Low-hardness single-component conductive glue and preparation and application methods thereof

A conductive glue, low hardness technology, applied in conductive materials, conductive adhesives, circuits and other directions dispersed in non-conductive inorganic materials, can solve the problems of weak elastic properties, unfavorable compression operation, increased resistance, etc., to achieve excellent Elasticity, excellent electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

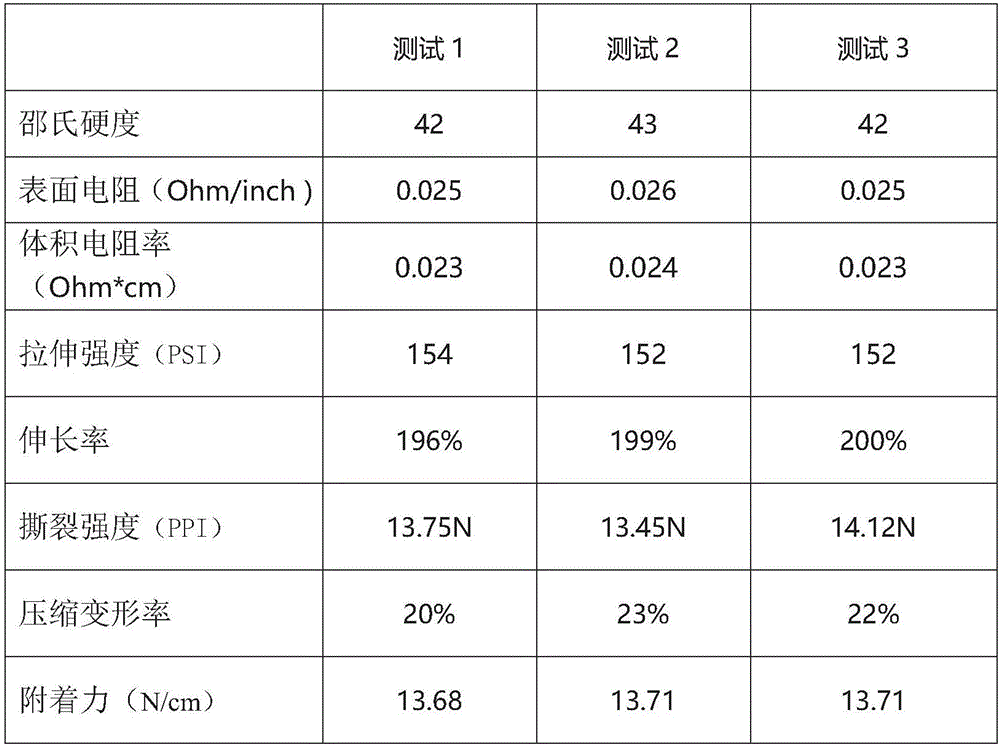

Embodiment 1

[0013] This embodiment is used as a preferred solution. The low-hardness single-component conductive glue is composed of the following components: resin composition, organic solvent and nickel-coated graphite conductive powder. The resin composition is composed of the following specific gravity: vinyl-terminated polydimethylsiloxane 25% alkane, 5% hydrogen-silicon bond polysiloxane oil, 0.1% polymerization inhibitor, and 1% capsule-coated platinum complex; the weight ratio of the resin composition to the nickel-coated graphite conductive powder is 31 / 62; The weight of the organic solvent mentioned is 22% of the weight of the resin composition. In the above-mentioned encapsulated platinum complex, it uses microcapsule technology to completely cover the internal platinum complex with a continuous film of various natural or synthetic polymer compounds to prevent direct contact with hydrogen silicon at room temperature. The bonded polysiloxane oil reacts, and the coating is react...

