Blowby gas ventilator and crankcase emission control system of internal combustion engine

A technology of blow-by gas and control system, which is applied in the field of blow-by gas ventilator and crankcase emission control system, which can solve the problems of decreased productivity, unsmooth flow of blow-by gas and complicated passage of blow-by gas and other issues, to reduce weight, maintain injection efficiency, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

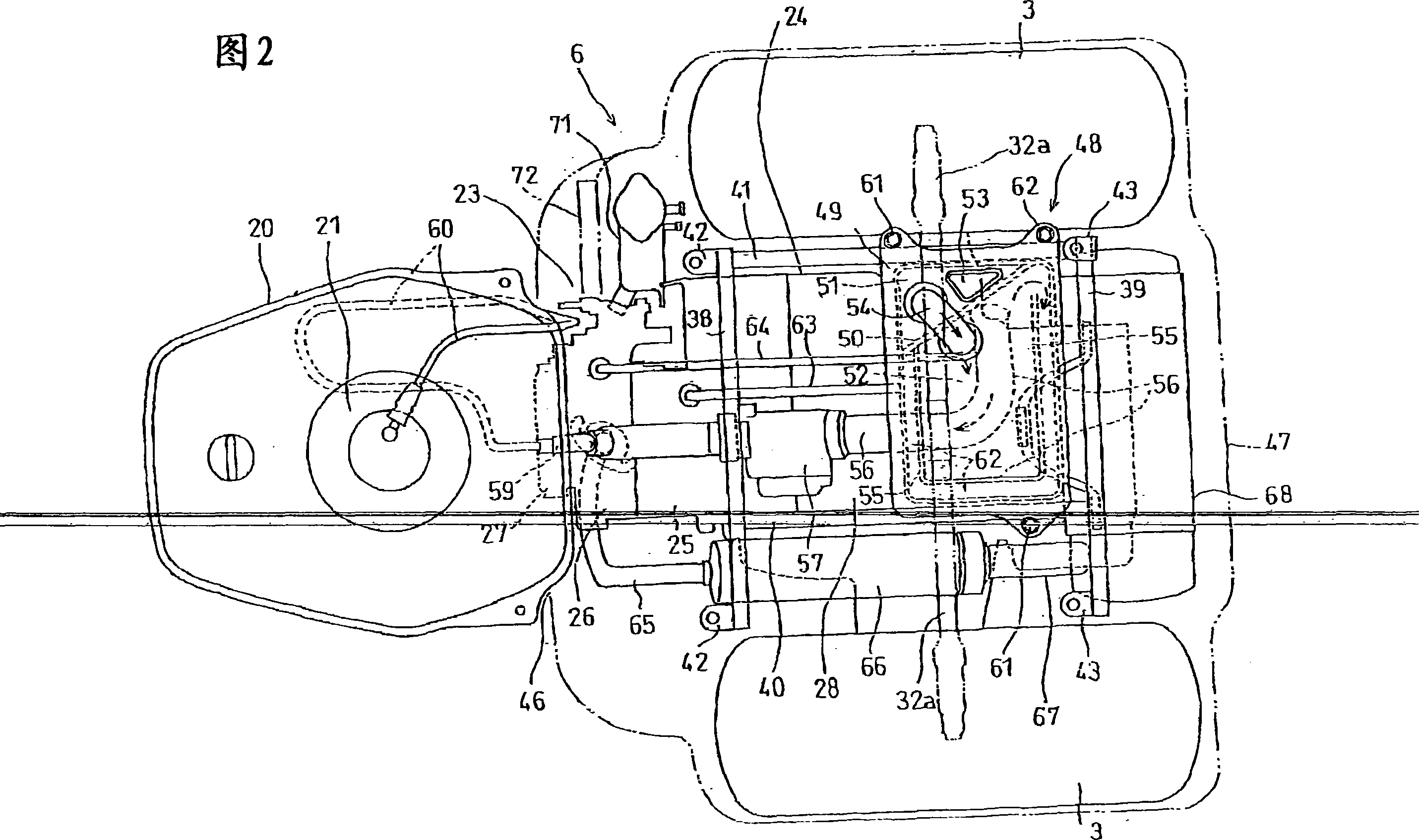

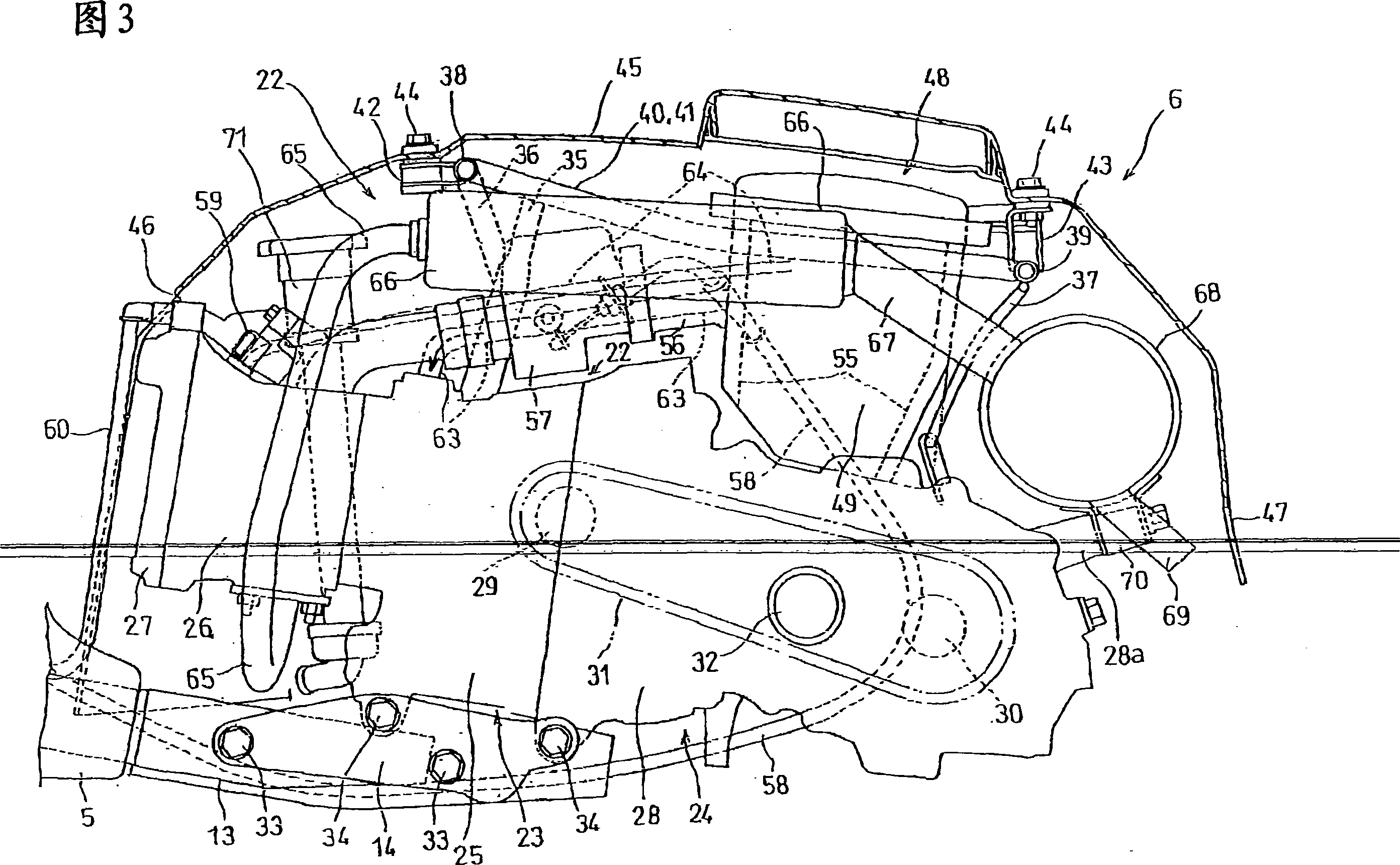

[0037] Embodiments of the invention as claimed in claims 1 to 3 will be described below with reference to FIGS. 1 to 3 .

