Continuously absorbing and rectifying organic waste recovering method

A technology of organic waste gas and recovery method, applied in chemical instruments and methods, separation methods, vapor condensation and other directions, can solve the problems of large consumption, large energy, consumption, etc., and achieve the effects of convenient operation, high recovery rate and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

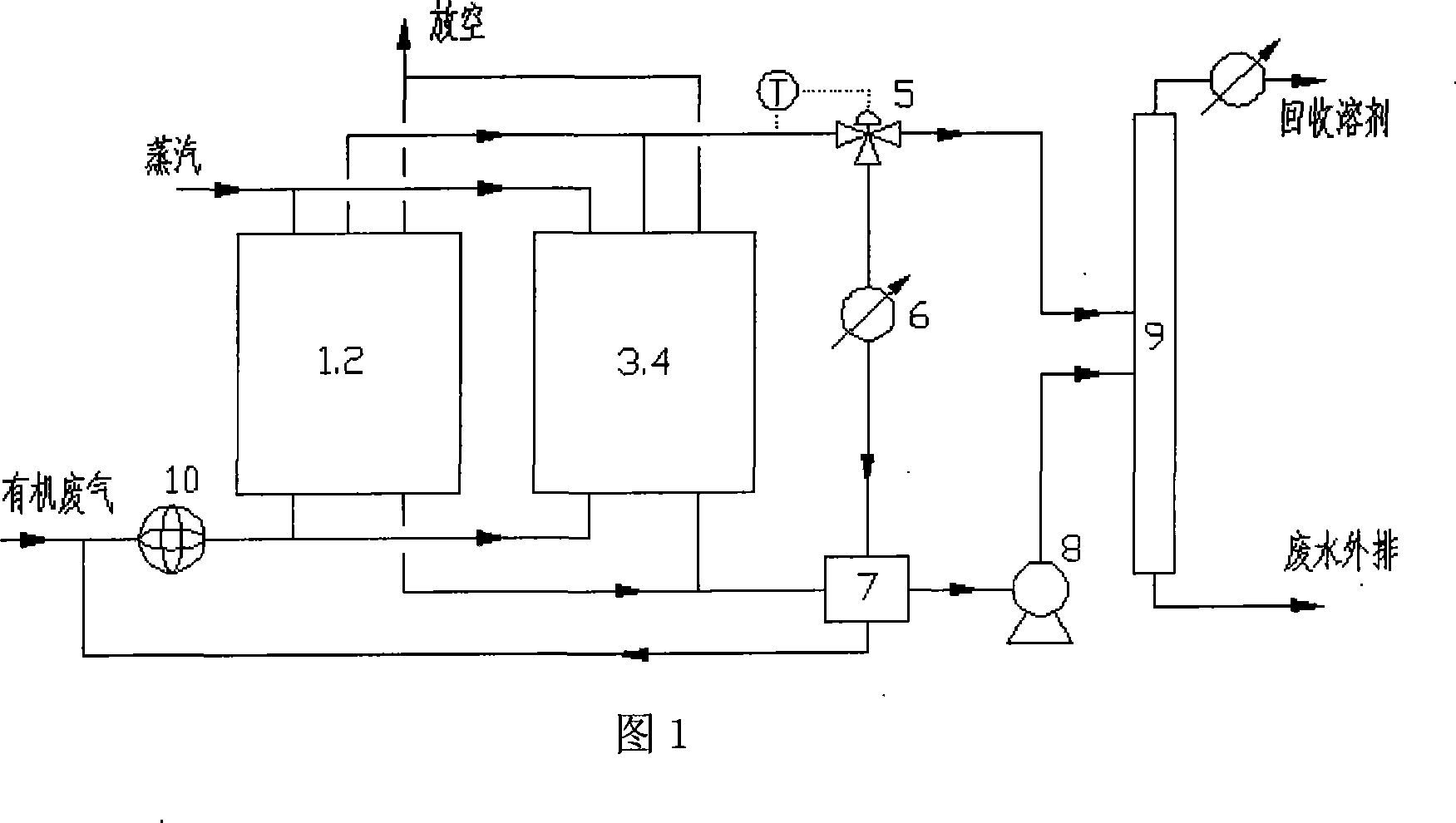

[0010] Example 1, the ethanol waste gas discharged by a printing enterprise, the air volume is 12000m 3 / h, concentration 10g / m 3 , carry out adsorption recovery with activated carbon fiber, design four adsorption boxes (using 640kg activated carbon fiber, each adsorption box is filled with 160kg activated carbon fiber. According to the original process, two adsorption boxes are designed, and each adsorption box uses 320kg activated carbon fiber), ), the steam used for desorption is 300kg / h, and the desorption steam directly enters a ¢500×12000 rectification tower, and after rectification, ethanol with a content meeting the production requirements is obtained, saving more than 300kg of steam per hour, and saving 160m of circulating cooling water 3 / h.

Embodiment 2

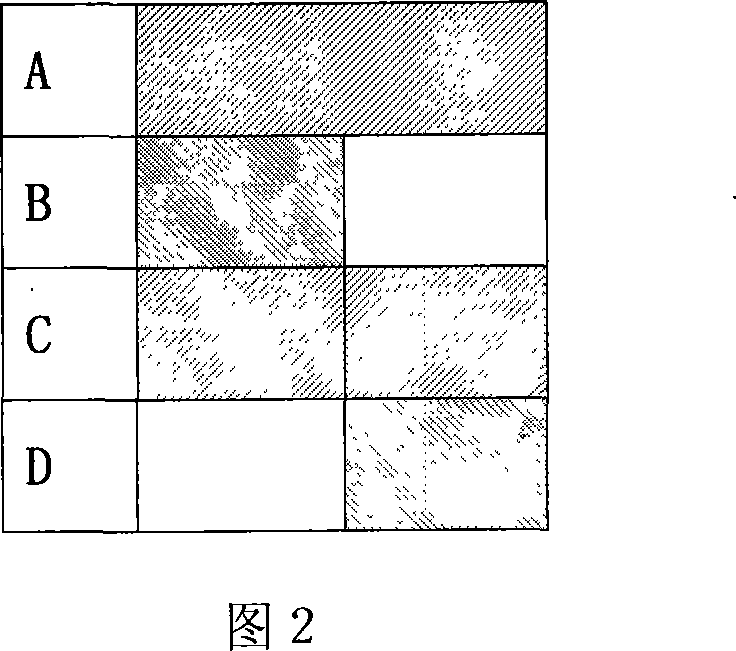

[0011] Example 2, the methanol waste gas discharged by a chemical enterprise, the air volume is 1500m 3 / h, concentration 45g / m 3 , four adsorbers are designed with activated carbon fiber adsorption and recovery, each adsorber is filled with 80kg activated carbon fiber, the adsorption time is 20min, the desorption time is 10min, the drying time is 5min, the desorption air discharge time is 3min, the intermittent time is 2min, and the desorption steam directly enters the packing rectification More than 99% of the methanol obtained through column rectification can be reused in production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com