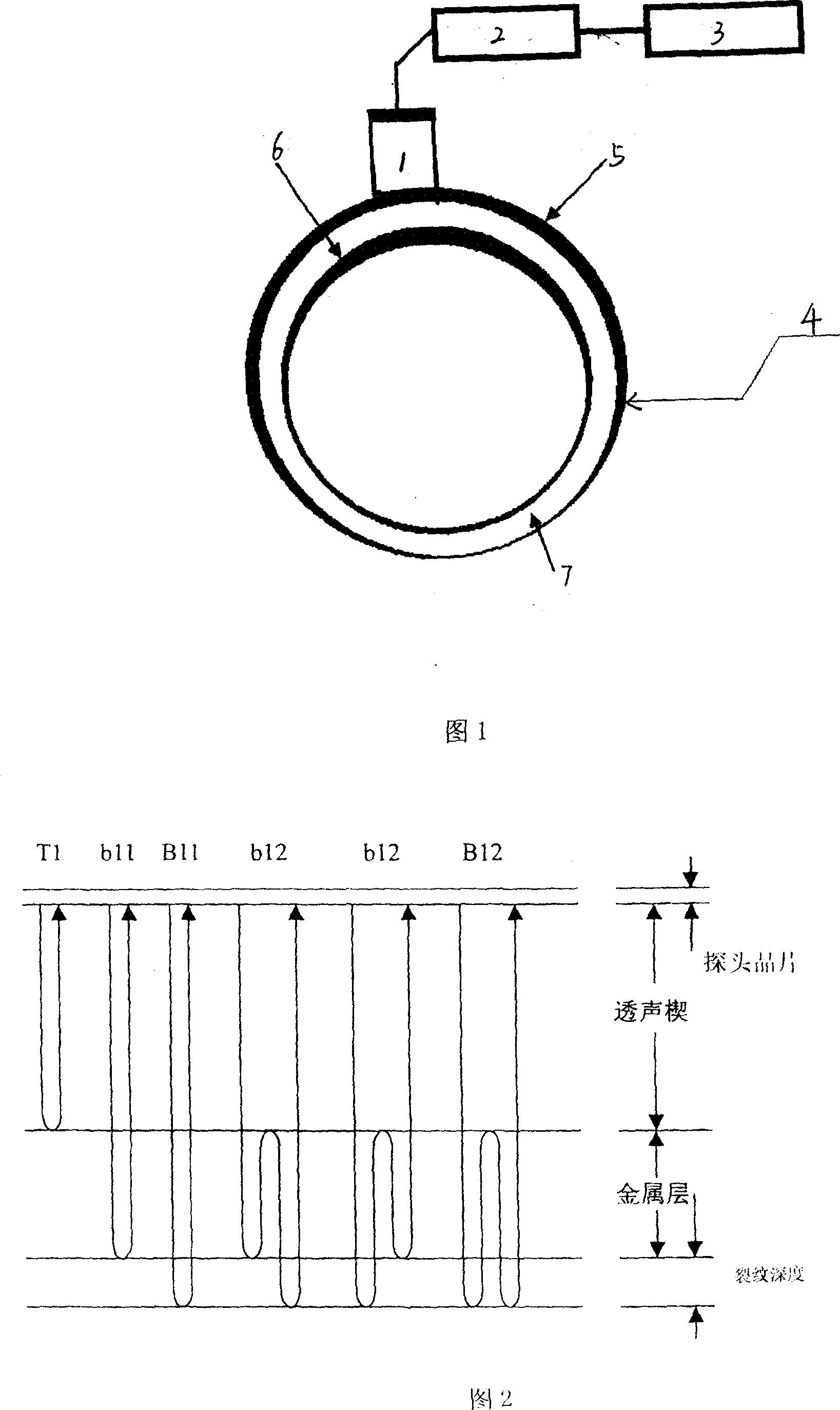

Method for detecting microcrack of high temperature furnace inner wall of furnace and device therefor

A micro-crack, high-temperature furnace technology, applied in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc., can solve the problem of inability to effectively detect micro-cracks on the inner wall of high-temperature furnace tubes, and achieve convenient measurement, accurate measurement results, The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

