Theta-doped 4HSiC avalanche ultraviolet photoelectric detector and its production

A technology of electrical detectors and ultraviolet light, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as response time, quantum efficiency, and breakdown voltage that cannot reach optimal values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

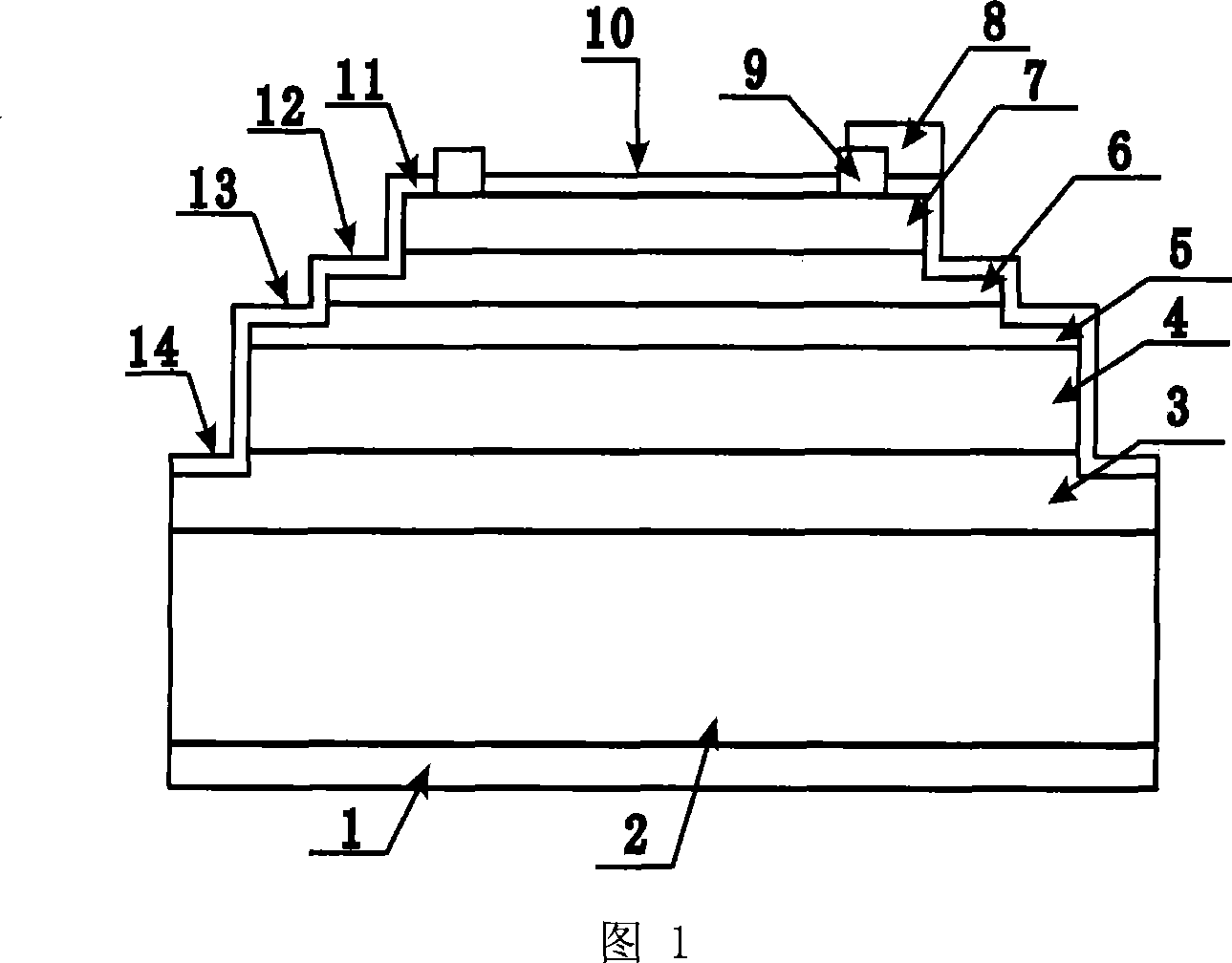

[0030] Referring to Fig. 1, the embodiment structure of the delta-doped 4H-SiC avalanche structure ultraviolet photodetector described in the present invention is: n + Type 4H-SiC substrate 2 and sequential epitaxial growth of heavily doped n + Type buffer layer 3, ultra-lightly doped n -- Type 4 (doping concentration lower than 1.0×10 15 / cm 3 , thickness 2.0 μm), δ-doped n-type layer 5 (doping concentration 3.0×10 17 / cm 3 , thickness 0.125μm), lightly doped n - Type layer 6 (doping concentration 6.0×10 15 / cm 3 , thickness 0.2μm) and heavily doped p + Type layer 7 (doping concentration 5.0×10 18 / cm 3 , with a thickness of 0.3 μm), a device isolation mesa 14, two terminal epitaxial mesas 12 and 13, an oxide layer 11, a p-type contact electrode 9, an n-type contact electrode 1, a pad 8, and a device photosensitive surface 10.

[0031] The example and preparation process of silicon carbide avalanche ultraviolet photodetector are described as follows:

[0032] 1. St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com