Modified apparatus and method for preparing 35 percent hydrogen peroxide by using hydrogen with low purity of 90 percent

A hydrogen peroxide, low-purity technology used in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, etc. It can solve the problems of short service life and low purity of palladium catalyst, and achieve the effect of long service life, optimized process conditions and improved economic benefits.

Inactive Publication Date: 2007-09-19

黑龙江黑化集团有限公司

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, hydrogen peroxide is produced by using a large amount of residual hydrogen from synthetic ammonia or urea plants. Because the purity of hydrogen is 90-92%, the average hydrogenation efficiency is 6.35g / l, while the average oxidation efficiency is 5.7g / l, and the raffinate is 0.3 About g / l, can only produce the hydrogen peroxide of 27.5% concentration, the service life of palladium catalyst is shorter, how to utilize existing condition (H 2 Purity is low) the existing device produces 35% concentration hydrogen peroxide, satisfies market demand, transformation is imperative

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0029] Embodiment 2 is basically the same as the equipment structure and process conditions of Embodiment 1, and the production steps are the same, and the scale is a kiloton level. The results are as follows

[0030] hydrogen

[0031] 90%

[0032] hydrogen

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

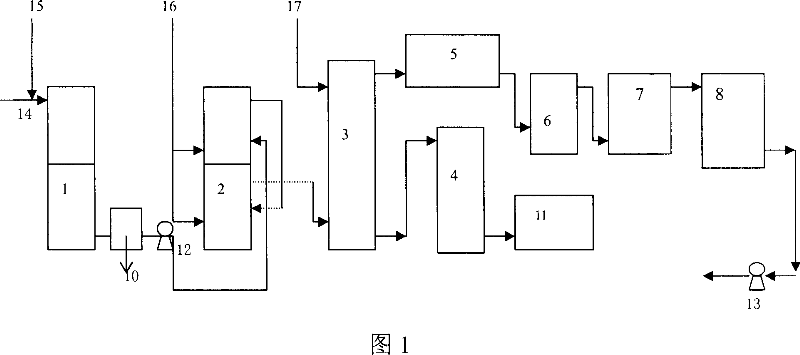

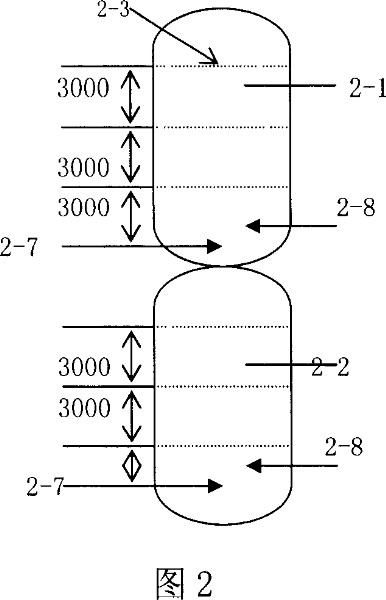

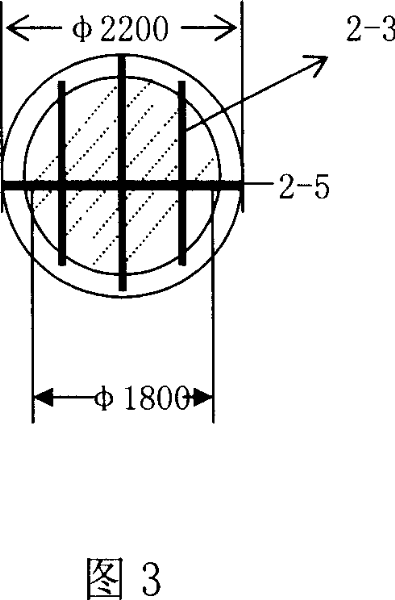

The present invention relates to an improved device and method for preparing hydrogen peroxide having a concentrate of 35% by low purity hydrogen gas having a concentrate of 90%, which is characterized in that the empty oxidation tower is changed into a sieve plate column provided with 2~5 distribution boards therein, wherein the distribution board comprises four pieces of dismounting type small sieve plates and is fixed on the intermediate beam, and sieve pores having a diameter of 3~10 mm and a percentage of open area of 30~40% are equably arranged on the distribution board in a prismatic array; each sieve plate is provided with 4~6 downcomers in the extraction column in prior art, which is changed into that each of the upper fourteen sieve plates is provided with one downcomer while each of the lower forty sieve plates is provided with two downcomers, and the topside of the column is filled with 1500~2000 mm ripple packing, and the distance between the packing and the topside sieve plate is 400 mm, and the process conditions are optimized so that the oxidation efficiency is improved from 5.7 g / l to 6.1~6.3 g / l, the oxidation yield is more than 95%, the surplus extraction rate is decreased from 0.3 g / l to0.1 g / l, the device can be used for directly producing H2O2 with a concentration of 35% from residual source of hydrogen of the 95% low purity synthetic ammonia or urea device. The device and the technology method are adapted to the hydrogen peroxide device of the present matching synthetic ammonia or urea device to produce H2O2 with a concentration of 35%.

Description

technical field [0001] The invention relates to the field of chemical engineering, in particular to an improved device and method for producing 35% hydrogen peroxide with 90% low-purity hydrogen. Background technique [0002] At present, the production of hydrogen peroxide by the anthraquinone method generally adopts a fixed-bed reactor. Hydrogen peroxide, the working fluid is recycled. The requirement for raw material hydrogen in the production is very high, because palladium catalyst is used in the production of hydrogen peroxide, and the operating conditions of palladium catalyst are relatively harsh, if the material contains SO 2 , CO, NH 3 If the impurities exceed the standard, the catalyst will be poisoned. Usually the production device uses pure hydrogen source, purity ≥ 98%, N 2 Content ≤ 1.6%, in order to have a high hydrogenation efficiency, in order to produce products with a concentration of 35% hydrogen peroxide, H 2 The lower the purity, the lower the hydr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B15/022C01B15/023B01J23/44

Inventor 阎树忠朱勋绩张学发岳守成郑青吾栾友于洪艳杨洪政张玉石潘为森

Owner 黑龙江黑化集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com