A pyrolysis treatment device and method for radioactive waste resin

A technology of radioactive waste resin and treatment method, which is applied in the fields of radioactive purification, nuclear engineering, products, etc., can solve the problems of high energy consumption of incineration method, increased volume of waste resin, and easy cracking of solidified body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Under a nitrogen atmosphere, use a thermogravimetric analyzer TG to carry out thermogravimetric analysis of the radioactive waste 717 type anion exchange resin, and its thermogravimetric temperature is T 1 =78.9°C, T 2 =299.6°C, T 3 =403.8°C.

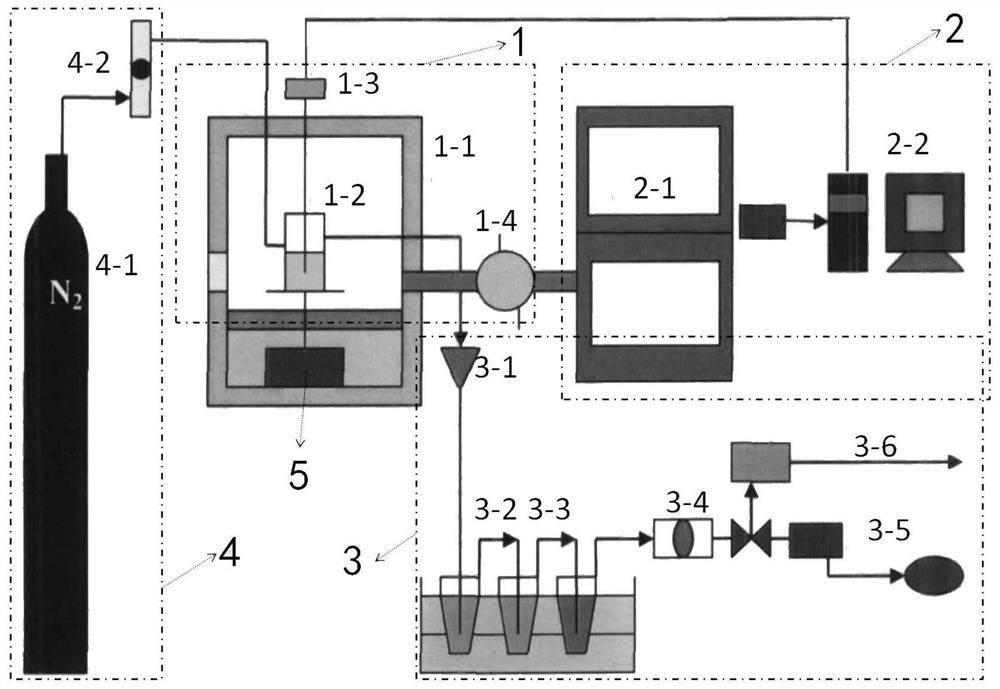

[0069] (2) The radioactive waste 717 type anion exchange resin of 0.5kg is placed in the waste resin container 1-2 of the pyrolysis treatment device of radioactive waste resin, open nitrogen input system 4 and microwave generation and control system 2, when nitrogen flow rate is In a nitrogen atmosphere of 30mL / min, the temperature is raised to 78.9°C at a rate of 10°C / min, the microwave power is 5kW, the frequency is 2.45GHZ, and the temperature is maintained for 0.5h. The pyrolysis gas enters the pyrolysis gas treatment system 3 and passes through the filter 3-1( Nuclear-grade high-efficiency filter, filter material is inorganic glass fiber), gas scrubber 3-2 (gas scrubbing liquid is 0.1mol / L sodium hydroxide solution), c...

Embodiment 2

[0074] (1) Under a nitrogen atmosphere, use a thermogravimetric analyzer TG to carry out a thermogravimetric analysis of the radioactive waste 201×7 type strongly basic anion exchange resin, and its thermogravimetric temperature is T 1 =107.8°C, T 2 =203.6°C, T 3 =411.2°C.

[0075] (2) The radioactive waste 717 type anion exchange resin of 0.5kg is placed in the waste resin container 1-2 of the pyrolysis treatment device of radioactive waste resin, open nitrogen input system 4 and microwave generation and control system 2, when nitrogen flow rate is In a nitrogen atmosphere of 20mL / min, the temperature is raised to 107.8°C at a rate of 10°C / min, the microwave power is 5kW, the frequency is 2.45GHZ, the temperature is maintained for 0.5h, the resin quality is reduced to 55%, and the pyrolysis gas enters the pyrolysis gas treatment system 3, Condensed to After room temperature and desiccator 3-4, enter the gas collection tank 3-5 for storage, and use the gas analyzer 3-6 to a...

Embodiment 3

[0081] (1) Under a nitrogen atmosphere, use a thermogravimetric analyzer TG to carry out thermogravimetric analysis of the radioactive waste 732 type cation exchange resin, and its thermogravimetric temperature is T 1 =110.4°C, T 2 =426.2°C.

[0082] (2) Place 1 kg of radioactive waste 732 type cation exchange resin in the waste resin container 1-2 of the pyrolysis treatment device for radioactive waste resin, open the nitrogen input system 4 and the microwave generation and control system 2, and set the nitrogen flow rate at 30mL / min in a nitrogen atmosphere, the temperature is raised to 110.4°C at a rate of 15°C / min, the microwave power is 10kW, the frequency is 2.45GHZ, and the temperature is maintained for 0.5h. The pyrolysis gas enters the pyrolysis gas treatment system 3 and passes through the filter 3-1 (nuclear high-efficiency filter, the filter material is inorganic glass fiber), gas scrubber 3-2 (gas scrubbing liquid is 0.1mol / L sodium hydroxide solution), condense...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com