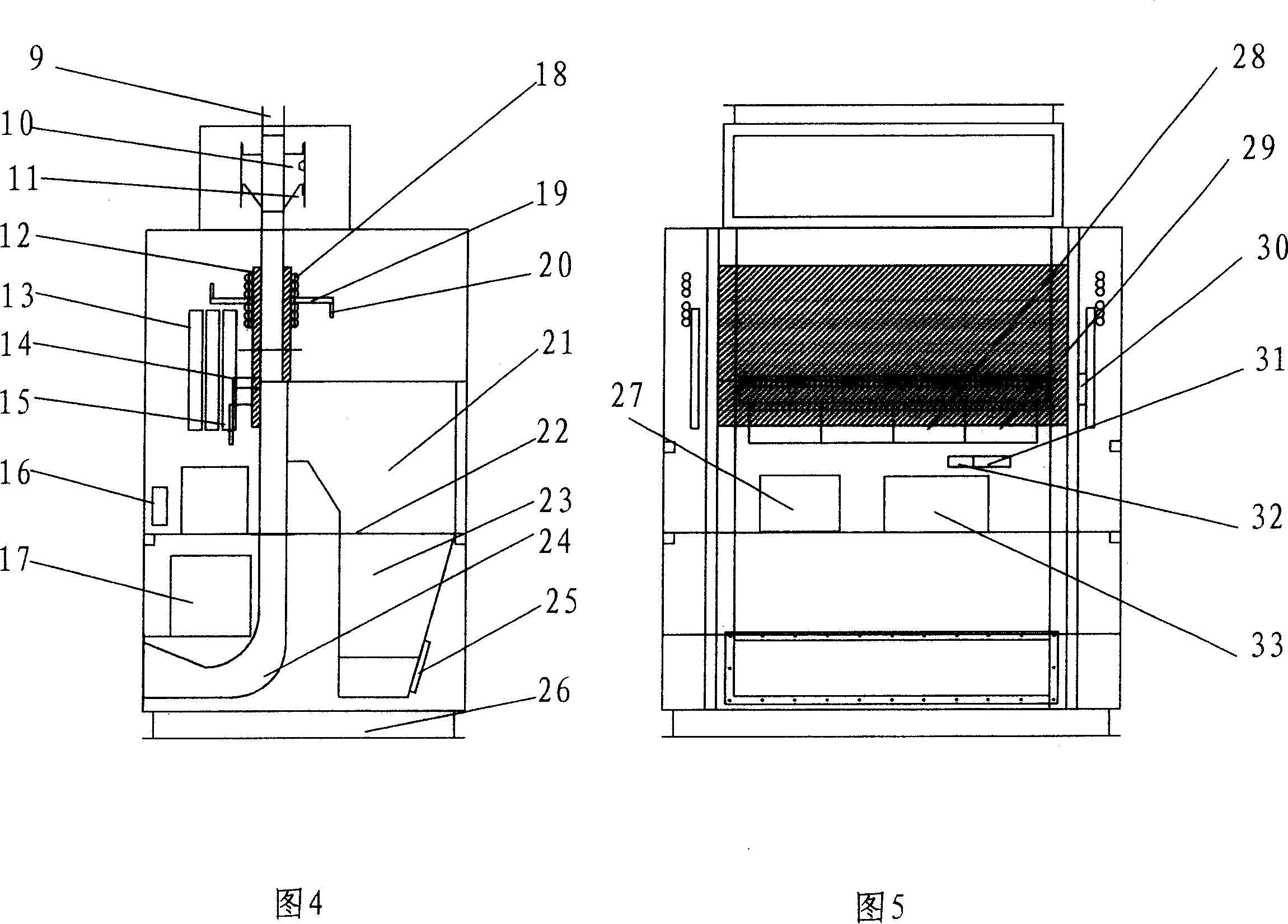

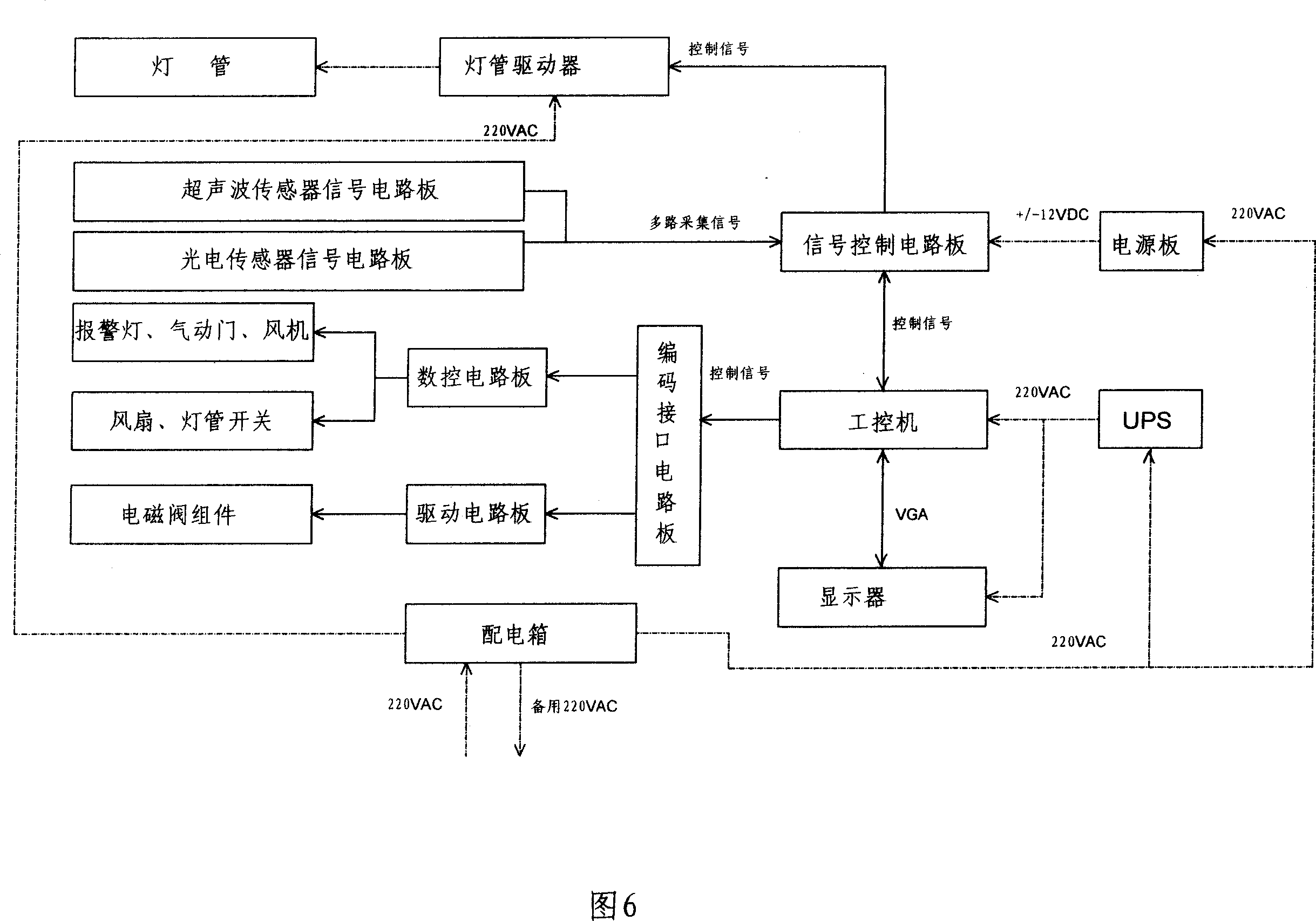

[0019] The present invention mainly consists of a display 1, a front door 2, an alarm light 3, a cotton outlet 4, a power distribution box 5, a rear upper side door 6, a waste cotton removal port 7, an observation window 8, a top cotton inlet duct 9, an ultrasonic sensor 10, Ultrasonic signal circuit board 11, plexiglass 12, lamp driver 13, high-speed drive solenoid valve 14, drive circuit board 15, lamp switch 16, gas storage tank 17, lamp 18, photoelectric sensor and bracket 19, photoelectric sensor signal circuit Board 20, middle air duct 21, middle partition 22, waste cotton box 23, bottom air duct 24, pneumatic door 25, base 26, uninterruptible power supply 27, numerical control circuit board 28, coding interface circuit board 29, fan 30, signal Control circuit 31, power board 32, industrial computer 33, housing 34 and other components.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com