Compound fabric capable of preventing diversiform harm factors roundly

A hazard factor and composite fabric technology, which is applied in multi-layer fabric systems, emergency rescue protection requirements, and the field of personal protective clothing, can solve the problems of protective performance against a single hazard factor and cannot meet emergency rescue protection requirements, etc., and achieve good water vapor permeability , good antibacterial performance and anti-biochemical toxin performance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

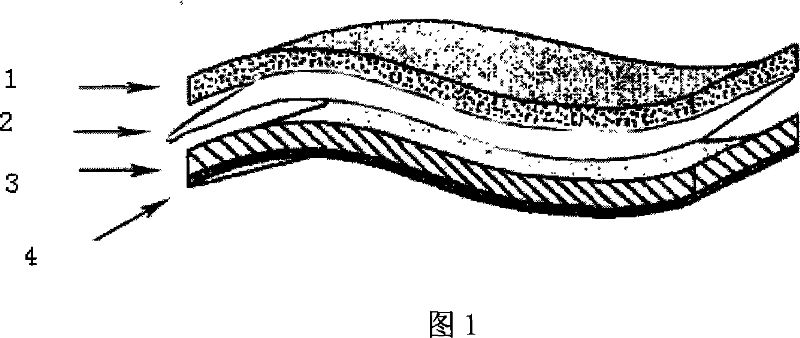

[0025] As shown in Figure 1: the multi-layer fabric system of the present invention includes a fireproof outer layer 1, a waterproof, moisture-permeable, anti-chemical and anti-virus layer 2, a heat-insulating layer 3, and a comfortable layer 4 arranged sequentially from the outside and the inside, and the waterproof and moisture-permeable The anti-chemical and anti-virus layer 2, the heat insulation layer 3, and the comfort layer 4 are combined by quilting with sewing threads.

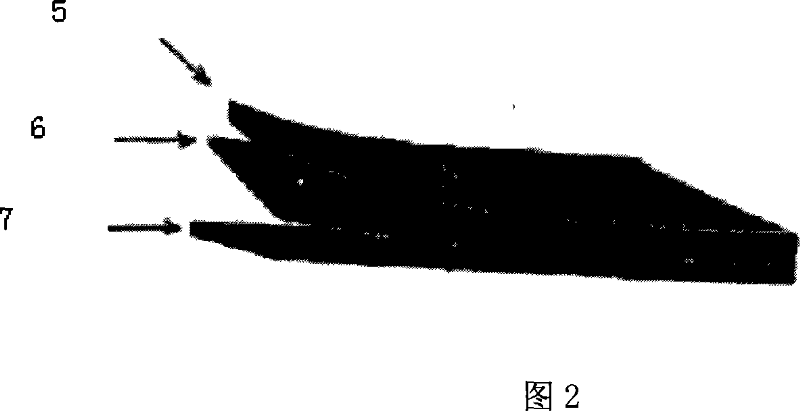

[0026] As shown in Figure 2: the waterproof, moisture-permeable, anti-chemical and anti-virus layer of the present invention comprises a flame-retardant antibacterial cotton cloth 5, a PTFE film 6, and an activated carbon felt 7 arranged sequentially from the outside and the inside, and the described flame-retardant antibacterial cotton cloth 5, selective The permeable membrane 6 and the activated carbon felt 7 are compounded through a lamination process. The materials used in the above-mentioned mult...

Embodiment 2

[0028] Fire-resistant outer layer: PBI / Kevlar flame-retardant fiber blended fabric.

[0029] Waterproof, moisture-permeable, chemical-proof and anti-virus layer: flame-retardant antibacterial cotton cloth, PTFE film, viscose-based activated carbon felt with a thickness of 1.3mm "three-in-one" laminated composite material.

[0030] Insulation: 100% Aramid 1313 insulation felt.

[0031] Comfort Layer: Flame Retardant Cotton.

[0032] Example 2:

[0033] Fire-resistant outer layer: flame-retardant fabric with Nomex IIIA as the main component.

[0034] Waterproof, moisture-permeable, chemical-proof and anti-virus layer: flame-retardant antibacterial cotton cloth, PTFE film, viscose-based activated carbon felt with a thickness of 1.3mm "three-in-one" laminated composite material.

[0035] Insulation: 50% Nomex50% Kevlar insulation felt.

[0036] Comfort Layer: Flame Retardant Cotton.

Embodiment 3

[0038] Fireproof outer layer: polysulfone fiber flame-retardant fabric.

[0039] Waterproof, moisture-permeable, chemical-proof and anti-virus layer: flame-retardant antibacterial cotton cloth, PTFE film, viscose-based activated carbon felt with a thickness of 1.0mm "three-in-one" laminated composite material.

[0040] Insulation: 100% Nomex insulation felt.

[0041] Comfort Layer: Flame Retardant Cotton.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com