System and method for transforming low temperature residual heat into steam

A low-temperature waste heat and steam technology, applied in intersecting fields, can solve the problems of low thermal efficiency and low steam pressure, and achieve the effects of low equipment cost, simple process and high heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

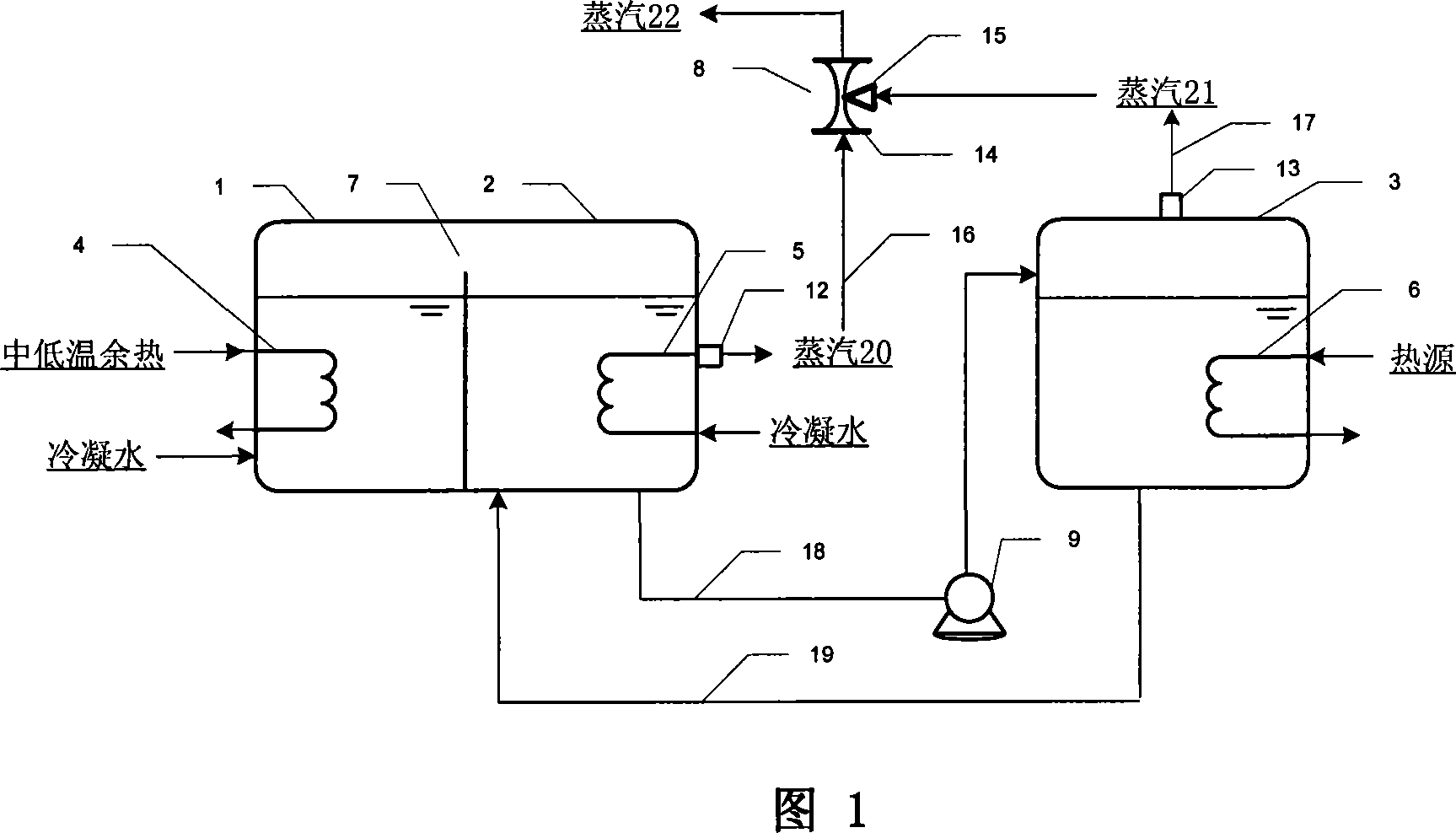

Embodiment 1

[0024] As shown in Figure 1, with the flue gas at about 500°C as the heat source of the generator 3, the absorption solution in the generator 3 is heated through the heat exchanger 6 placed in the generator 3 to evaporate and generate about 200°C, 0.2 MPa steam 21, while the concentration of the absorption solution in the generator 3 increases; the absorption solution of the generator 3 is introduced into the absorber 2. The absorption solution in the absorber 2 absorbs the steam from the evaporator 1 and generates absorption heat, heats the condensed water through the heat exchanger 5 placed in the absorber 2, makes it evaporate and generates steam 20 at about 150°C and 0.5 MPa, and at the same time The concentration of the absorption solution in the absorber 2 decreases. With the low-temperature flue gas at about 250°C as the heat source of the evaporator 1, the condensed water in the evaporator 1 is heated through the heat exchanger 4 placed in the evaporator 1 to evaporate...

