Flow-disturbing type air inlet pipe of muffler

A technology of intake pipe and muffler, which is applied in the direction of muffler, machine/engine, engine components, etc. It can solve the problems of insufficient combustion of mixture gas, power loss, increase of pollutant emissions, etc., and achieves simple structure and is conducive to production and installation , Beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

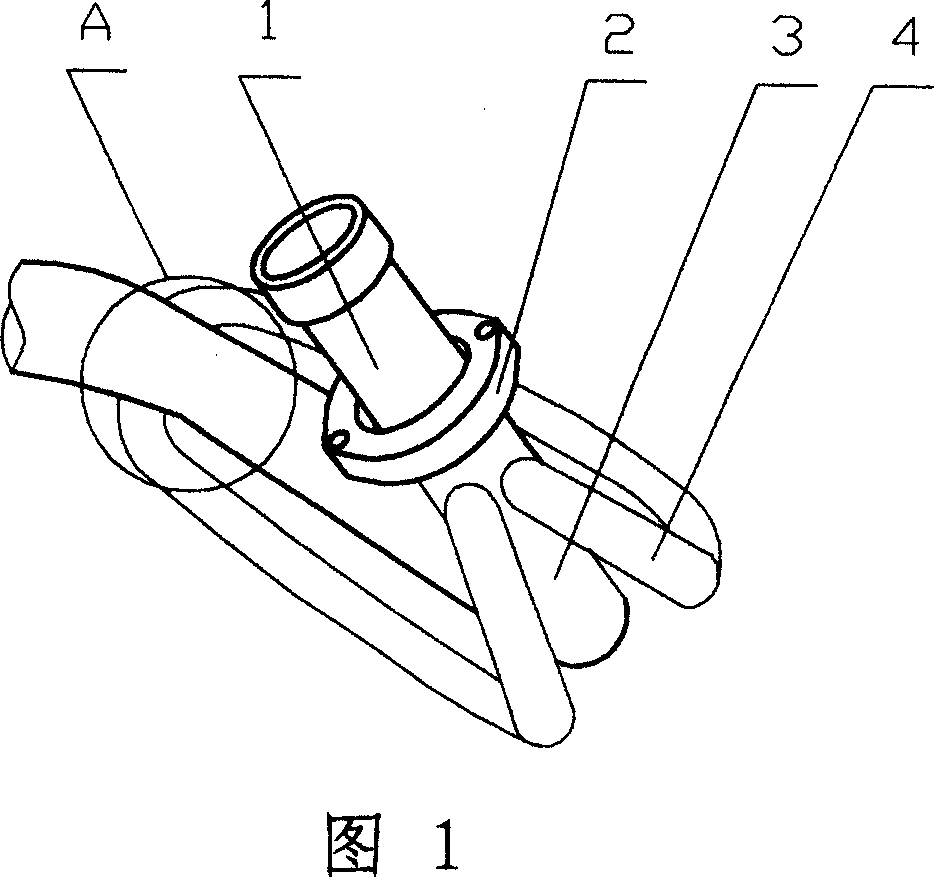

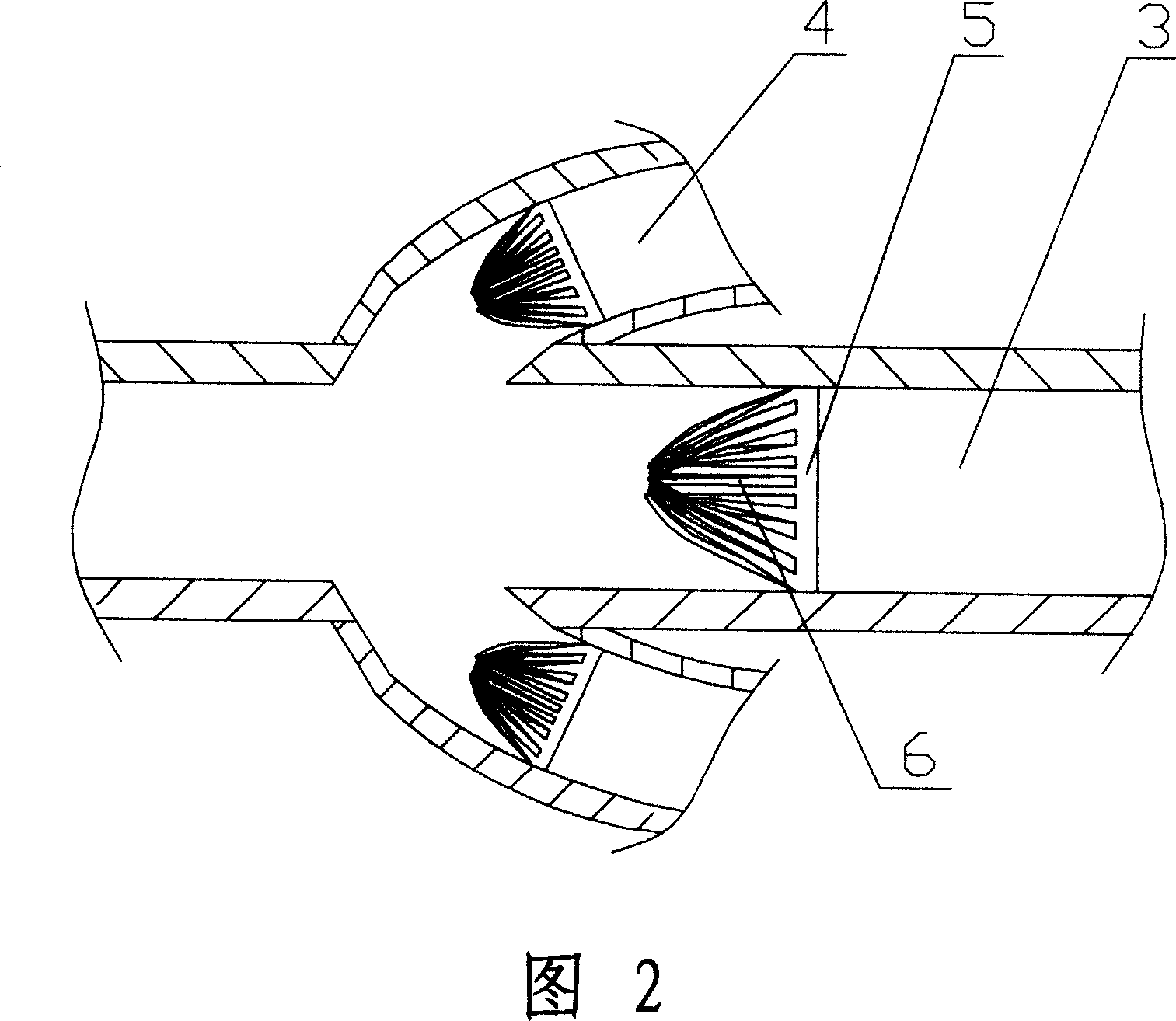

