Use straddling microsphere and water as co-foaming agent to prepare low density polyurethane integral surface foam system

A technology of expanding microspheres and polyurethane, which is applied in the field of foam footwear products, can solve the problems that thermoplastic polyurethane is not suitable, foam products are expensive, and low density, and achieve good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

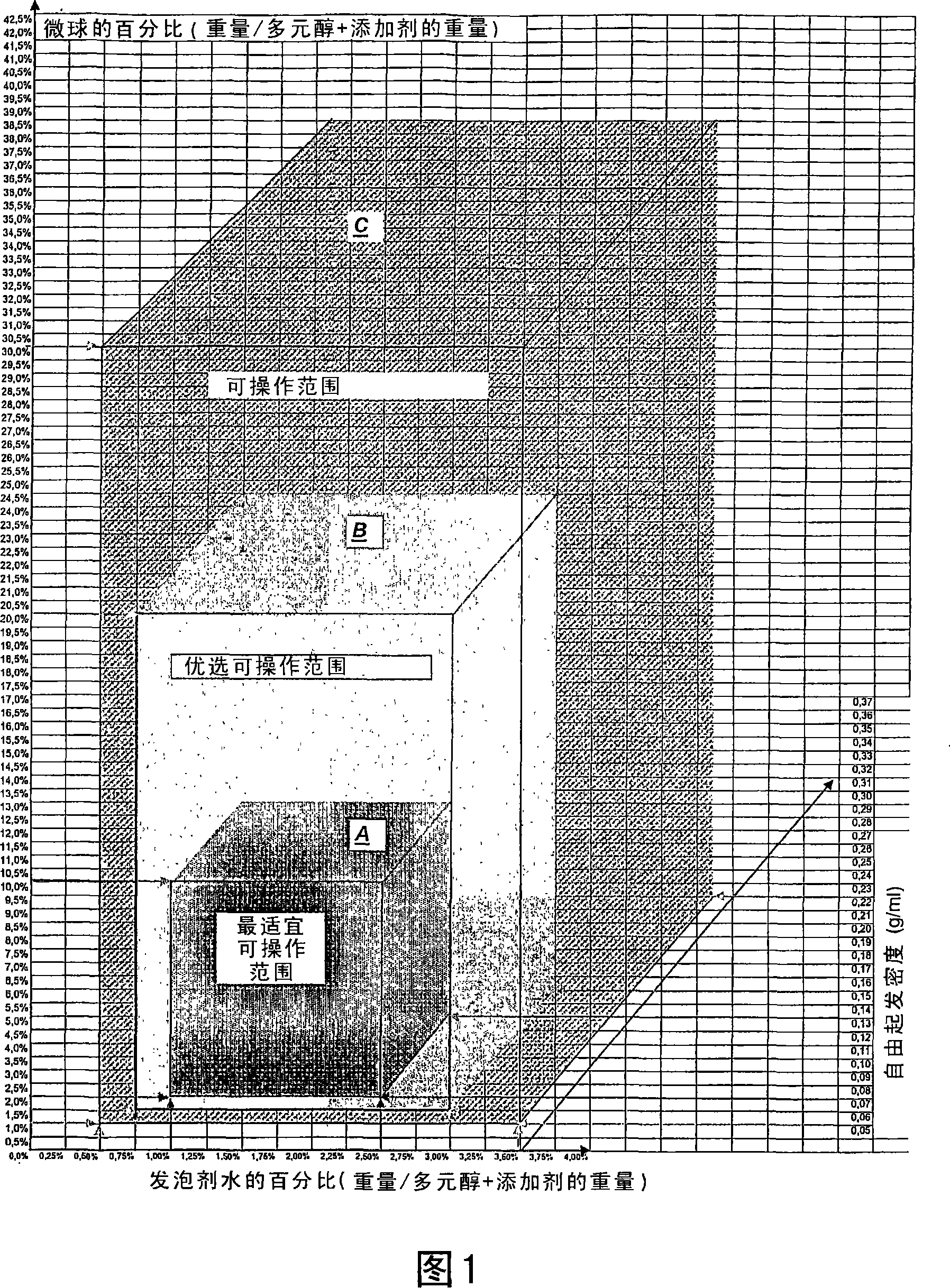

[0054] In the preparation of the material, best results are obtained by first developing microspheres, compounds containing chain extenders (such as MEG), and other additives (catalysts, surfactants, surfactants, and emulsifiers) required for polyurethane foaming. Cell agent, foaming agent and cell regulator) are mixed, and then these compounds are mixed with polyol: the temperature of polyol should not exceed 55-60°C. If compounds with microspheres are mixed with polyols at higher temperatures, the properties of the microspheres may be destroyed because they are at a temperature too close to their "snapshot", which should only happen during the expansion step .

[0055] The molding step was performed by using existing conventional equipment of any type without any modification necessary. Additives, microspheres and water are added to the polyol, the added polyol and isocyanate prepolymer are added to a known mixing head and cast or injected into a mould.

[0056] Keep the t...

Embodiment 1

[0061] Example 1 - Production of sandal soles

[0062] 550 g of "lipid" polyester resin with MW 2000 and OH number 56 were mixed with 200 g of polymeric resin with MW 2500 and OH number 60, 150 g of dicarboxy resin with MW 2000 and OH number 60, 130 g of chain extender (monoethylene glycol ), 11 g of triethanolamine, 13 g of ammonia delayed catalyst (Dabco), a small amount of pore regulator and emulsifier, 1% (10.5 g) of expandable microspheres and 0.69% (7.5 g) of water were mixed. This mixture of polyol+additives and water and microspheres was reacted with 1200 g of an MDI based prepolymer having an NCO of 23% and a functionality of 2.03.

