Light emitted semiconductor assembly package structure and producing method thereof

A technology of light-emitting semiconductors and packaging structures, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc. It can solve problems such as uneven color temperature and precipitation, achieve uniform color temperature, avoid gaps, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

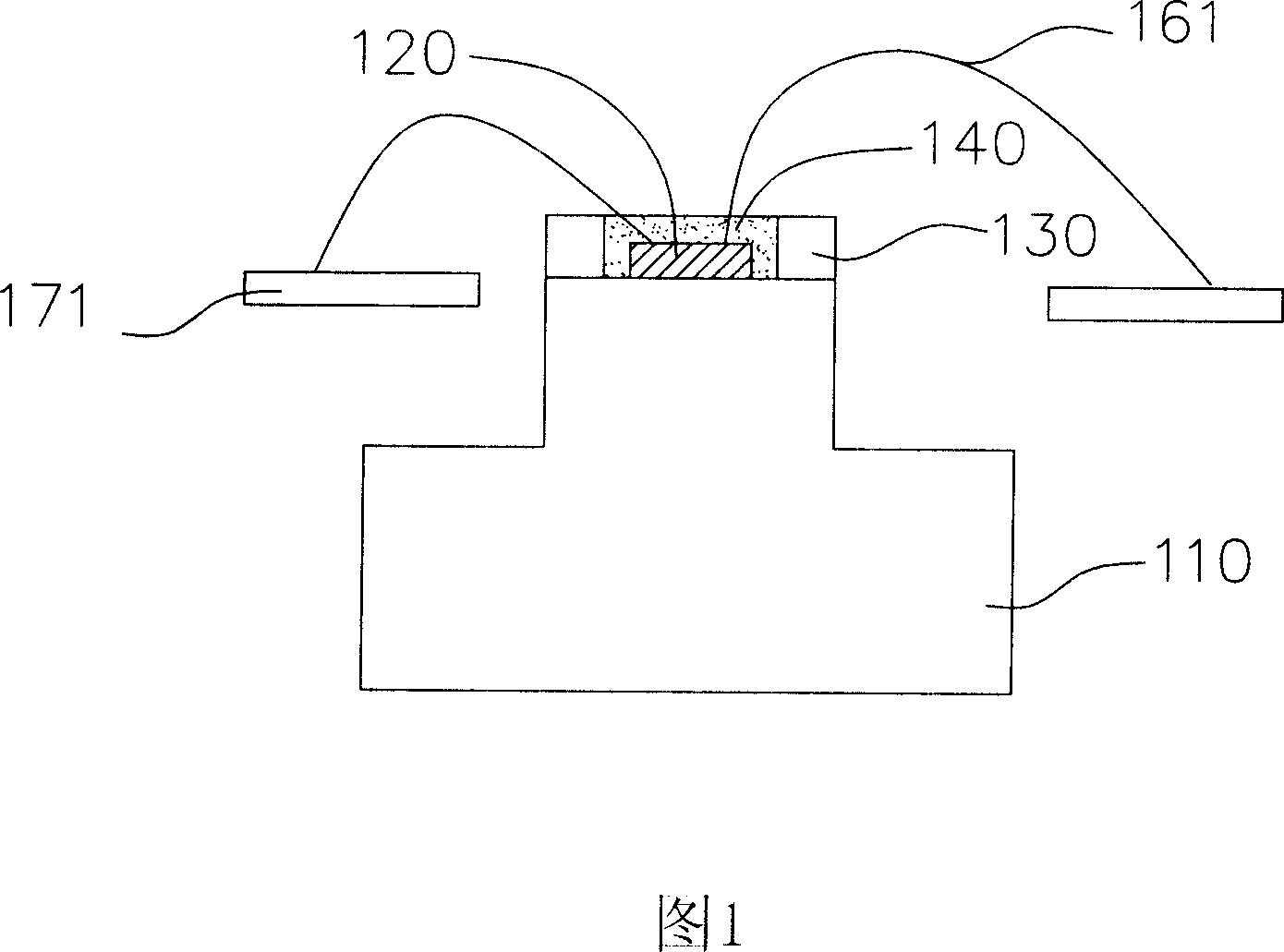

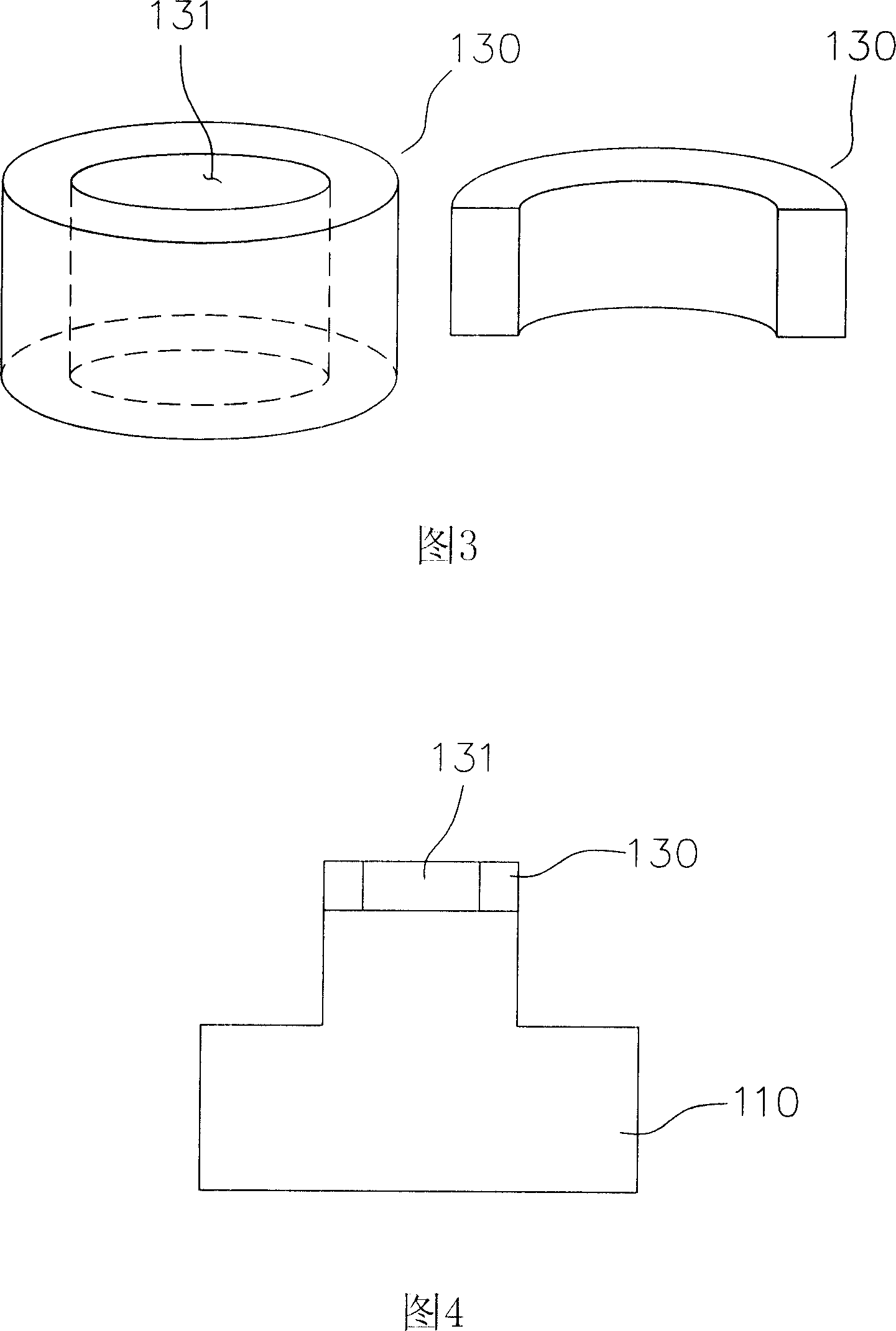

[0028] Please refer to FIG. 1 , which shows a cross-sectional view of a packaging structure of a light-emitting semiconductor device of the present invention. The packaging structure 100 of light-emitting semiconductor components includes a substrate 110 , a light-emitting semiconductor component 120 , a phosphor colloid fixing structure 130 and a phosphor colloid coating layer 140 .

[0029] The light-emitting semiconductor component 120 and the phosphor colloid fixing structure 130 are disposed on the base 110; wherein, the phosphor colloid fixing structure 130 has an opening and surrounds the light-emitting semiconductor component 120, and the metal wire 161 is electrically connected to the light-emitting semiconductor component 120 between the positive and negative electrodes and the electric energy input electrode 171. The phosphor colloid coating layer 140 is filled in the phosphor colloid fixing structure 130 through the opening of the phosphor colloid fixing structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com