Recoverying method for sulfate in high concentration acid-containg waste liquid of battery factory

A battery factory and recovery method technology, applied in separation methods, chemical instruments and methods, water pollutants, etc., can solve problems such as unusable sulfuric acid, low sulfuric acid recovery rate, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

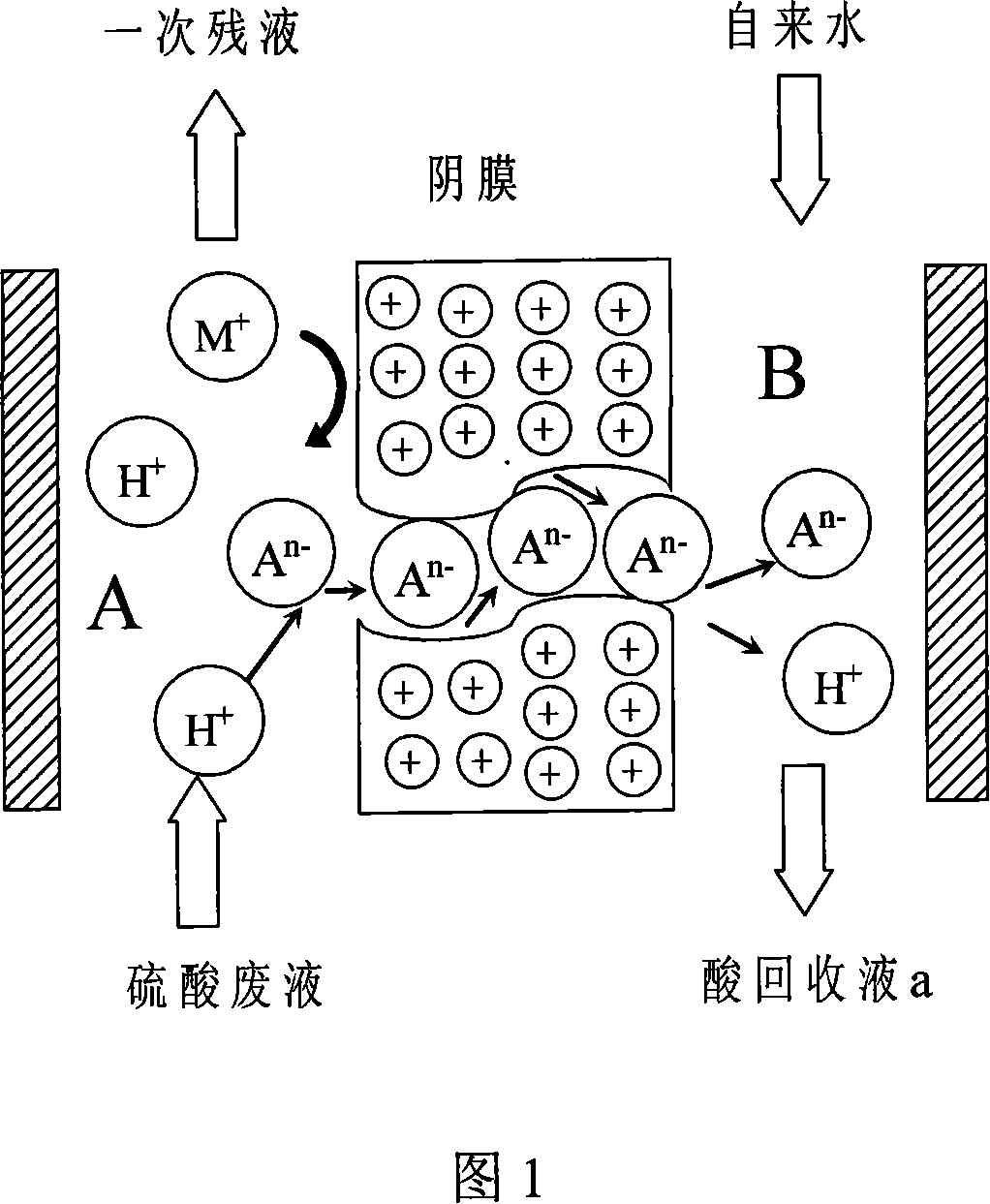

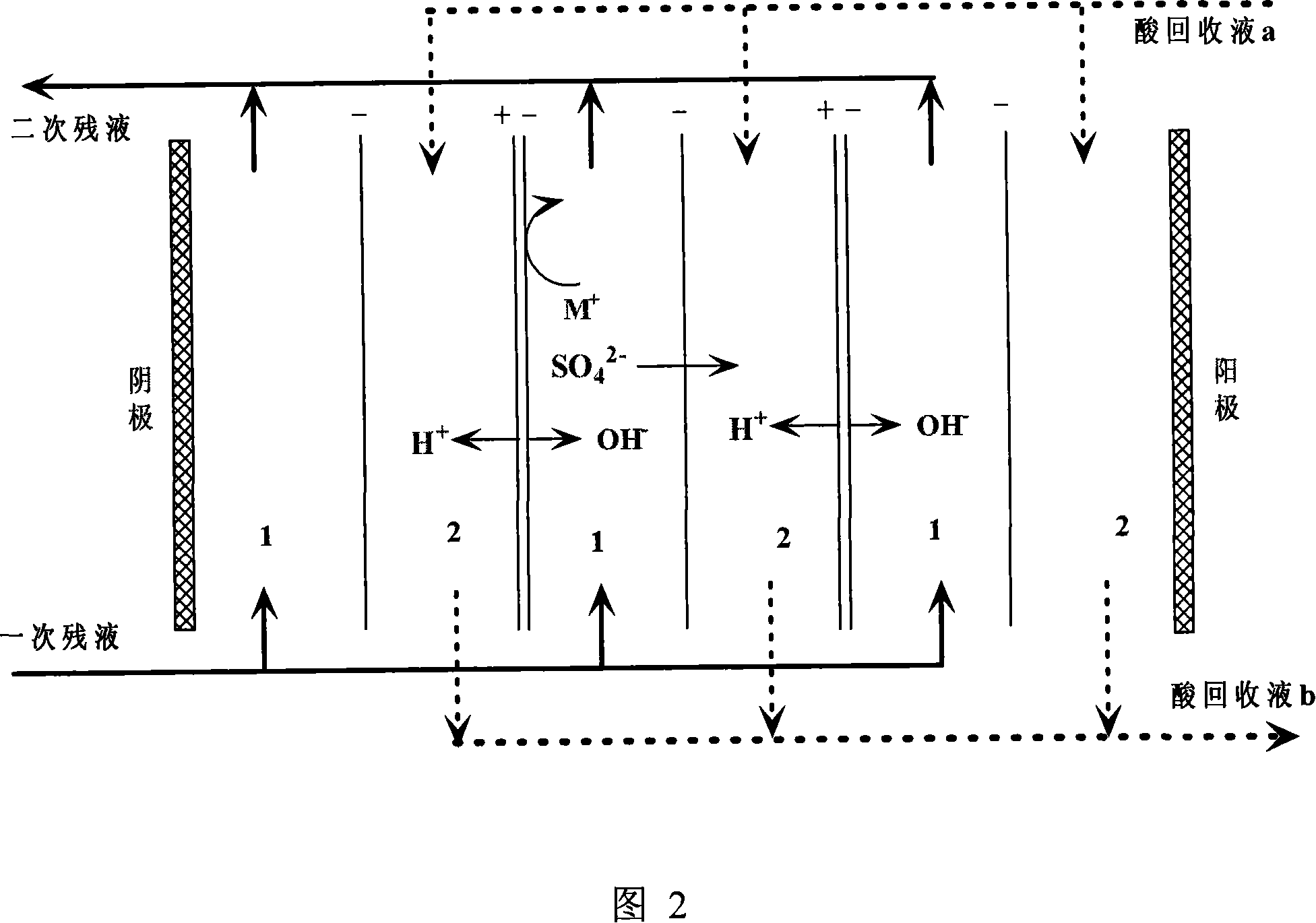

[0021] Specific embodiment one: the steps of the method for reclaiming sulfuric acid in this embodiment are as follows: a, first carry out diffusion dialysis to the sulfuric acid waste liquid in the battery production, and recycle under the condition that the ratio of waste acid to tap water volume is 1:1~1:3 Most of the sulfuric acid; b. The primary raffinate treated in step a is subjected to bipolar membrane electrodialysis, and the electrodialysis is carried out at a voltage of 8 to 15V for 90 to 200 minutes to recover sulfuric acid. The concentration of sulfuric acid in the secondary raffinate after sulfuric acid recovery is 0.04 %~0.12%, the ferrous ion concentration is 14.40mg / L, and the lead ion concentration is 2.94mg / L, which can be discharged after neutralization; c, mix the sulfuric acid recovered through step a and step b with commercially available chemically pure Concentrated sulfuric acid is mixed and formulated into a 10% to 15% sulfuric acid solution, which mee...

specific Embodiment approach 2

[0023] Embodiment 2: In this embodiment, the diffusion dialysis in step a adopts a homogeneous anion exchange membrane. Others are the same as in the first embodiment.

[0024] The homogeneous anion exchange membrane used in this embodiment has a chemically cross-linked structure. Since the homogeneous anion exchange membrane has stronger repellency to metal cations than the heterogeneous anion exchange membrane, the exchange capacity for anions is also larger.

specific Embodiment approach 3

[0025] Embodiment 3: The homogeneous anion exchange membrane of this embodiment has a strong basic fixing group connected to the polymer skeleton. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com