Continuous precise metal belt measuring X-ray process and equipment

A metal strip and X-ray technology, which is used in the field of continuous high-precision measurement of metal strips and devices using X-rays, can solve problems such as low precision, and achieve stable and reliable, improved speed, and low-loss transmission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

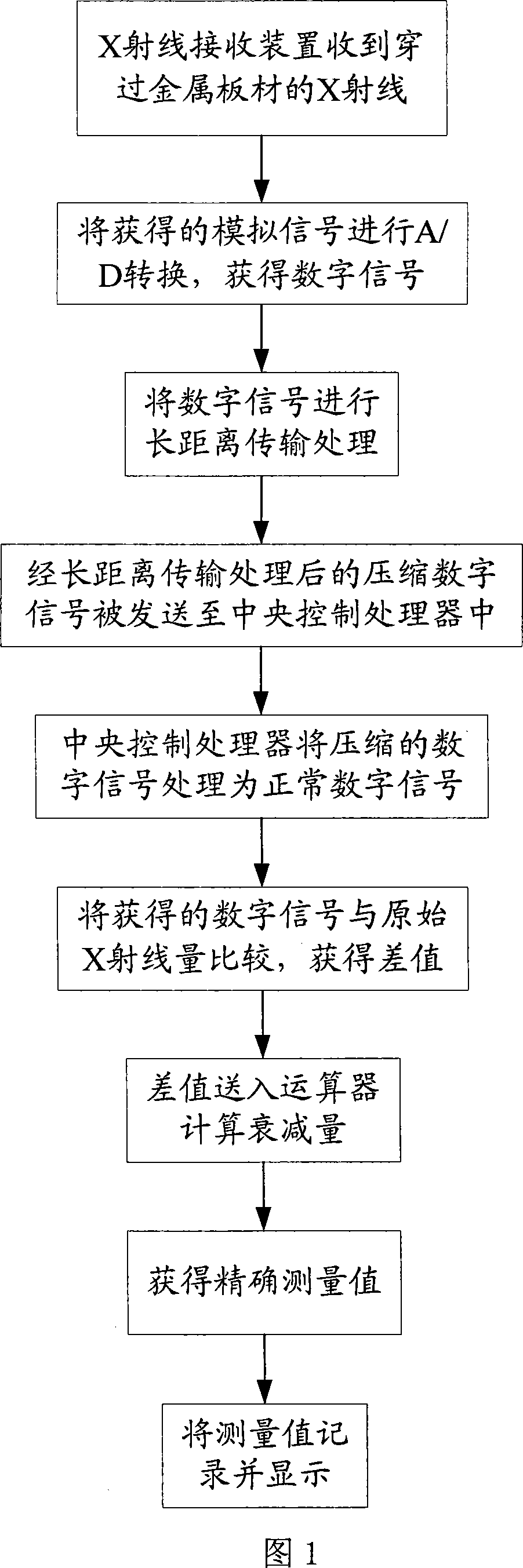

[0022] What this embodiment described is the method for using X-ray continuous high-precision measurement of metal strips, the hardware used includes: arithmetic unit, A / D converter, on-site display, central control processor, output interface, X-ray high-voltage power supply , on-site controller, cooling controller, X-ray source, X-ray detector, measuring transmitter, these hardwares constitute the X-ray measuring instrument, which is a non-contact, non-destructive measuring instrument, and its operation steps:

[0023] 1. The X-ray receiving device receives the X-rays passing through the metal plate, and the signal sent by the X-ray receiving device is a continuous analog signal.

[0024] 2. Perform A / D conversion on the obtained analog signal to obtain a digital signal.

[0025] 3. Carry out long-distance transmission processing of digital signals. In the actual metal strip rolling production line, the X-ray emitting tube and X-receiving device for measurement must be on t...

