Semi solid metal apparent viscosity detector

A semi-solid metal, apparent viscosity technology, applied in measuring devices, flow characteristics, instruments, etc., can solve the problems of easily damaged torque sensors, drastic changes in the temperature field in the furnace, large torque impact values, etc., to prevent alloy oxidation. , Improve the thermal conductivity, the effect of small temperature disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] Example 1. Measurement of AlSi 4 Mg 2 Apparent Viscosity of Aluminum Alloy Semi-solid Paste

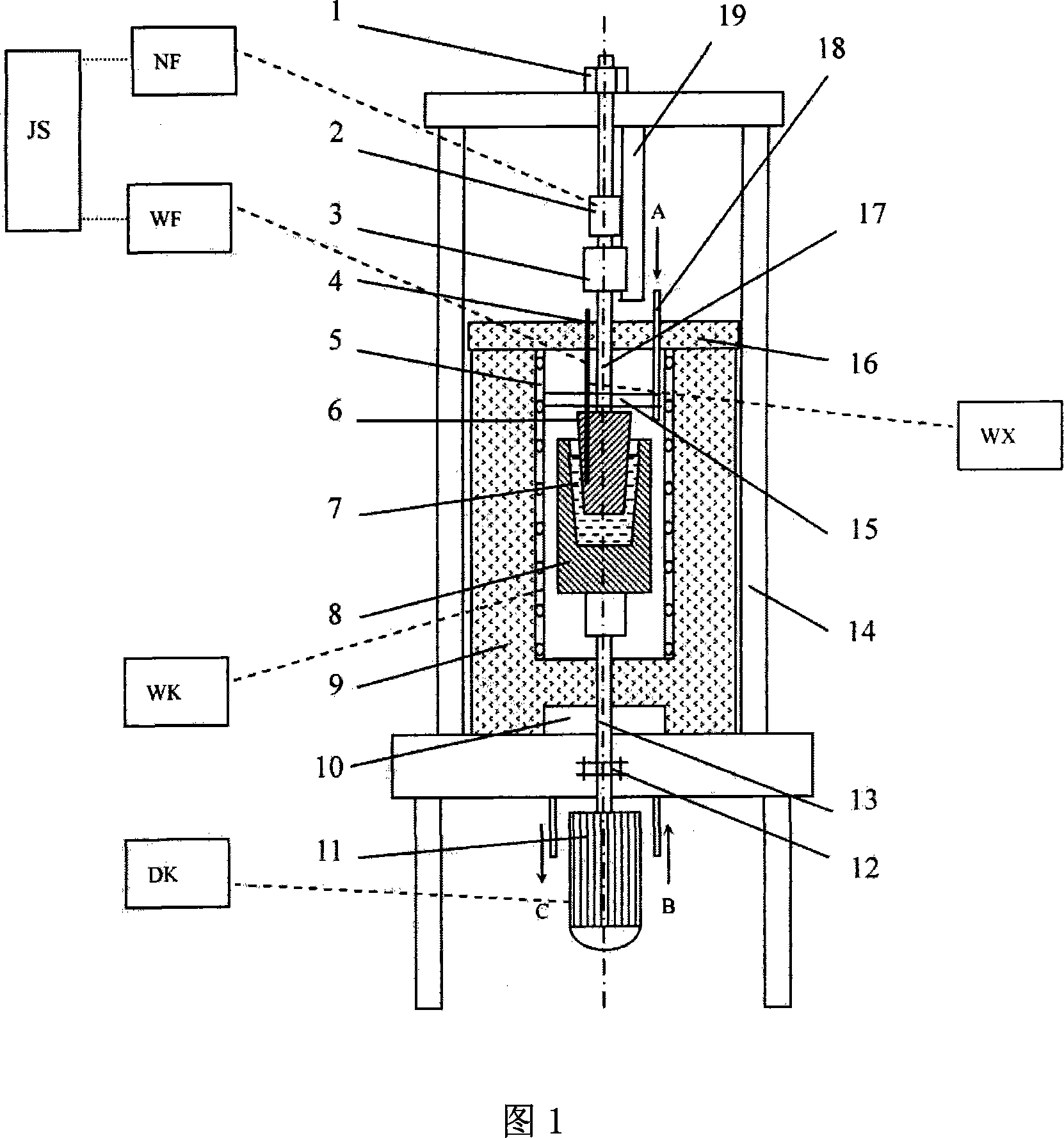

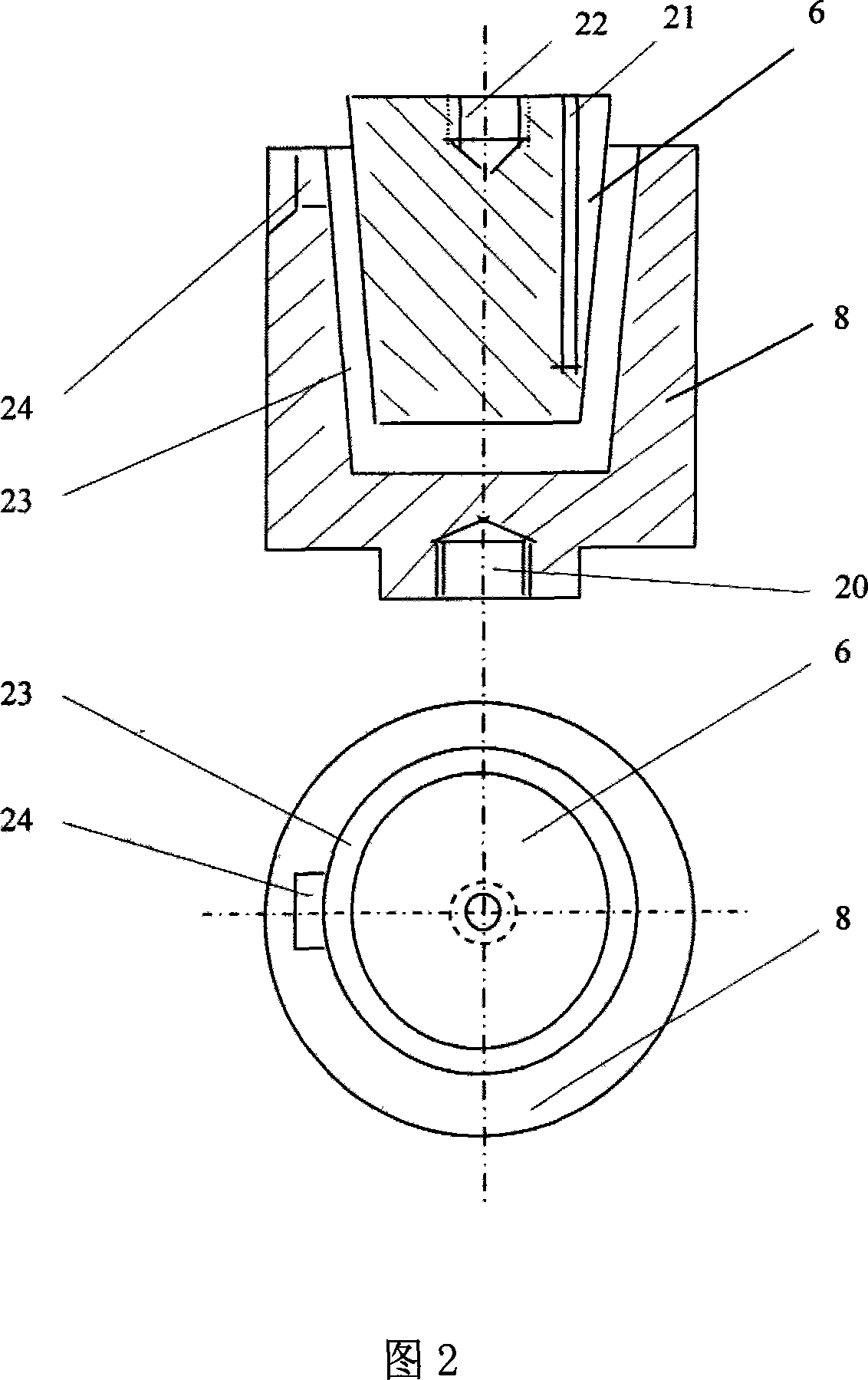

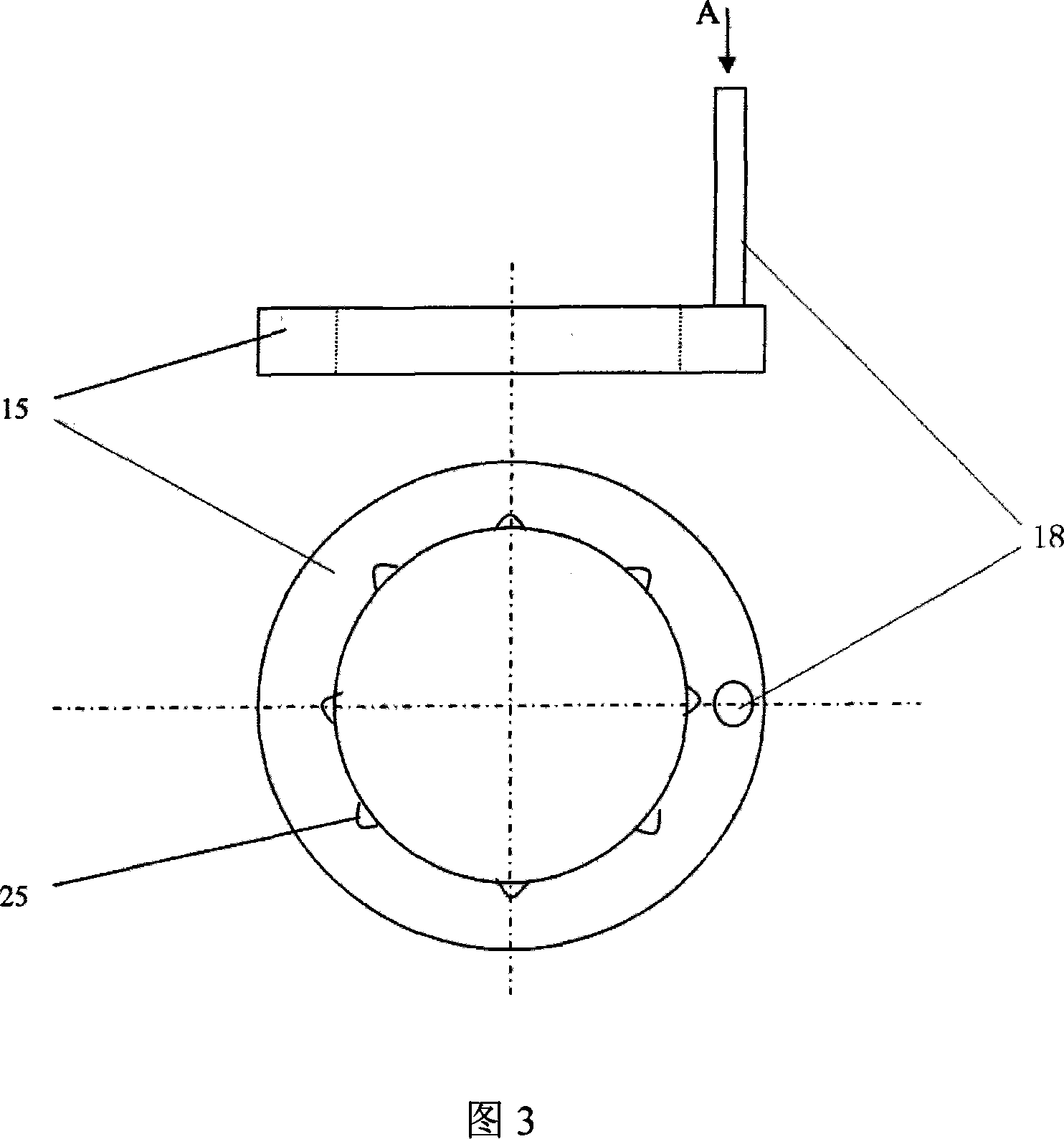

