Environmental protection type waste tyre electrical cracking technique and equipment

An environmentally friendly technology for waste tires, which is applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and fibrous fillers. It can solve the problems of secondary pollution, many processing links, and long production processes, and reduce heat loss. Compact, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

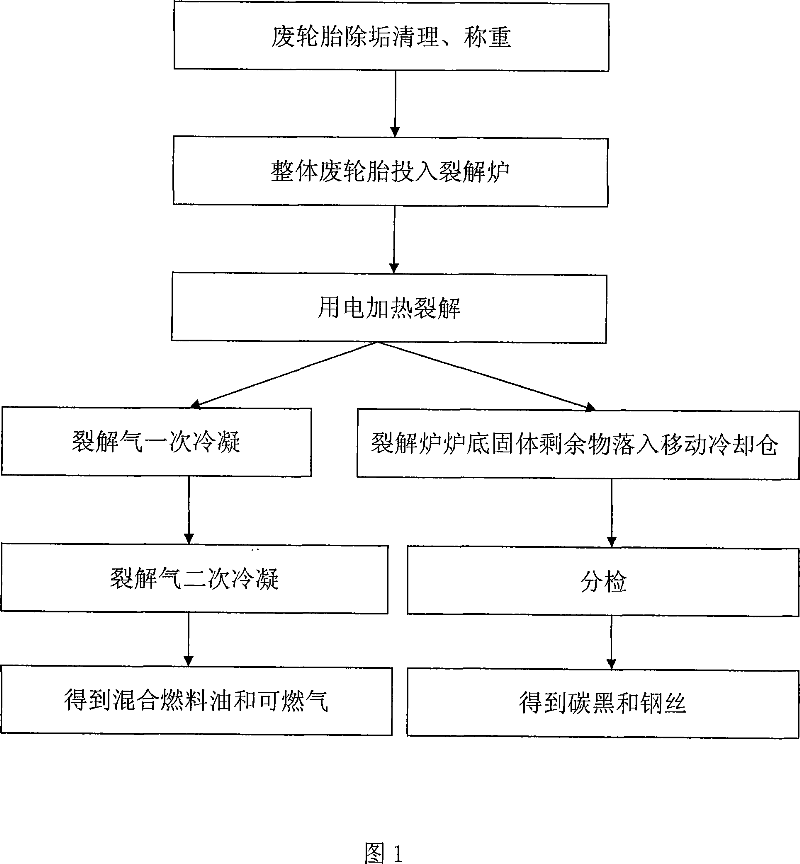

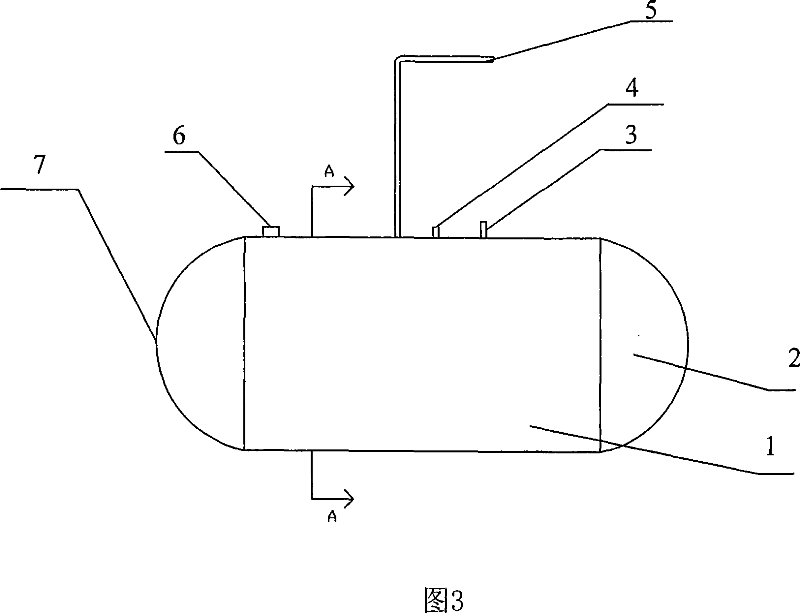

[0024] Embodiment 1, as shown in Figures 1, 2, and 3, the feed port (7) of the pyrolysis furnace body of furnace (1) is opened, and 100 kg of integral waste tires that do not need to be broken or cut off after cleaning and descaling are dropped into the pyrolysis furnace , close the feed inlet (7), turn on the power supply to increase the temperature in the cracking furnace, detect the temperature in the furnace through the thermocouple (4) probe, and transmit the temperature information in the furnace to the control cabinet. Control the heater to let the waste tires in the pyrolysis furnace react at 250°C-350°C for 60 minutes. The waste tires are cracked to generate a large amount of pyrolysis gas, which enters the condenser through the exhaust pipe (5) on the pyrolysis furnace body for cooling Separate, obtain combustible gas and mixed oil by twice condensation, after turning off the power supply, open the discharge port (2) of the furnace body of the cracking furnace, the re...

Embodiment 2

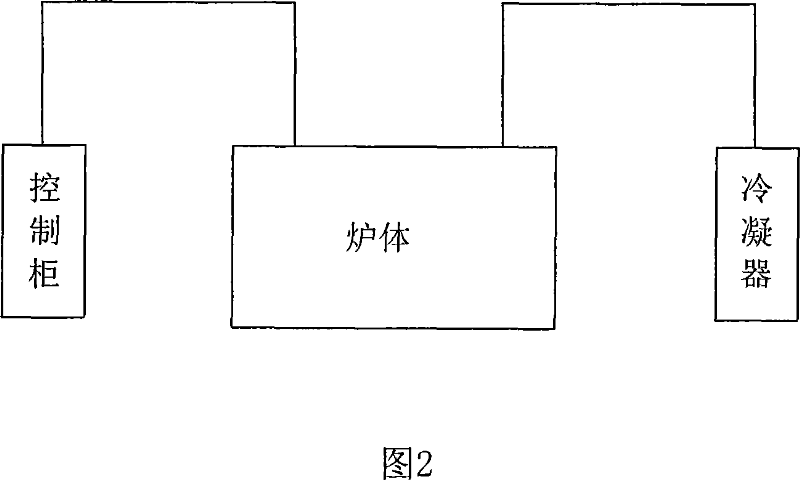

[0025] Embodiment 2, as shown in Figures 2, 3, and 4, the environmentally friendly waste tire electric energy cracking equipment includes a cracking furnace, a condenser and a control cabinet, and the cracking furnace and the condenser are connected by an exhaust pipe (5). Even (4) is connected with the control cabinet by cables, and the heater (1-3) in the cracking furnace is connected with the control cabinet by a power supply control line; the cracking furnace mainly includes a cracking furnace body (1), a cracking furnace body (1 ) has a feed inlet (7) at one end, and a discharge outlet (2) at the other end, adopting a hydraulic pressure opening and sealing device, and an exhaust pipe (5), a safety explosion-proof device (3), The power connection terminal (6) and the thermocouple (4), the probe of the thermocouple (4) is inserted into the innermost layer of the cracking furnace body (1) to measure the temperature in the furnace body; the furnace wall of the cracking furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com