Methane detecting fiber grating process and equipment

A fiber grating and methane detection technology, which is applied in phase influence characteristic measurement, special data processing applications, instruments, etc., can solve the problems of complex process, low mechanical strength, high cost, etc., and achieve simple replacement process, not easy to be damaged, and mechanical strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

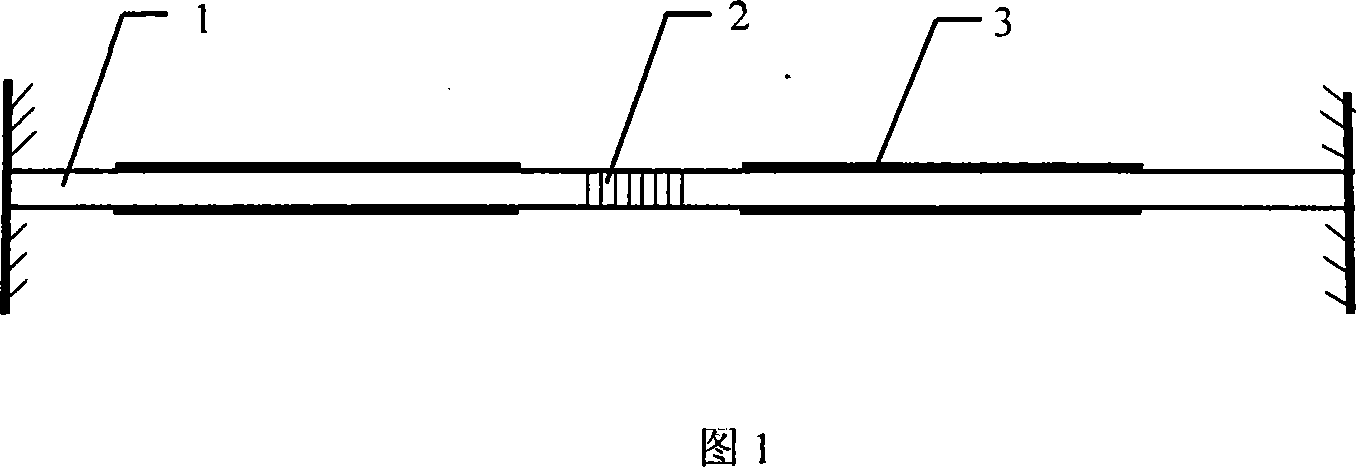

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail, as shown in Figure 1, adopt the grating 2 of certain length on photolithography on a section of optical fiber 1, the reflection peak wavelength of this grating 2 is 3 nanometers, uses on the cladding of optical fiber A platinum film 3 with a width of 3 microns is coated on the vacuum coating technology as a catalyst, thus forming a fiber grating methane sensor 4 . Under the action of the catalyst, methane in the gas to be measured reacts with oxygen in the air to release heat, which increases the temperature near the platinum film 3 and causes the optical fiber 1 to deform, thereby causing the position of the reflection peak of the grating 2 to shift.

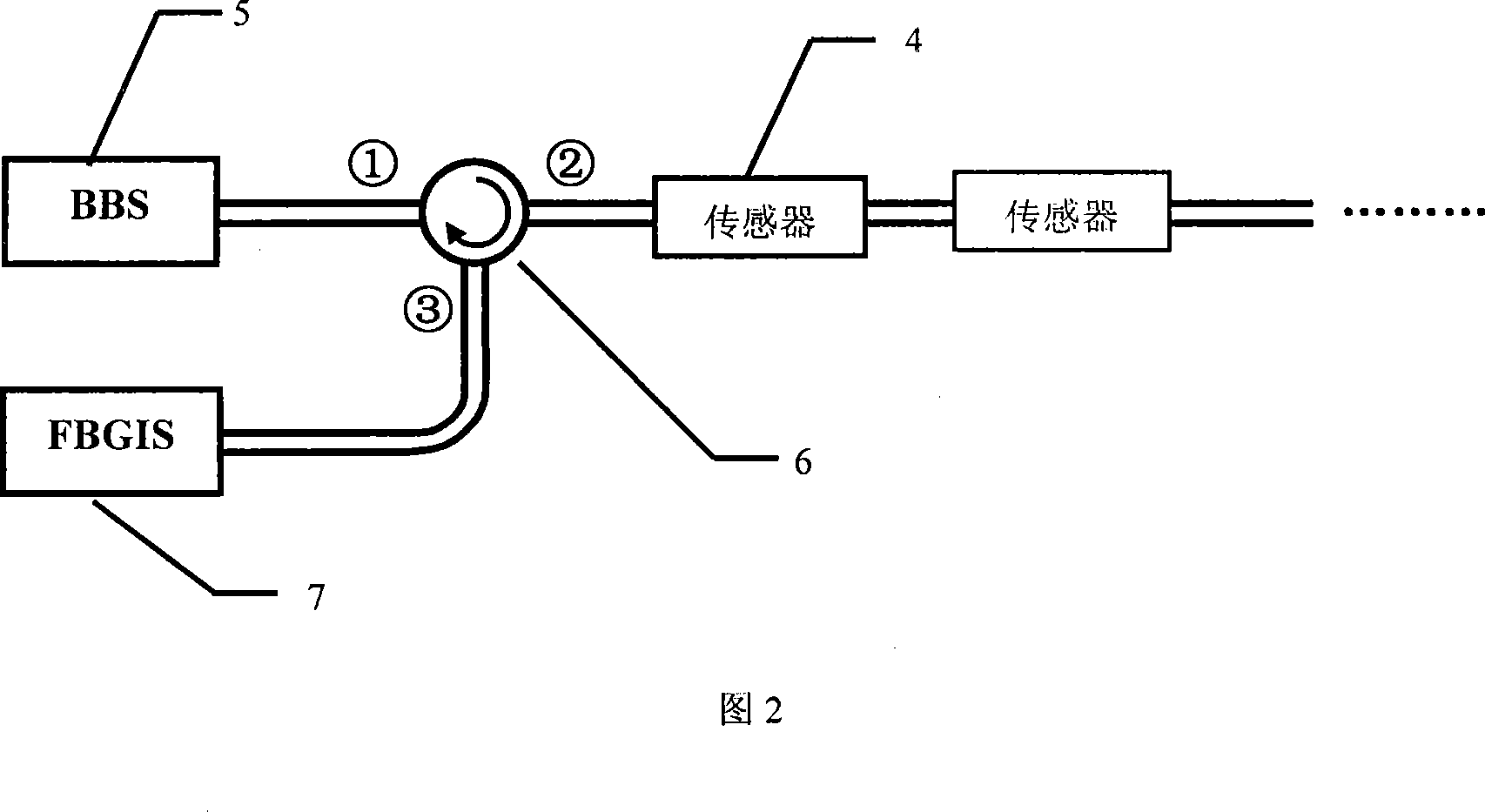

[0022] As shown in Figure 2, select a group of the above-mentioned fiber grating methane sensors 4 with an interval of 3 nanometers of each grating reflection peak wavelength position to be connected in series through an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com