Embodiment 2

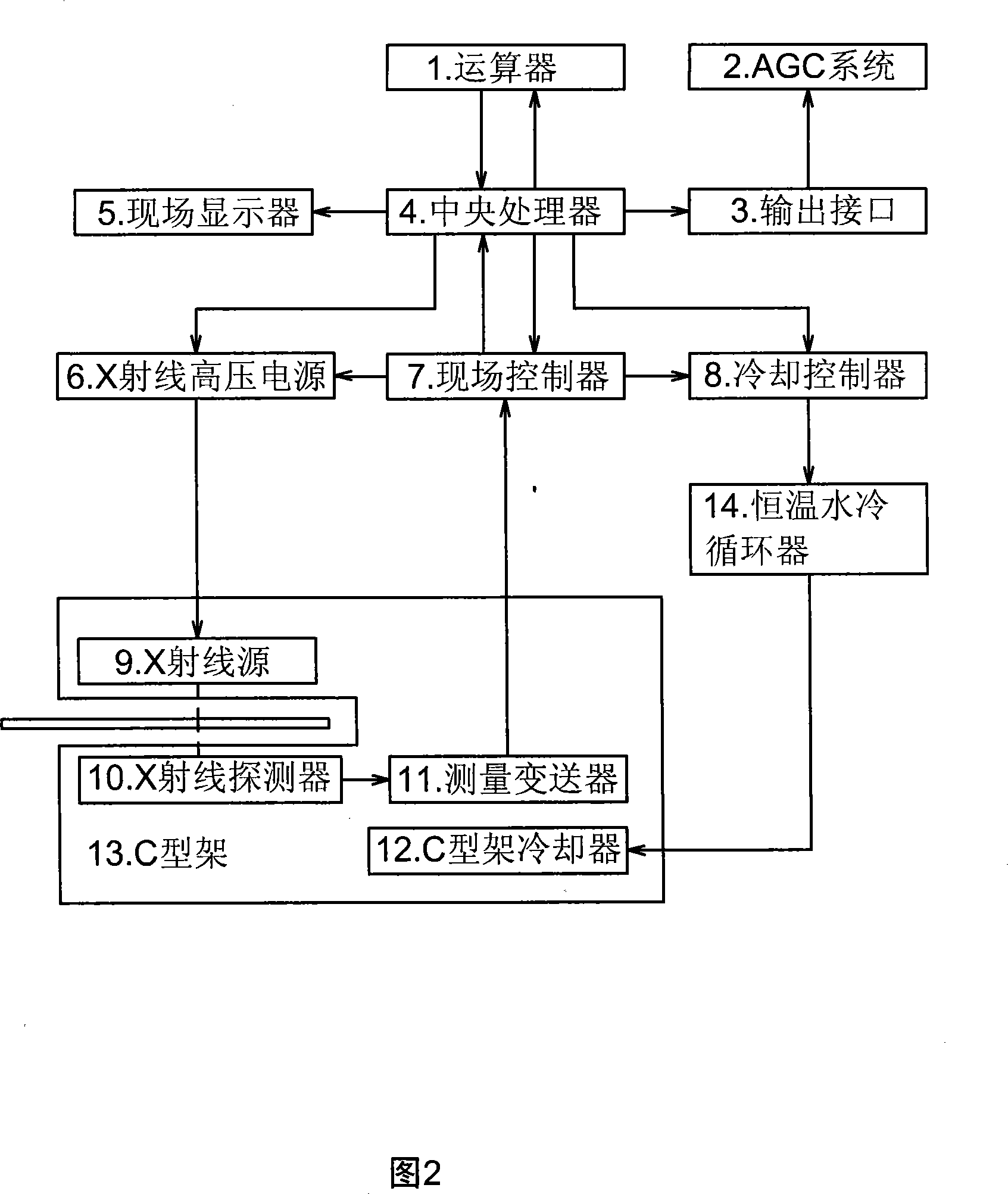

[0034] Fig. 2 is a schematic diagram of the overall structure of a device for continuous and high-precision measurement of metal strips using X-rays in the present invention. The serial numbers in the figure represent: 1. Calculator, 2. AGC system, 3. Output interface, 4. Central control processor, 5. On-site display, 6. X-ray high-voltage power supply, 7. On-site controller, 8. Cooling controller, 9. X-ray source, 10. X-ray detector, 11. Measurement transmitter, 12 .C-frame cooler, 13.C-frame, 14.Constant temperature cooling circulator.

[0035]When X-rays pass through an object, they are attenuated. Correct correction attenuation is the key to accurate measurement. In order to realize high-precision measurement in this embodiment, the analog quantity measured by the X-ray detector 10 is converted into a digital quantity, and the computer, in this embodiment, is the arithmetic unit 1, processes these digital quantities, and corrects the X-ray penetration. The attenuation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com