Pipeline of polar polymer and poleless polymer composing with metal reinforcement

A composite pipe and metal reinforcement technology, applied to rigid pipes, pipes, pipes/pipe joints/pipe fittings, etc., can solve problems such as difficult bonding and compounding, and achieve reliable pipe network performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

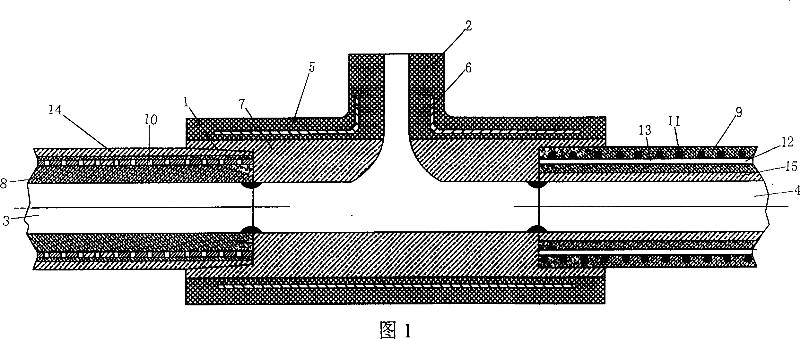

[0028] Fig. 1 has provided the figure of embodiment 1 of the present invention. Referring to Fig. 1, a φ160mm composite pipe network 1 composed of polar polymers and nonpolar polymers and a metal reinforcement skeleton is composed of three-way pipe fittings 2 and pipes 3 and 4. The pipe wall of the pipe fitting 2 is formed by bonding and coating the inner and outer surfaces of the graft-modified polyolefin continuum 5 with polar groups passing through the holes in the steel reinforcement skeleton 6 with holes. , a layer of non-polar polyolefin layer 7 is compounded on the surface of the inner layer of the pipe wall. The pipe walls of the pipes 3 and 4 are made of graft-modified polyolefin continuums 8 and 9 respectively passing through steel plates with holes and welded cylindrical skeletons 10 or latitudinal steel wires 11 wound radially. The steel wires 12 are welded to form a cylindrical frame 13 and are respectively bonded and clad with the cylindrical frame. A non-polar...

Embodiment 2

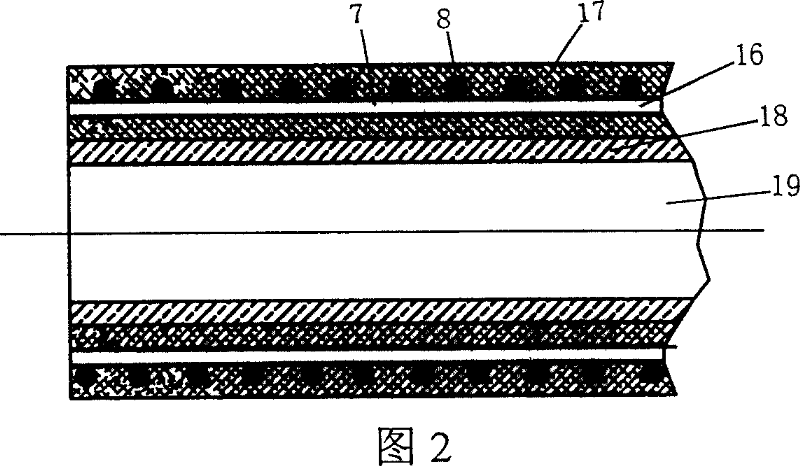

[0031]Fig. 2 shows a schematic diagram of the pipe structure in Example 2 of the present invention. Referring to Fig. 2, the structure of the skeleton 16 in the pipe 19 is the same as that of the cylindrical skeleton in Example 1, both are cylindrical skeletons welded by steel wire mesh, and the pipe wall is formed by firmly bonding and covering the skeleton through the holes on the cylindrical skeleton The continuum of 17 is non-cross-linked temperature-resistant polyethylene (PE-RT) with polar groups (PE-RT DX800 produced by SK Company in Korea). The warm polyethylene grafting rate is 0.5%-0.8%, 100 parts by mass, 2-5 parts of maleic anhydride (MAH), and 0.1-0.4 parts of peroxide grafting initiator (DCP). The inner layer of the pipe wall 17 is compounded with a non-polar non-crosslinked heat-resistant polyethylene layer 18. The pipe 13 is connected with pipe fittings of the same structure to form a pipe network, which can withstand hot water at 60-80°C for long-term safe ope...

Embodiment 3

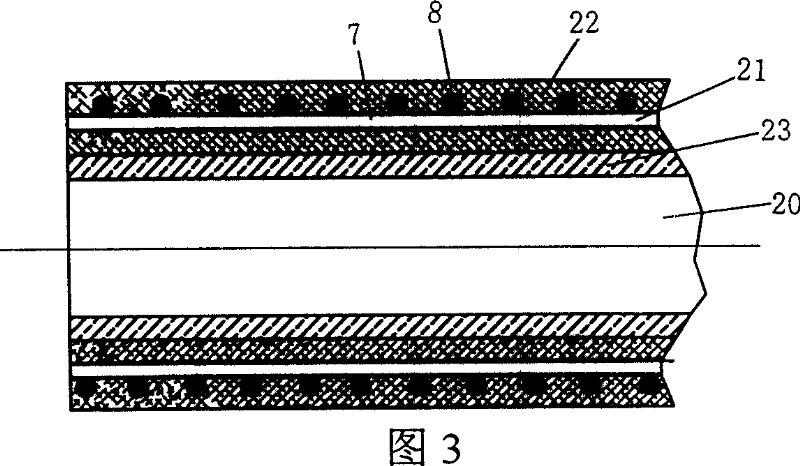

[0033] Fig. 3 shows a schematic diagram of the pipe structure in Example 3 of the present invention. Referring to Fig. 3, in the pipe 20, there is a tubular metal reinforcement skeleton 21 formed by winding radial steel wires and welding the latitudinal steel wires, and the continuum of the pipe wall 22 formed by firmly bonding and covering the metal skeleton through holes has polar groups random copolymerized polypropylene, and the inner layer of the pipe wall 22 is compounded with a random copolymerized polypropylene (PP-R) layer 23 without polarity. Extrude and granulate with an extruder according to the following formula to obtain a polypropylene with a polar group with a graft rate of 0.4% to 0.7%. This polypropylene can be used to produce composite pipes for hot water pipe networks. At 80°C, 0.6Mpa long-term operation under conditions. The formula is: 100 parts of random copolymerized polypropylene (PP-R) produced by Beijing Yanshan Petrochemical Co., Ltd. 2-4 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com