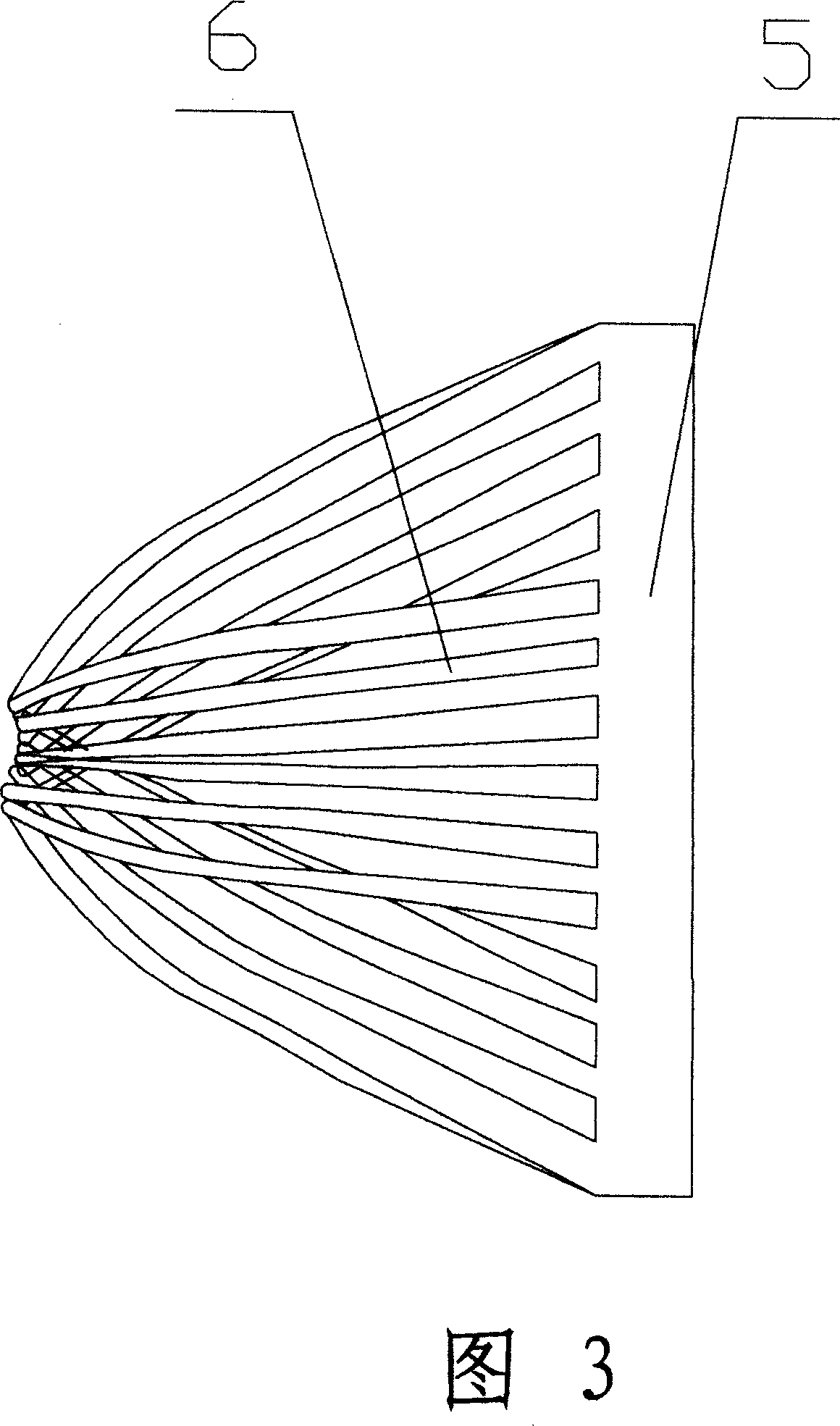

[0010] Referring to Figure 1, Figure 2, and Figure 3, a flange 2 is provided at the inlet end of the inlet pipe 1 of the muffler. The air inlet pipe 1 is formed by welding two curved ducts 4 for turbulence on a curved main airflow duct 3, and the two ducts 4 for turbulence are juxtaposed on both sides of the main airflow duct 3. The head and tail ends of 4 are welded to the wall of the main air duct 3 and communicate with the main air duct 3. The head ends of the two turbulent ducts 4 for flow splitting are welded to the circumference of the same section of the main airflow duct 3 close to the flange plate 2. The end and the main airflow duct 3 form an angle of less than 45 degrees; the tail ends of the two turbulent ducts 4 for turbulence are welded to the main airflow duct 3 on the same section of the circumference close to the muffler tube, two The tail end outlets of the turbulence duct 4 for turbulence are arranged symmetrically opposite to each other centered on the main air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com