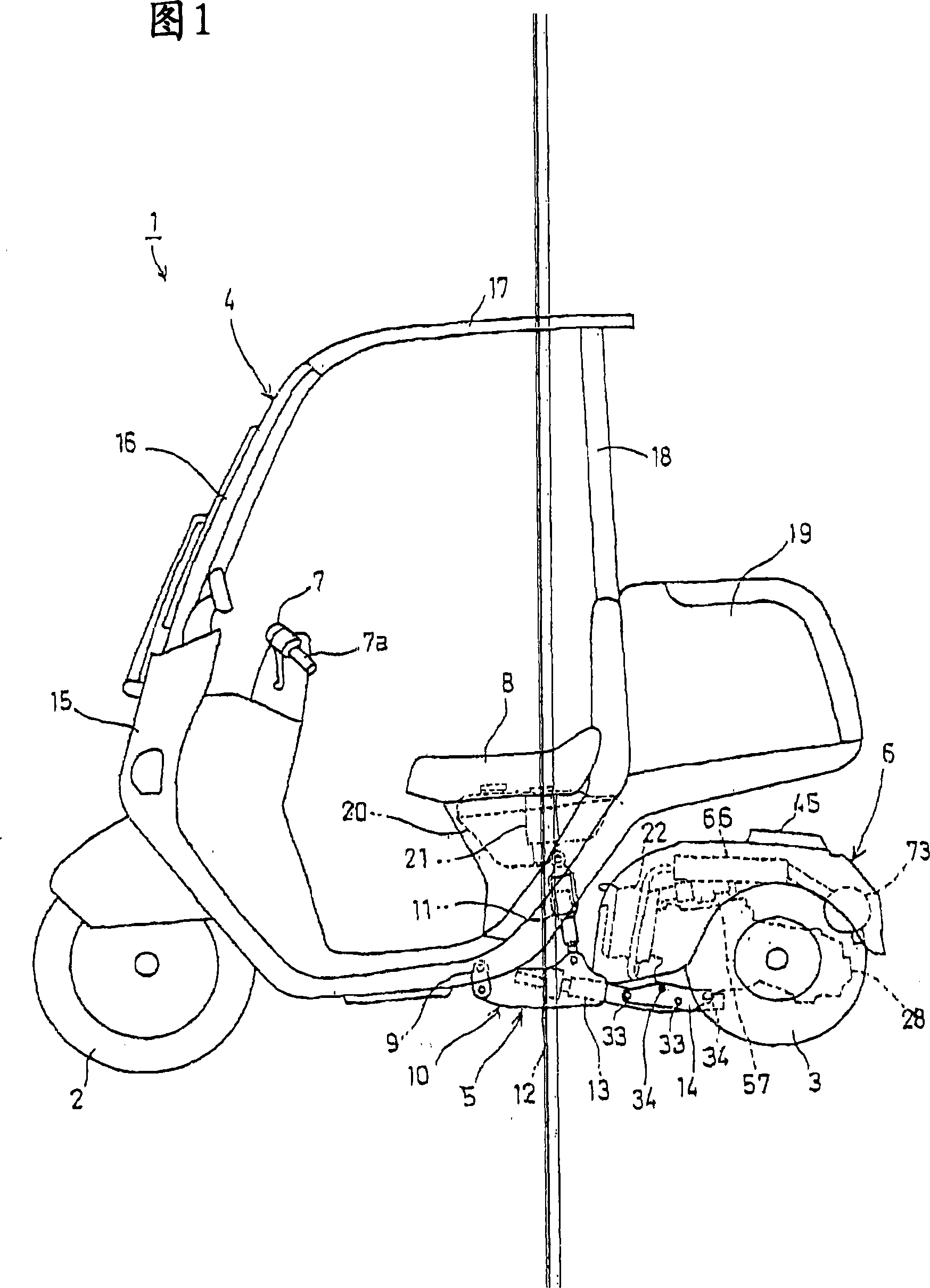

[0038] A three-wheeled motor vehicle as shown in FIG. 1 includes a front wheel 2 and a pair of right and left rear wheels 3 . The front wheels 2 are rotatably mounted to the lower portion of an unillustrated steering shaft pivotally supported in front of the front body 4 in a substantially upright posture. The pair of right and left rear wheels 3 are arranged on both sides of a rear body 6 , which is located behind the front body 4 and connected thereto via a swing mechanism 5 .

[0039] The handlebar 7 that is used to manipulate the front wheel 2 is arranged on the top end of the steering shaft not shown in the figure, and the driver who is sitting on the vehicle seat 8 behind the front body 4 manipulates the handlebar 7, In order to make the front wheel 2 turn right or left.

[0040] Furthermore, the swing mechanism 5 includes: a connection box 10, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com