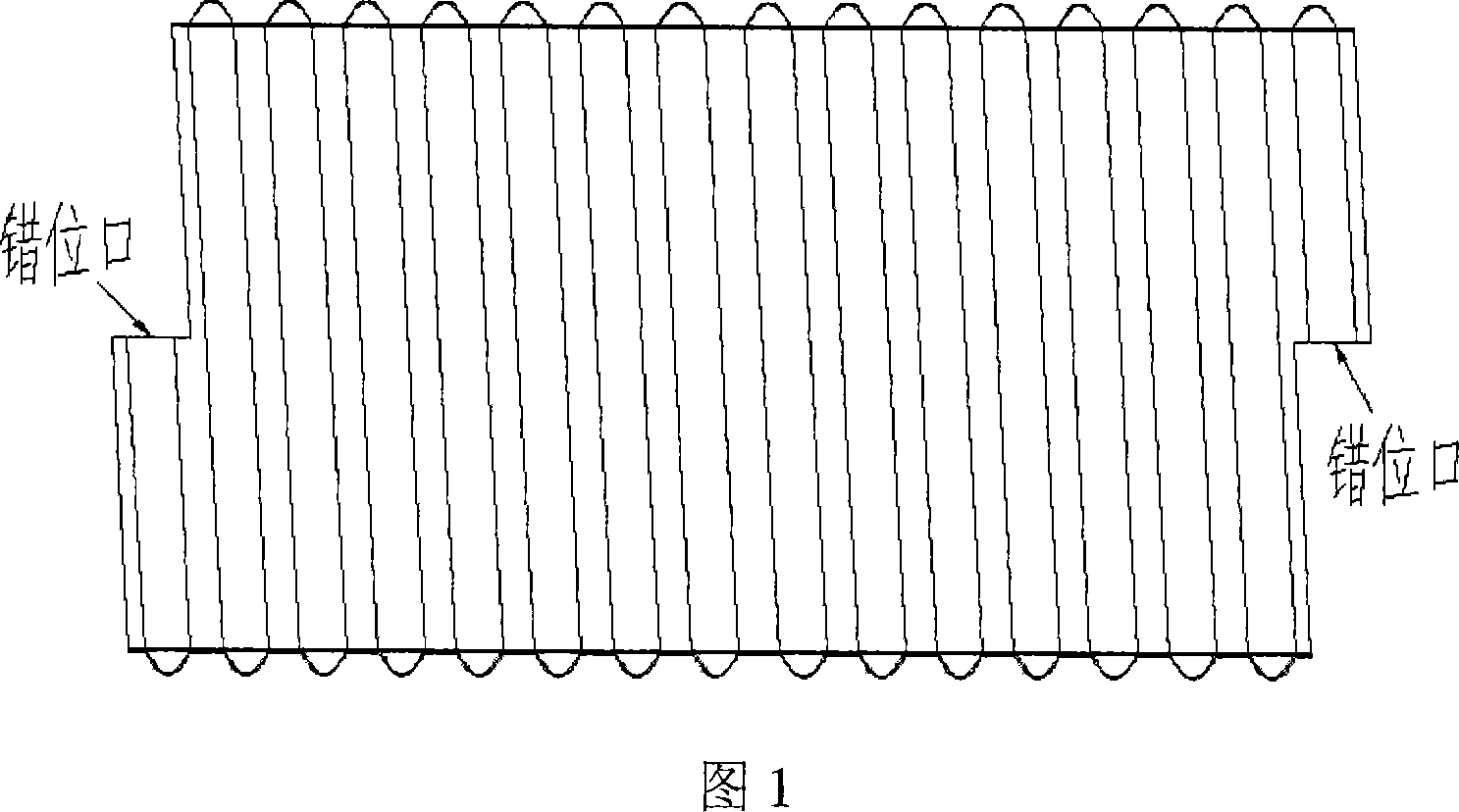

Connection method of steel band reinforced spiral ripple pipe

A technology of spiral corrugated pipe and connection method, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of unrealistic welding of extrusion welding torch, troublesome placement, leakage, etc., and achieve excellent sealing performance , Easy installation and construction, reliable pipe connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