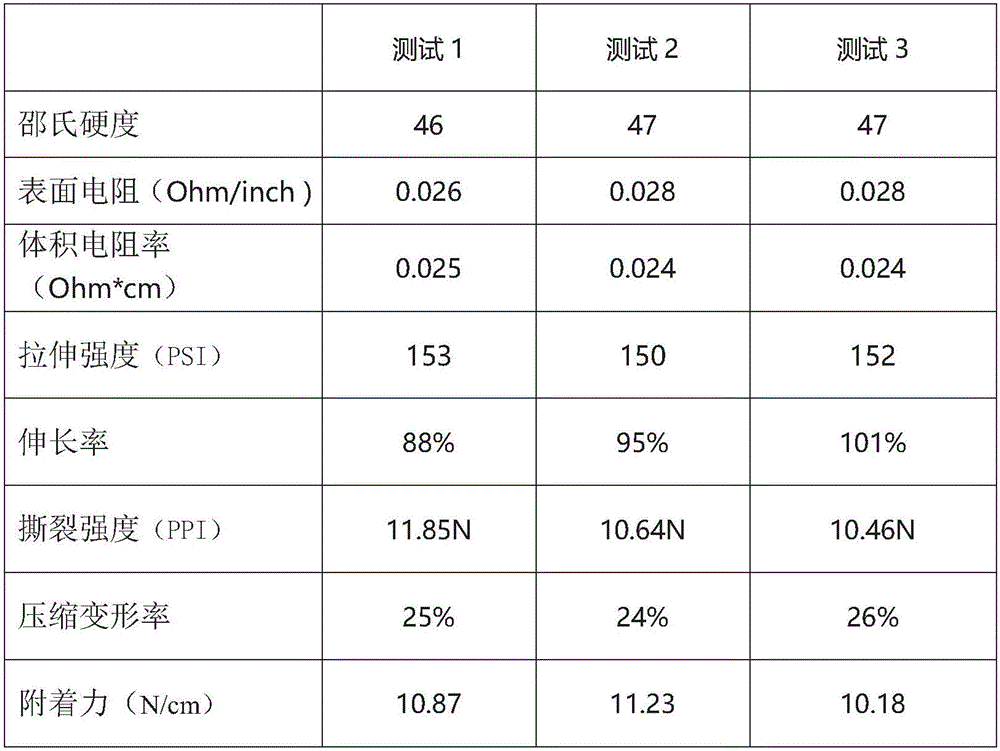

Embodiment 2

[0018] Low-hardness single-component conductive glue, consisting of the following components: resin composition, organic solvent and nickel-coated graphite conductive powder, the resin composition is composed of the following specific gravity: vinyl-terminated polydimethylsiloxane 20%, hydrogen-silicon bonded polysiloxane oil 10%, polymerization inhibitor 0.1%, and capsule-coated platinum complex 0.5%; the weight ratio of the resin composition to the nickel-coated graphite conductive powder is 31 / 60; the described The weight of the organic solvent is 30% of the weight of the resin composition.

[0019] As a further description of the above-mentioned low-hardness single-component conductive glue, the nickel-coated graphite conductive powder is an irregular circular or oval powder with a thickness of 50-150 μm.

[0020] A method for preparing the low-hardness one-component conductive glue, the steps are: put the resin composition and organic solvent into a sealed stirring device...

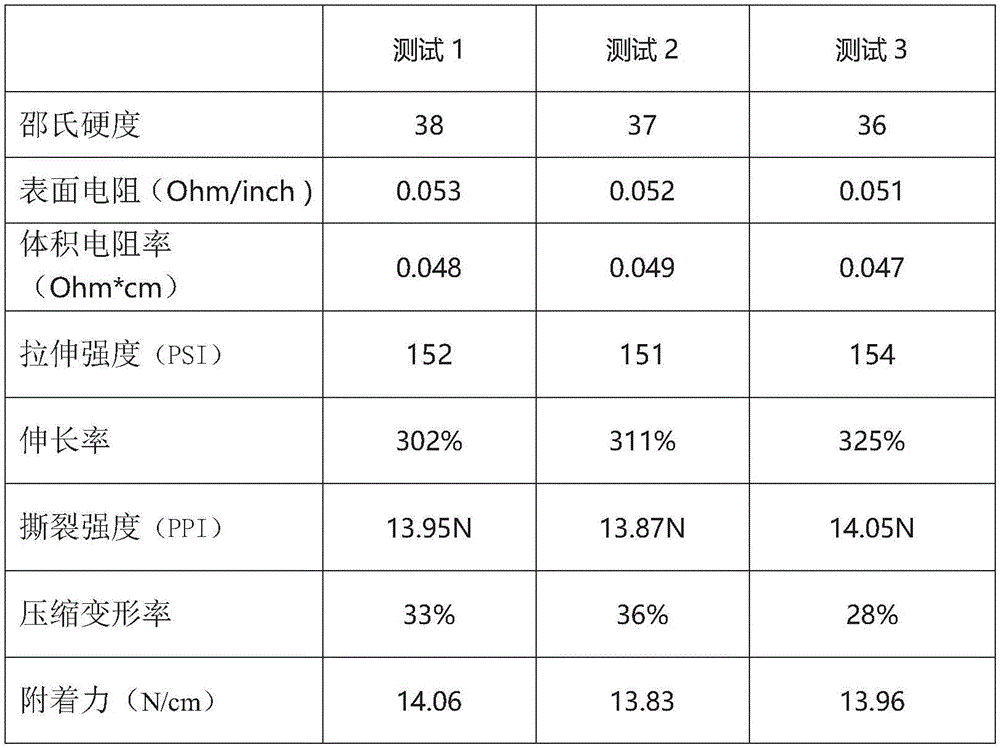

Embodiment 3

[0023] Low-hardness single-component conductive glue, consisting of the following components: resin composition, organic solvent and nickel-coated graphite conductive powder, the resin composition is composed of the following specific gravity: vinyl-terminated polydimethylsiloxane 40%, hydrogen-silicon bonded polysiloxane oil 15%, polymerization inhibitor 0.15%, and capsule-coated platinum complex 1%; the weight ratio of the resin composition to the nickel-coated graphite conductive powder is 56 / 40; the described The weight of the organic solvent is 7% of the weight of the resin composition.

[0024] As a further description of the above-mentioned low-hardness single-component conductive glue, the nickel-coated graphite conductive powder is an irregular circular or oval powder with a thickness of 50-150 μm.

[0025] A method for preparing the low-hardness one-component conductive glue, the steps are: put the resin composition and organic solvent into a sealed stirring device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com