[0015] As shown in Figure 1, the resistance furnace 9 is installed on the frame 14, and a crucible 8 made of graphite is installed in the resistance furnace 9 cavity. The rotating shaft 13 of the crucible 8 is connected with threads, and the lower end of the rotating shaft 13 is connected with the output shaft of the high-frequency speed-regulating motor 11 through a coupling 12. The high-frequency speed-regulating motor 11 is placed at the lower part of the resistance furnace 9 and fixed on the base In the center of the crucible 8 cavity, there is an approximately cylindrical graphite head 6 installed in the air. An annular cavity for filling metal raw materials is formed between the inner wall of the crucible 8 and the graphite head 6. The graphite head 6 and the crucible 8 are coaxial. The center of the upper end of the graphite head 6 is threaded with a threaded hole 22 a...

example 2

[0027] Example 2. Measuring the apparent viscosity of AZ91D magnesium alloy semi-solid slurry

[0028] According to the implementation steps of Example 1, for the AZ91D magnesium alloy, during the solidification process with a cooling rate of 4°C / min, respectively at a shear rate of γ=46.8s -1 , 93.6s -1 , 187.2s -1 and 280.8s -1 Continuous shear was performed to measure the apparent viscosity at different temperatures (ie, different solid phase fractions), and a metallographic sample of the semi-solid slurry was obtained, as shown in FIG. 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com