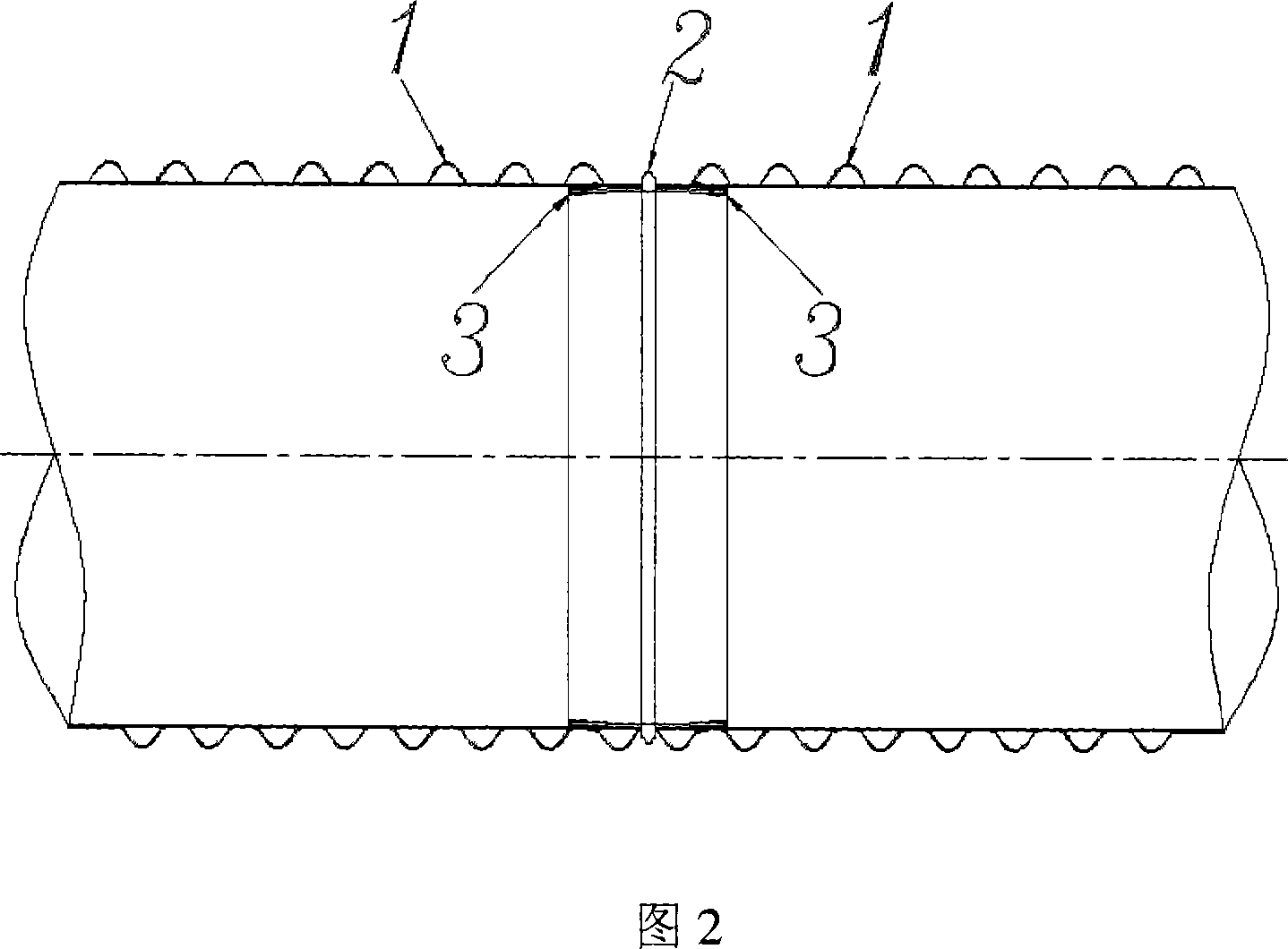

[0025] The connection diagram of the present invention is shown in Figure 2. Two steel belt reinforced polyethylene spiral corrugated pipes 1 are connected through a plug 2 with a sealing ring 3 for internal socket connection.

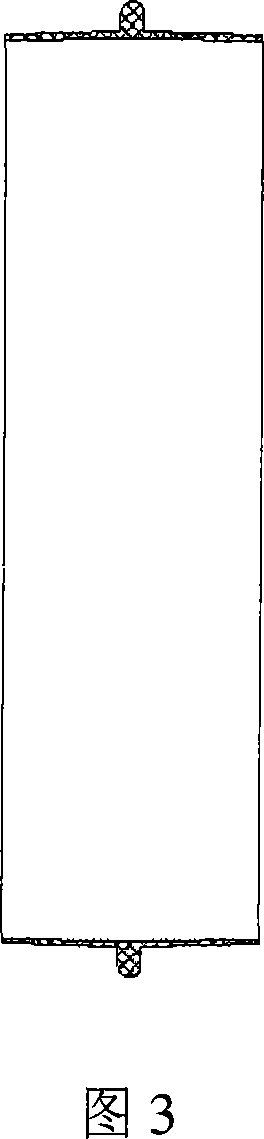

[0026] The structural schematic diagram of the plug is shown in Figure 3. It is made of glass fiber reinforced plastic material, in a cylindrical shape, and its outer diameter is slightly smaller than the inner diameter of the steel belt reinforced polyethylene spiral corrugated pipe 1, and a protrusion is provided in the middle as a stop.

[0027] The structural diagram of the sealing ring is shown in Figure 4, in which Figure 4a is an integral sealing ring, while Figure 4b is a split sealing ring. When using an integral sealing ring, only one sealing ring 3 is required to cover the The plug 2 is acceptable, and when a split-type sealing ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com