Production process of eliminating simple substance sulphur from SO2 gas

A production process, a technology for elemental sulfur, applied in the fields of sulfur compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of complex purity process, high technical difficulty and high production cost, and achieve simple process, advanced technology and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

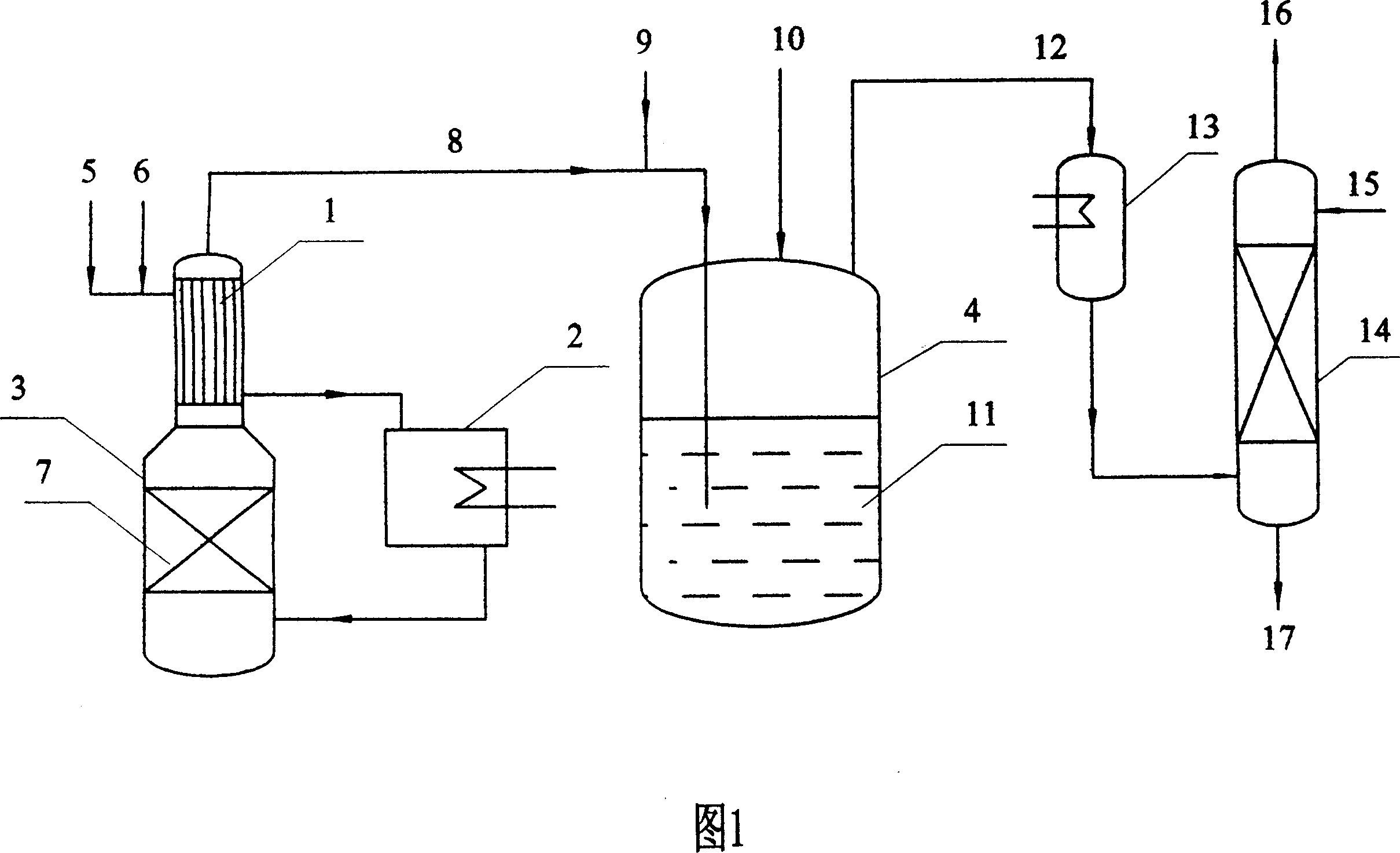

[0007] Referring to Figure 1, the unpurified sulfur dioxide gas 6 is mixed with air or oxygen 5 and then enters the heat exchanger 1 for preheating, and then the mixed gas is heated to 300-700°C by the gas heater 2, and then enters the Sulfur trioxide generator 3 of divanadium catalyst, sulfur dioxide and oxygen react here to generate sulfur trioxide, and after heat exchange through heat exchanger 1, it is mixed with sulfur dioxide gas 9 containing sublimated sulfur, and enters the 20- In the desulfurization reactor 4 of 30% oleum, the sulfur trioxide in the oleum reacts with the sublimated sulfur at 100-140°C to convert the sublimated sulfur into sulfur dioxide, and the gas 12 from the desulfurization reactor contains a small amount Sulfur trioxide gas, after passing through the cooler 13, enters the concentrated sulfuric acid washing tower 14, and is washed with the concentrated sulfuric acid 15 of 90-98.5% with a concentration, and sulfur trioxide is absorbed by the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com