Double layer aluminum alloy composite sacrificial anode

A sacrificial anode and aluminum alloy technology, which is applied in the field of double-layer aluminum alloy composite sacrificial anode, can solve the problems of complex production and manufacturing process, no advantages of magnesium alloy anode, and small capacitance of magnesium alloy anode, so as to achieve simple production and manufacturing process , good protection effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

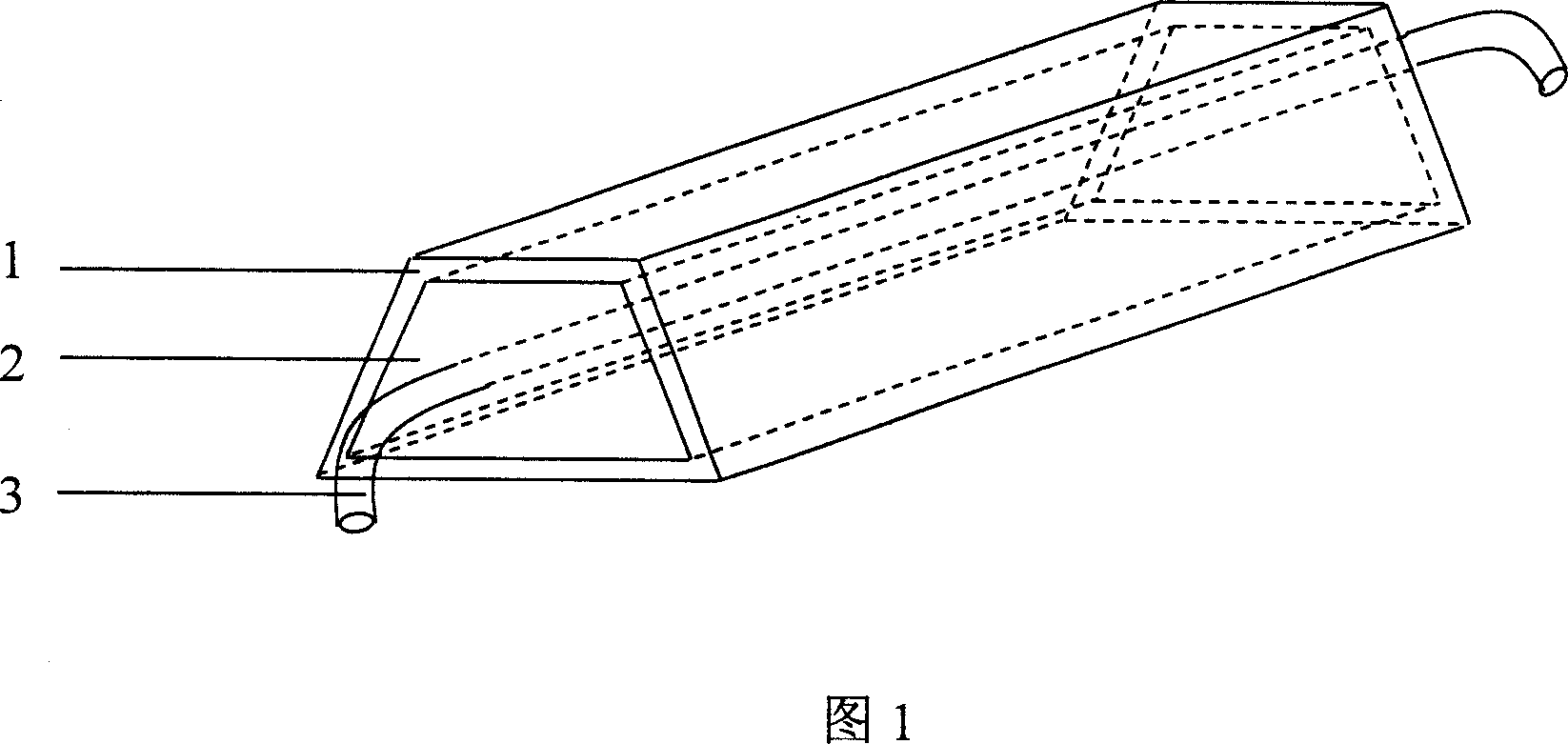

Image

Examples

Embodiment 1

[0020] According to the provisions of GB / T17848-1999, the electrochemical performance tests were carried out on the outer layer aluminum anode and the inner layer aluminum anode of the composite sacrificial anode sample. Wherein the composition of the outer layer is (by weight percentage): 3.0% zinc, 0.10% gallium, 0.022% indium, 0.012% tin, 0.01% bismuth, and the balance is aluminum; the inner layer composition is (by weight percentage): zinc 4.0 %, magnesium 1.0%, indium 0.022%, tin 0.02%, titanium 0.02%, and the balance is aluminum. The test results are: the working potential of the outer aluminum anode is -1.40--1.45V, and the current efficiency is about 50%; the working potential of the inner aluminum anode potential is -1.08--1.10V, and the current efficiency is about 90%. The composite sacrificial anode of the invention is composed of two different aluminum-based sacrificial anode materials, the inner and outer layers, and the inner and outer layers are closely combined...

Embodiment 2

[0031] In terms of weight percentage, the composition of the outer aluminum alloy of the sacrificial anode is: 3.5% zinc, 0.18% gallium, 0.022% indium, 0.01% tin, 0.03% bismuth, and the balance is aluminum; the inner layer aluminum of the sacrificial anode The composition of the alloy is: 3.0% zinc, 0.02% indium, 0.02% cadmium, 0.015% tin, 0.80% magnesium, 0.08% silicon, 0.04% titanium, and the balance is aluminum.

Embodiment 3

[0033] In terms of weight percentage, the composition of the outer aluminum alloy of the sacrificial anode is: 2.5% zinc, 0.06% gallium, 0.045% indium, 0.03% tin, 0.01% bismuth, and the balance is aluminum; the inner layer aluminum of the sacrificial anode The composition of the alloy is: 5.5% zinc, 0.04% indium, 0.01% cadmium, 0.05% silicon, and the balance is aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com