[0063]After free-rise casting, the following values were obtained (time zero is the start of casting): milky phase: 7 seconds; microsphere expansion time: start at 10 seconds and end at 18 seconds; end of rise time: 50 seconds ; Initial temperature: 50°C; Maximum temperature: 110°C; Free rise density: 0.12g / ml.

[0064] The same compo...

Embodiment 2

[0067] Embodiment 2 - be used for the production of sports shoe insole

[0068] The polyurethane system of Example 1 was used, but the amount of microspheres was 8% by weight and the amount of water was 2.2% by weight.

[0069] The free rise density obtained with this formulation was 0.07 g / ml, and, despite the increased amounts of microspheres and water, the reaction was slow enough to result in controlled and uniform filling of the mold, with no cracks or cracks in the final product. "Stomata" (air entrainment).

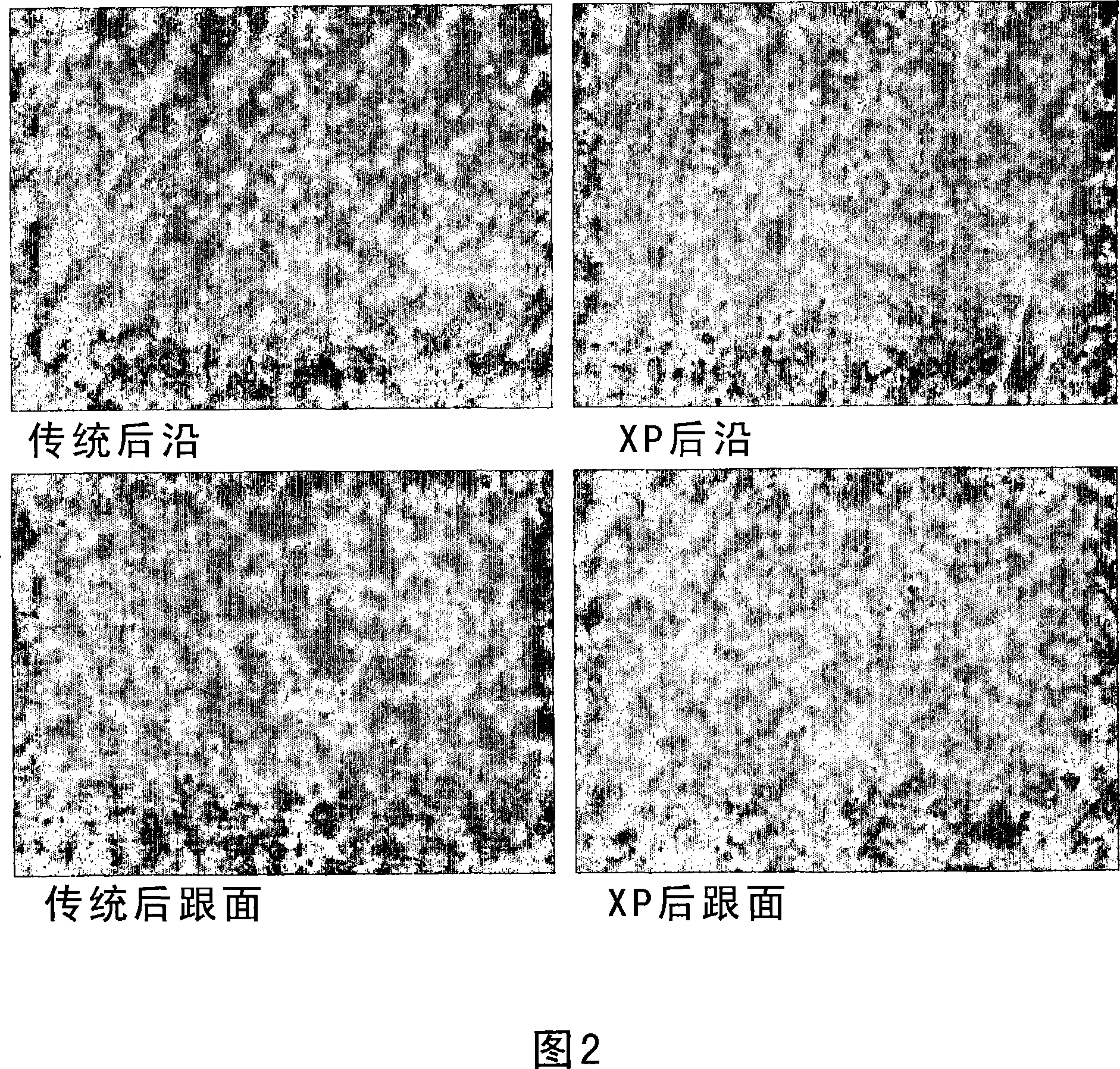

[0070] The following table shows the comparison of the known method and the method of the present invention and the final characteristics of the product of Example 2.

[0071] prior art methods

The method of the invention

35℃

45℃

35℃

45℃

Isocyanate / Polyol Ratio

80

100

110

100

35 SHOREA

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com