Crude oil pulsing electrical desalting technique

A pulsed electric and secondary electric desalination technology, which is applied in the direction of electricity use/magnetic dehydration/demulsification, etc., can solve the problems of poor desalination effect, no technical process and process conditions of crude oil electric desalination, and high power consumption, so as to save electric energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

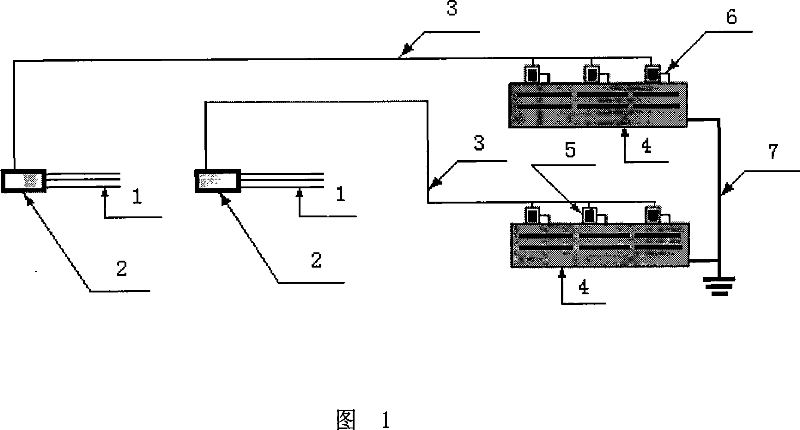

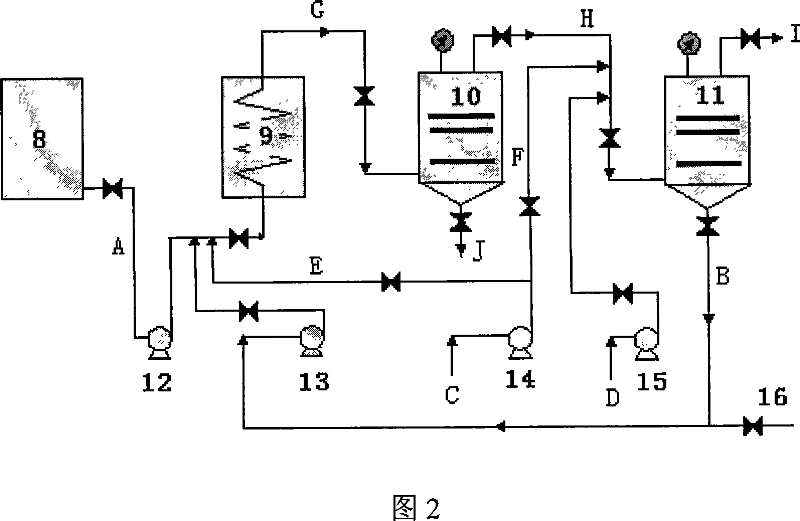

[0025] In this embodiment, on the basis of the existing electric desalination tank and its auxiliary facilities, the full-impedance transformer and its control system of the conventional electric desalination are replaced by a pulse transformer and its control system. The pulse power supply consists of a pulse generation controller 2 and a full-impedance high-frequency explosion-proof transformer 5 , the pulse generation controller 2 is installed in the operating room, and the high-frequency explosion-proof transformer 5 is installed on the electric desalination tank 4 . The input 380V power frequency power supply 1 is rectified and inverted by the pulse generator controller to become the required pulse signal, and then transmitted to the high-frequency explosion-proof transformer placed on the electric desalination tank through the cable 3, after boosting to the voltage required by the electric desalination process, The high-voltage cable 6 is connected to the inner pole plate...

Embodiment 2

[0029] The production equipment and technological process that present embodiment adopts are the same as embodiment 1.

[0030] Its crude oil density is 878.2Kg / m 3 , the salt content is 98.5mgNaCl / l; the desalination temperature is 120°C; the demulsifier is oil-soluble, the model is EC2425A; the water injection is industrial purified water, PH=6.0.

[0031] The addition amount of primary desalination demulsifier is 5 μg / g, the water injection volume is 5%, the pulse electric field strength in the strong field area is 2000V / cm, the pulse frequency is 1000Hz, and the duty cycle is 30%; the secondary desalination water injection volume is 5%, The pulse electric field strength in the strong field area is 2000V / cm, the pulse frequency is 1000Hz, and the duty cycle is 30%.

[0032] Salt content after removal / mgNaCl·l -1

Embodiment 3

[0034] The production equipment and technological process that present embodiment adopts are the same as embodiment 1.

[0035] Its crude oil density is 878.2Kg / m 3 , the salt content is 98.5mgNaCl / l; the desalination temperature is 135°C; the demulsifier is oil-soluble, the model is EC2425A; the water injection is industrial purified water, PH=8.0.

[0036] Salt content after removal / mgNaCl·l -1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com