Dielectric ceramic, process for producing the same, and laminated ceramic capacitor

A technology of ceramic capacitors and dielectrics, which is applied in the field of laminated ceramic capacitors, can solve the problems of poor durability under high temperature load, lower dielectric constant, lower reliability, etc., and achieve improved sinterability, improved reduction resistance, and improved reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

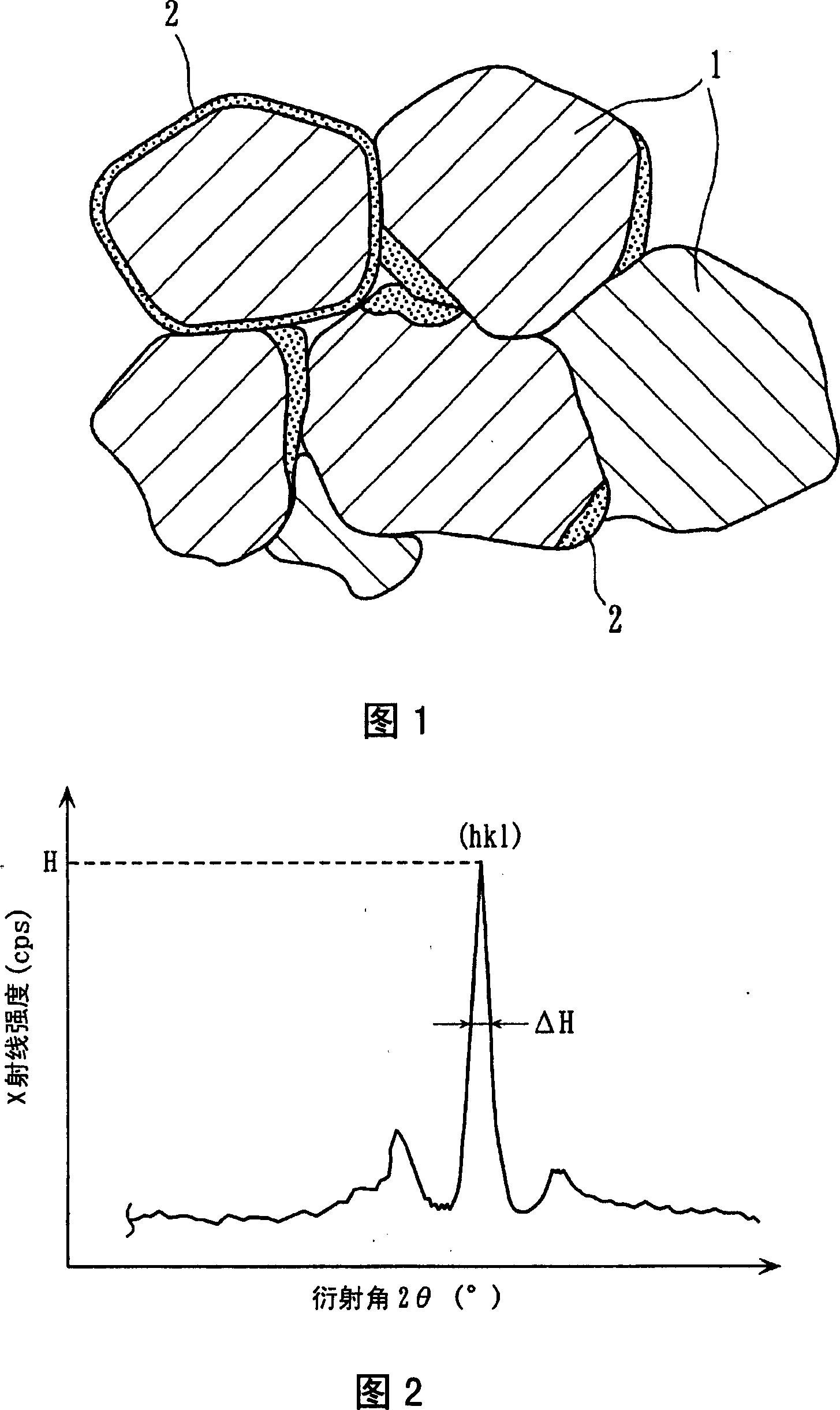

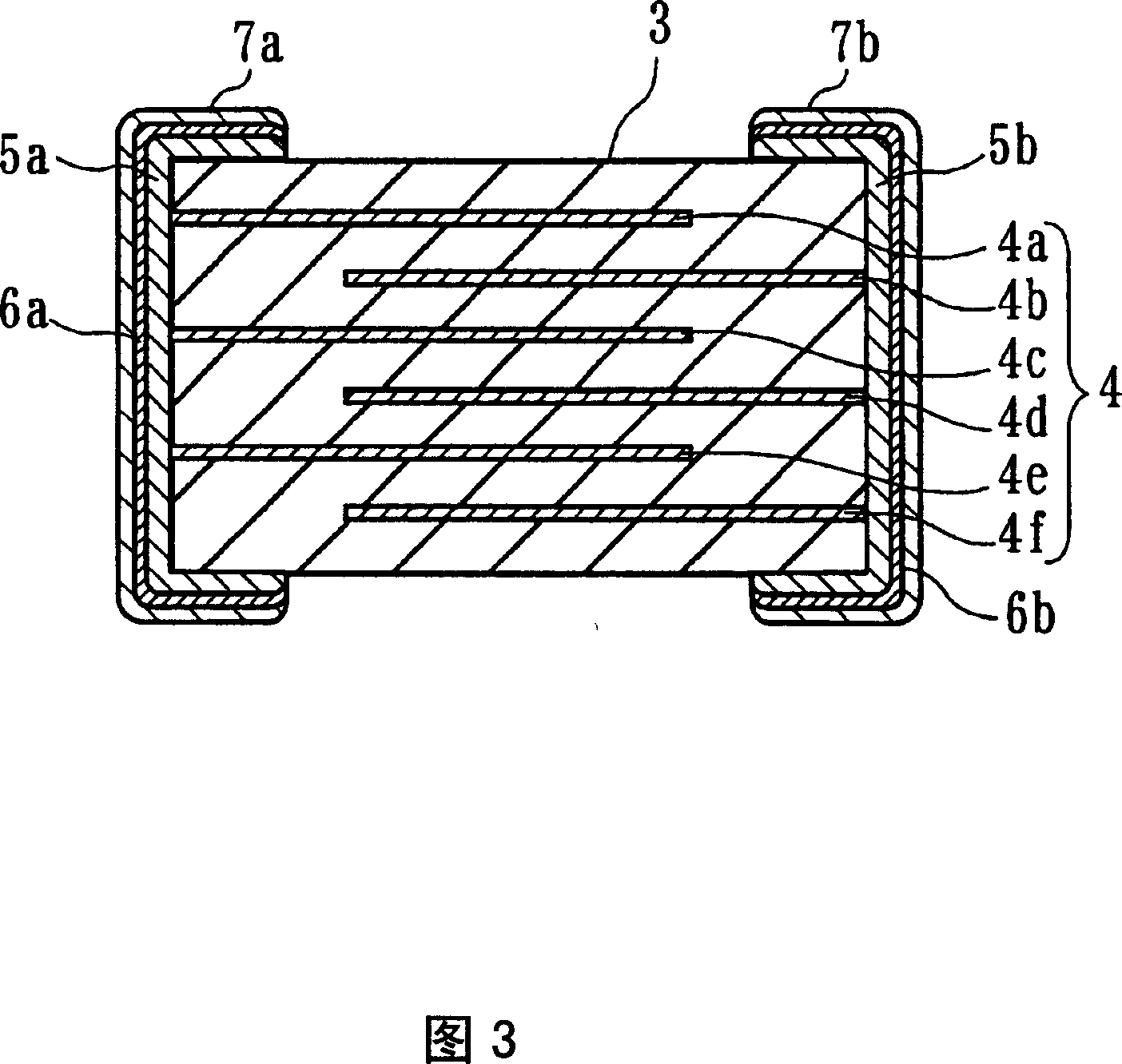

[0094] First, prepare BaCO with an average particle size of 50 nm as a ceramic raw material 3 , CaCO 3 、TiO 2 and V 2 o 5 , These ceramic raw materials were weighed according to a prescribed amount, and after putting the weighed objects into a ball mill, they were kneaded and pulverized by a wet method for 24 hours. Next, heat treatment is carried out at a temperature of 1000-1150°C, and the chemical composition formula (Ba 0.90 Ca 0.10 )(Ti 0.999 V 0.001 )O 3 Main components of Examples 1-3 and Comparative Examples 1-3 shown.

[0095] Then, the X-ray spectrum of each of these main components was measured by XRD (X-Ray Diffraction: X-ray diffraction device), and the half width ΔH (°) was measured.

[0096] Then, prepare Y containing Y as the first additive component 2 o 3 , MnCO containing Mn as the second added component 3 , SiO containing Si as the third added component 2 .

[0097] And, with respect to 100 moles of the main component, weigh Y respectively 2...

