Preparation of moisture controllable polymer composite film and its application

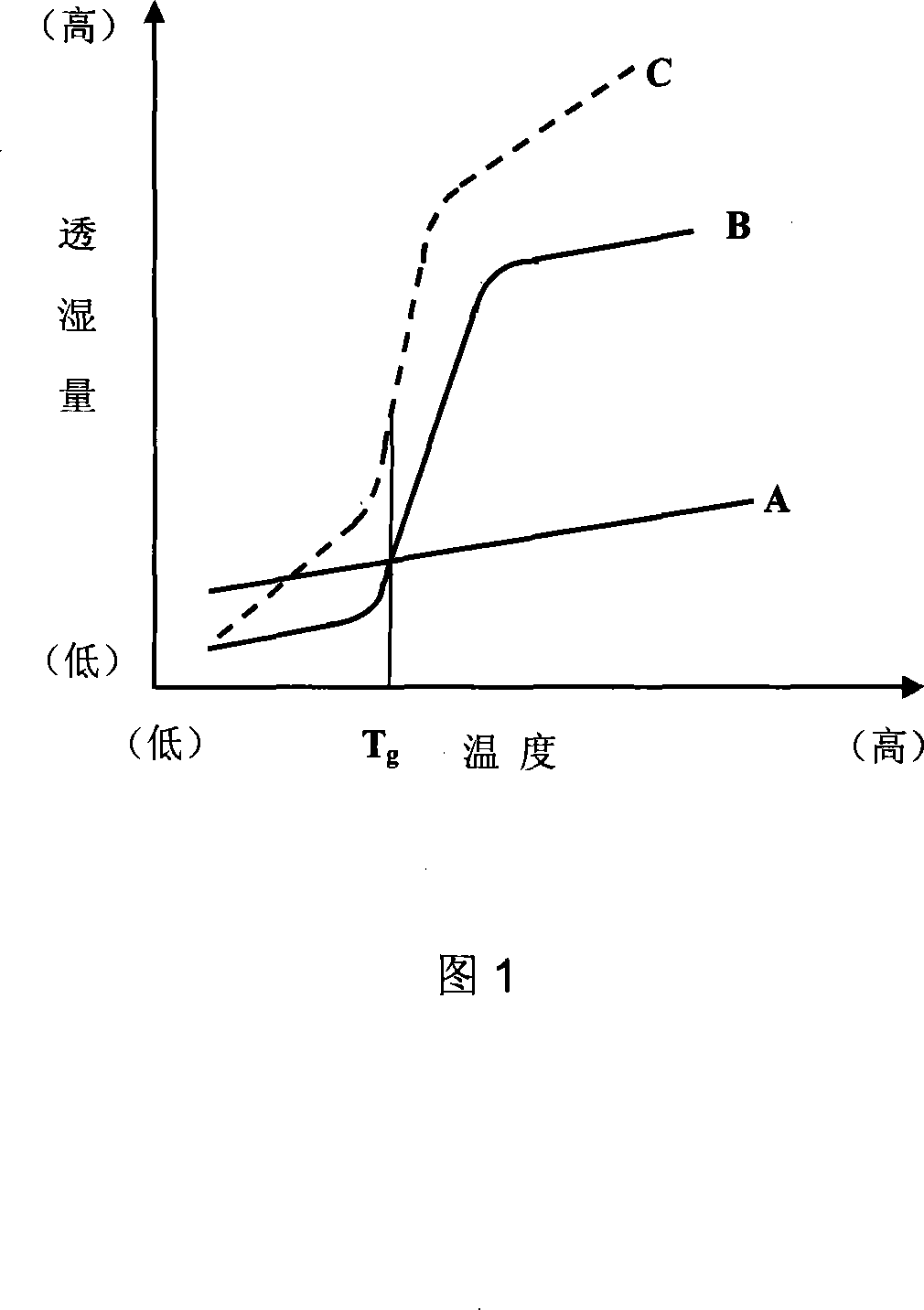

A technology of composite film and polymer is applied in the field of preparation of moisture permeable and controllable polymer composite film to achieve the effects of reasonable function, simple production and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037]In the polymer composite film prepared by the physical mixing method of the present invention, the trigger temperatures of the prepared hydrophilic shape memory polyurethane and poly(N-isopropylacrylamide) hydrogel systems are both set at 32°C. The prepared poly(N-isopropylacrylamide) hydrogel is in the state of moisture absorption and swelling, and is pulverized into tiny particles through a ball mill, and its average particle size distribution is between 450 and 550 nm, and is added to the 5wt.% water-based polyurethane dilution solution, stirred with a magnetic stirrer for 8 minutes to make it fully mixed, then poured into the template, evaporated water slowly at a low temperature at 20°C, and stood still to form a film. The thickness of the film is 35μm, and the square meter weight is 20g / m 2 , and its moisture permeability effect is shown in the table below.

[0038] polymer composite film

(film thickness) / (square meter weight)

(0.035mm) / (20g / ...

example 2

[0042] polymer composite film

example 3

[0044] polymer composite film

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com