Ultrasonic Stirring Composite Melting Equipment for Low Melting Point Alloys

A technology of ultrasonic stirring and smelting equipment, which is applied in the field of low melting point alloy ultrasonic stirring compound smelting equipment, alloy smelting and preparation, and can solve the problems of serious ultrasonic attenuation, affecting the uniformity of the melt, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

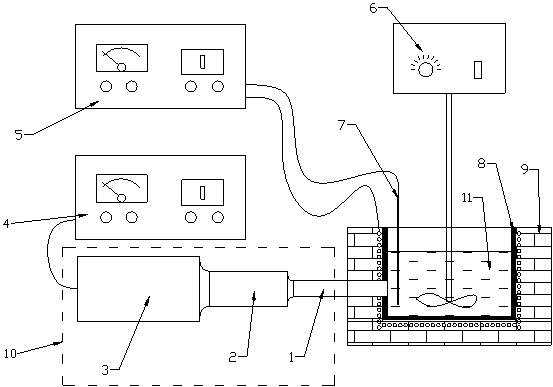

[0015] Attached below figure 1 The present invention is described further:

[0016] Such as figure 1 As shown, the low-melting point alloy ultrasonic stirring compound melting equipment includes a crucible 8, a heat preservation heating device 9, a temperature control device 5, and an ultrasonic stirring device 10 (the working head 1, the horn 2, and the ultrasonic transducer 3 are integrated. It is composed of an integrated structure connected by threads), an ultrasonic generation and control device 4 and a mechanical stirring device 6. The temperature control device 5 is connected to the heat preservation heating device 9 and the temperature measuring probe 7 respectively, the heat preservation heating device 9 is outside the crucible 8, the temperature measuring probe 7 is inserted into the metal melt 11, and the temperature control device 5 can control the temperature of the metal melt 11. The ultrasonic generation and control device 4 is connected with the ultrasonic st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com