Orientation clamping board of the automatic welding equipment with a big elbow

A technology of automatic welding and processing methods, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of automatic welding difficulties, positioning jams and other problems that have not been found, and achieve a simple structure, simple and easy production method , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

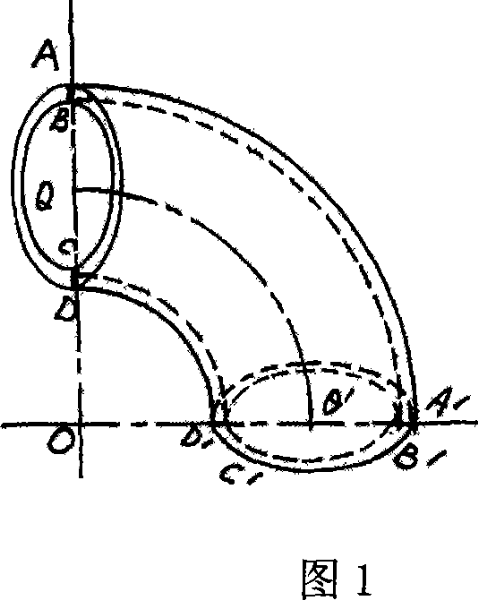

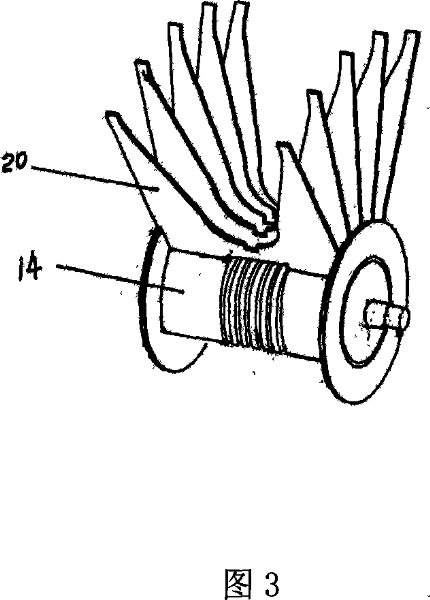

[0031] The large elbow positioning device, as shown in Figure 3, includes several clamping plates 20 fixed on the drum 14. The large elbow positioning device has the functions of automatic centering and welding seam alignment. The clamping plates of the positioning device are shown in the figure 5, including the bottom 201, the left wing 202, and the right wing 203, the whole is V-shaped, the left wing and the right wing are symmetrical, the circle specified between any symmetrical points inside the two wings of the clamping plate and the cross section of the large elbow clamped at these two points Coincidentally, as shown in Figure 1, the cross section of the large elbow is the circle AD with Q as the center. The card plate includes small arcs NH and N'H', two circular cut surfaces HI and H'I', large arcs JI and J'I', and stoppers KJ and K'J' from the bottom to the top , there is a groove NPP'N' at the lower part of the small arc, and a groove STT'S' in the middle below the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com