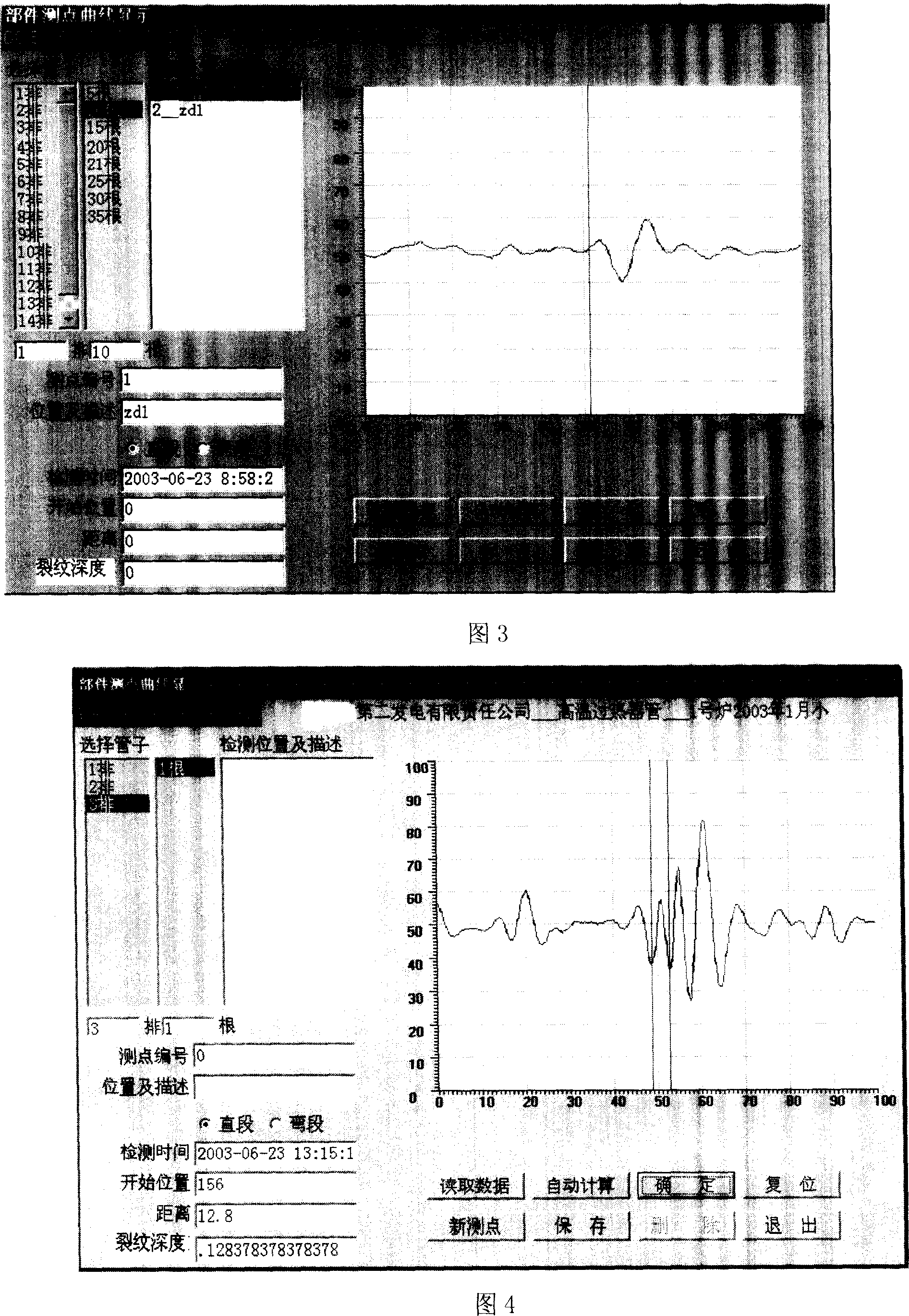

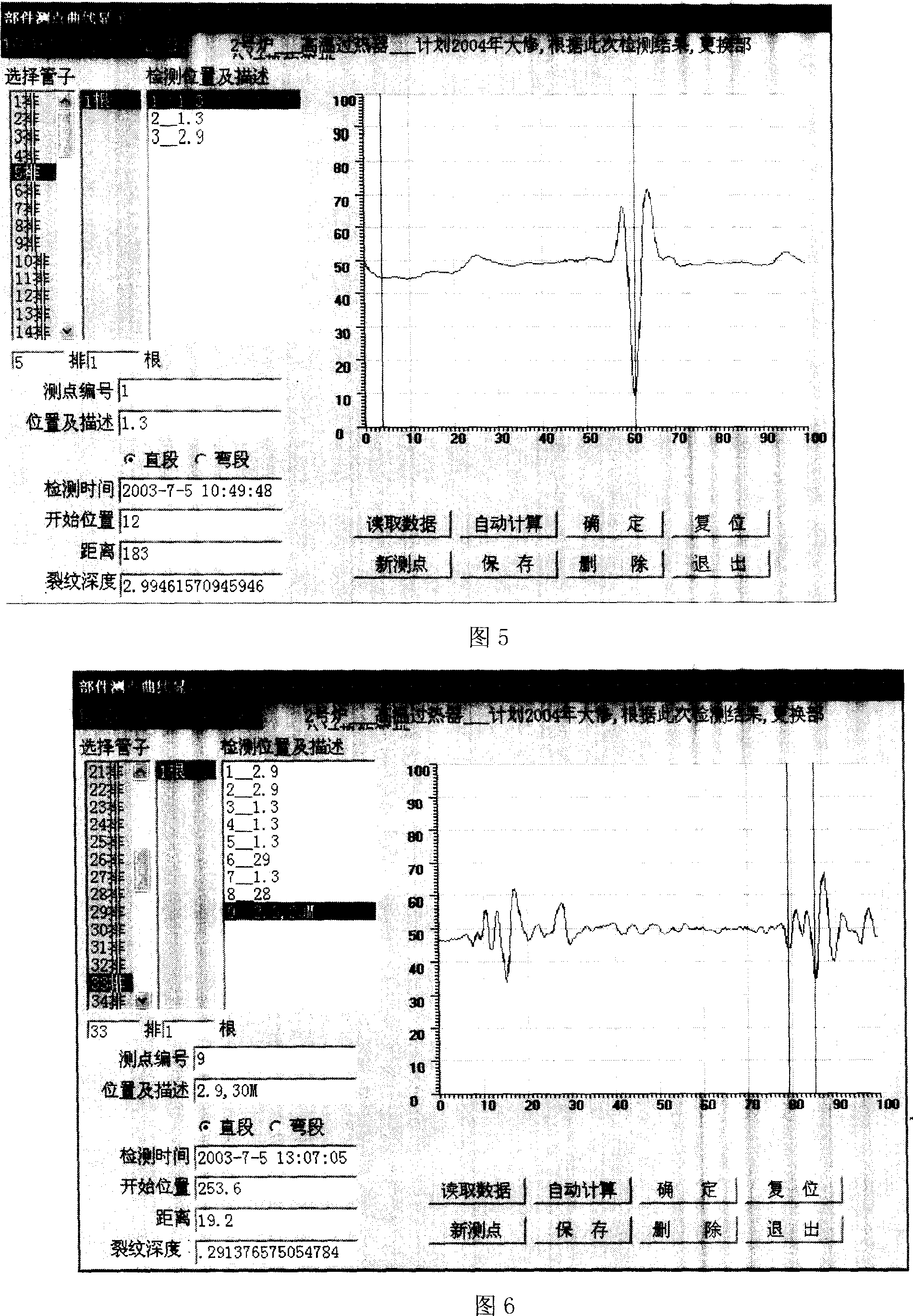

Embodiment example 1

[0040] A power plant has a 130t / h boiler. During the four years of operation, the high-temperature superheater tube is 12CrlMoV, with a specification of φ42×3.5. The tube burst occurred four times. In order to analyze the cause of the tube burst, the device of the present invention was used to measure its Oxidation corrosion and cracks on the inner wall of the high temperature superheater tube. There are 60 rows of this superheater, and a total of 200 points were detected. Two suspicious waveforms were detected in the area where the tube burst in the past, while the waveforms of other tubes were basically the same. The waveforms are exemplified below. Figure 5 is the waveform without oxidation cracks, and Figure 6 is the waveform with oxidation microcracks.

[0041] Through this inspection, two pieces of foreign matter were found in the header box higher than the entrance with the OLYMPUS video endoscope (the size of the foreign matter is 40mm×60mm, while the height of the tub...

Embodiment example 2

[0043] The material of the water wall of a thermal power plant is 20g steel, the specification is φ65×5. Leakage occurs during operation for 80,000 hours. The explosion is located in the water wall tube facing the fire surface in the form of a window and cracks longitudinally along the tube with a maximum longitudinal opening of 52.36 as shown in the figure below. mm, the maximum lateral opening is 45.52mm. There is no obvious plastic deformation in the pipe section near the burst, and the edge of the burst is rough, showing a brittle fracture morphology. Through metallographic analysis and macroscopic analysis, it was confirmed that the tube explosion was caused by hydrogen embrittlement. Because the occurrence of hydrogen embrittlement has the characteristics of large area and abruptness, conventional inspection is relatively difficult, but the invention can quickly inspect the conditions of other pipes.

[0044]In order to check the conditions of other pipes, a large-scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com