Cylindrical alkaline battery

An alkaline battery, cylindrical technology, used in dry batteries, battery electrodes, active material electrodes, etc., can solve the problems of promoting zinc corrosion, reducing the quality of liquid leakage, and increasing the production of hydrogen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

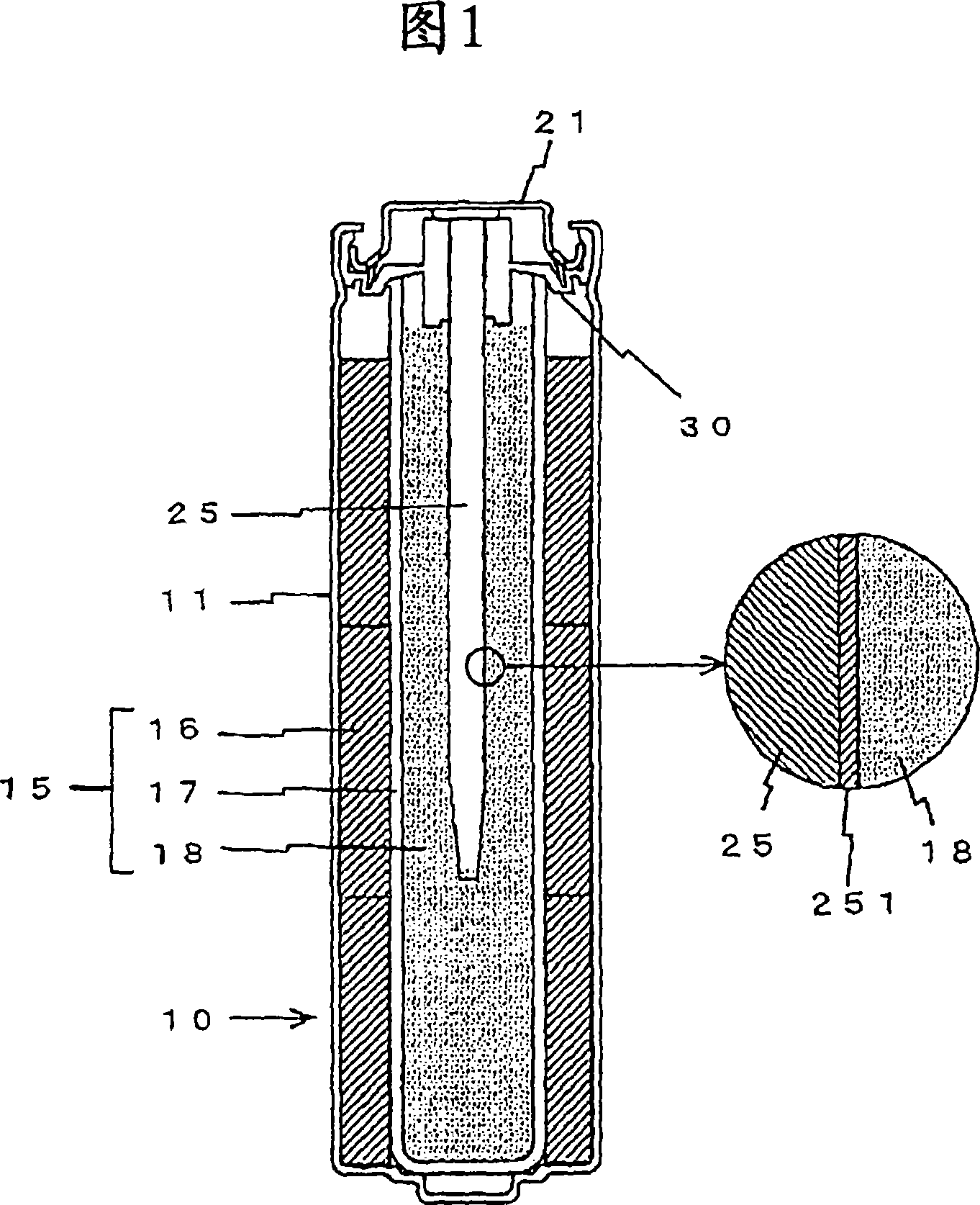

[0039] As Example 1, a cylindrical alkaline battery (LR03) having the structure shown in FIG. 1 was prepared according to Specification 1.

[0040] == Specification 1 ==

[0041] (1) Cathode mixture: prepared from electrolytic manganese dioxide, graphite as a conductive material, binder and 40% KOH aqueous solution.

[0042] (2) Anode gel: prepared from zinc alloy with a particle size in the range of 50-250 mesh, 40% KOH aqueous solution and polyacrylic acid as a thickening material.

[0043] (3) Anode gel additive: no

[0044] (4) Anode electron collector: a brass plate is used as a substrate, and its surface is electrolessly plated with Sn.

[0045] (5) The thickness of the electroless coating on the surface of the anode electron collector: 0.07-0.095 microns

Embodiment 2

[0047] As Example 2, a cylindrical alkaline battery (LR03) having the structure shown in FIG. 1 was prepared according to Specification 2.

[0048] == Specification 2 ==

[0049] (1) Cathode mixture: same as in specification 1.

[0050] (2) Anode gel: Same as in specification 1.

[0051] (3) Anode gel additive: add indium oxide at a concentration of 100 ppm to the anode gel.

[0052] (4) Anode electron collector: Same as in specification 1.

[0053] (5) Thickness of the electroless plating layer on the surface of the anode electron collector: the same as in specification 1 (0.07-0.095 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com