Embodiment 2

[0119] Prepare BaCO 3 , CaCO 3 、TiO 2 , V 2 o 5 , Nb 2 o 5 、 Ta 2 o 5 、Cr 2 o 3 、MoO 3 and WO 3 , by approximately the same method and procedure as in [Example 1], the (Ba, Ca)(Ti, X)O of Examples 11 to 33 having the compounding molar ratio shown in Table 4 was prepared. 3 (X=at least one of V, Nb, Ta, Cr, Mo, and W) is the main component, and the X-ray spectrum of the main component is measured by XRD to measure the half-amplitude ΔH.

[0120] Then, prepare La as a rare earth oxide 2 o 3 , CeO 2 、Pr 5 o 11 、Nd 2 o 3 、Sm 2 o 3 、Eu 2 o 3 、Gd 2 o 3 , Tb 2 o 3 、Dy 2 o 3 、Ho 2 o 3 、Er 2 o 3 、Tm 2 o 3 , Yb 2 o 3 、Lu 2 o 3 and Y 2 o 3 , In addition, prepare MnO, NiO, Fe as metal oxides 2 o 3 , MgO, Al 2 o 3 , and then prepare SlO as a sintering aid 2 , Li 2 o 3 , B 2 o 3 、Dy 2 o 3 , MgO, SiO 2 , Li 2 o 3 Various additional components, each additional component is weighed by having the composition described in Table 2, thereafter ...

Embodiment 26

[0132]In Example 26, since the total amount of Dy and Y added as the first added component exceeds 6 moles and 4.0 moles with respect to 100 moles of the main component, the CR product is as low as 1255Ω·F at 25°C, and as low as 1255Ω·F at 125°C. As low as 3Ω·F, the insulation deteriorated, and 41 out of 100 failed products were produced in the high-temperature load test at 1000 hours, and all of them were defective products at 2000 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com