Acid-washing waste acid reproduction method

A technology of pickling waste acid and pickling steel, which is applied in the field of recovery of pickling waste acid, can solve problems such as environmental pollution and waste of resources, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

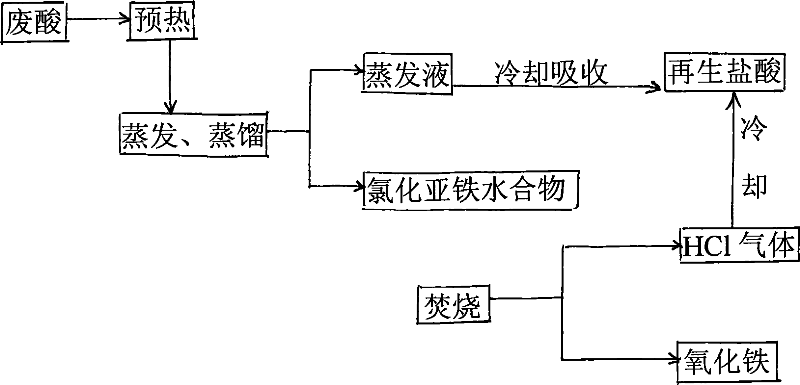

[0010] A method for regenerating waste pickling acid, comprising the following steps: preheating waste hydrochloric acid solution at 75 to 85°C after pickling steel product surface rust, and distilling the hydrochloric acid out of it through evaporation and distillation, and heating the waste hydrochloric acid solution at 45°C Cooling and recovery; at the same time, incinerate the ferrous chloride hydrate formed after evaporation, the incineration temperature is 370-390 ℃, the hydrogen chloride gas produced by incineration is recovered as hydrochloric acid after cooling, and the iron oxide produced by incineration is collected.

[0011] The chemical principle of the present invention is: when hydrochloric acid washes and removes the rust on the surface of steel products, iron oxide and hydrochloric acid react to generate ferrous chloride and low-concentration hydrochloric acid, that is:

[0012] Fe 2 o 3 +HCl→FeCl 3 +H 2 o

[0013] FeCl 3 +Fe→FeCl 2

[0014] When incine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com