Embodiment 2

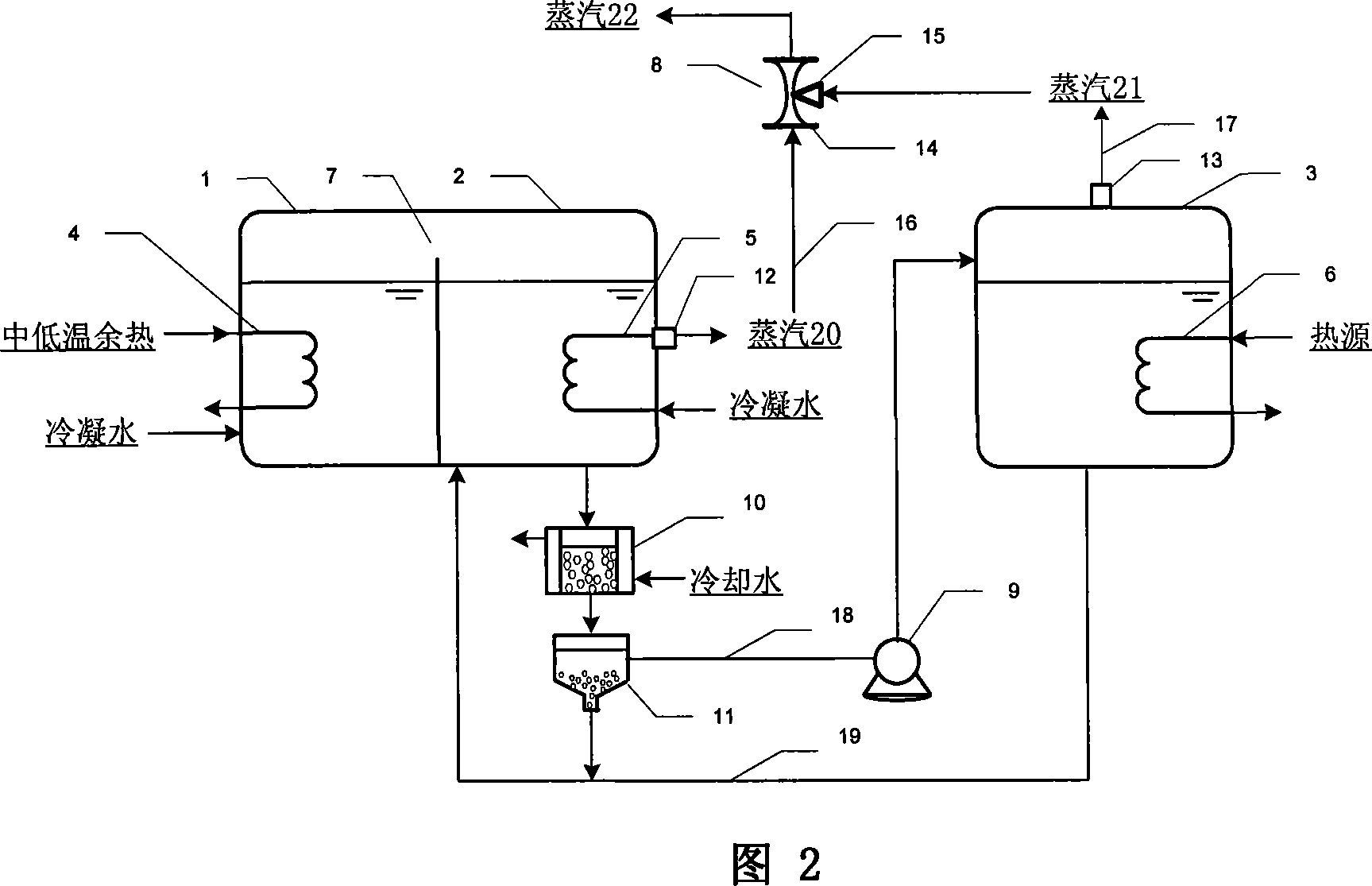

[0026]The first system of the present invention has the advantage of simple process, but has the disadvantage of low pressure of the produced steam. This is due to the mutual restriction of the working concentration of the absorber absorption solution and the working concentration of the generator absorption solution. In order to further increase the produced steam pressure, the second system of the present invention is shown in Fig. 2, and its process characteristic is that a cooling crystallizer 10 and a solid-liquid separator 11 are set between the absorber 2 and the generator 3. This embodiment is the same as the above-mentioned first embodiment, the low-temperature flue gas of about 250° C. is used as the heat source of the evaporator 1 , and the flue gas of about 500° C. is used as the heat source of the generator 3 . Steam at about 90°C is generated in the evaporator 1, and the steam enters the absorber 2 through the connecting channel 7; in the absorber 2, the absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com